Luminous glass and manufacturing method thereof

A technology of luminescent glass and a manufacturing method, which is applied in the field of luminescent materials and can solve problems such as low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

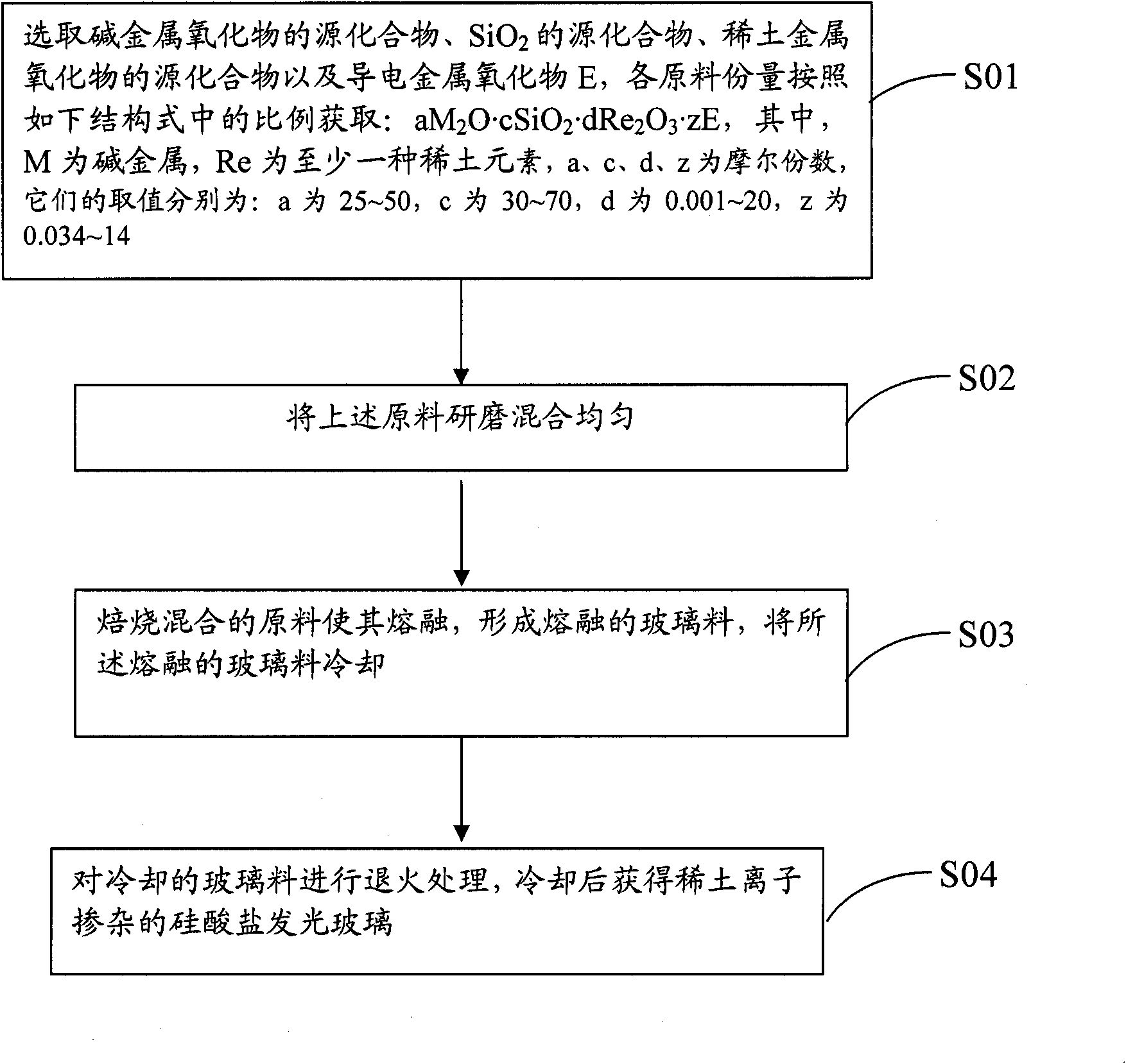

Method used

Image

Examples

Embodiment 1

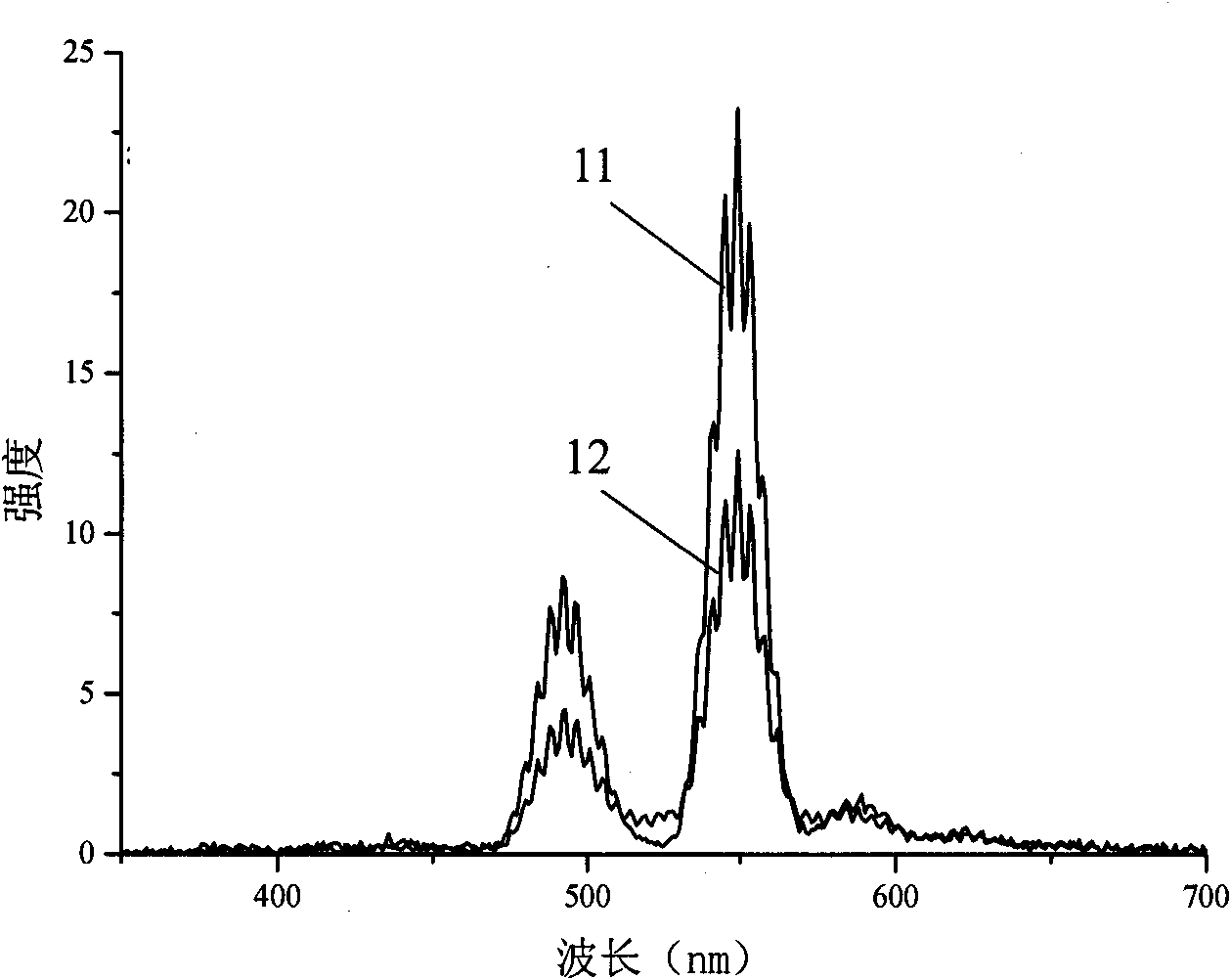

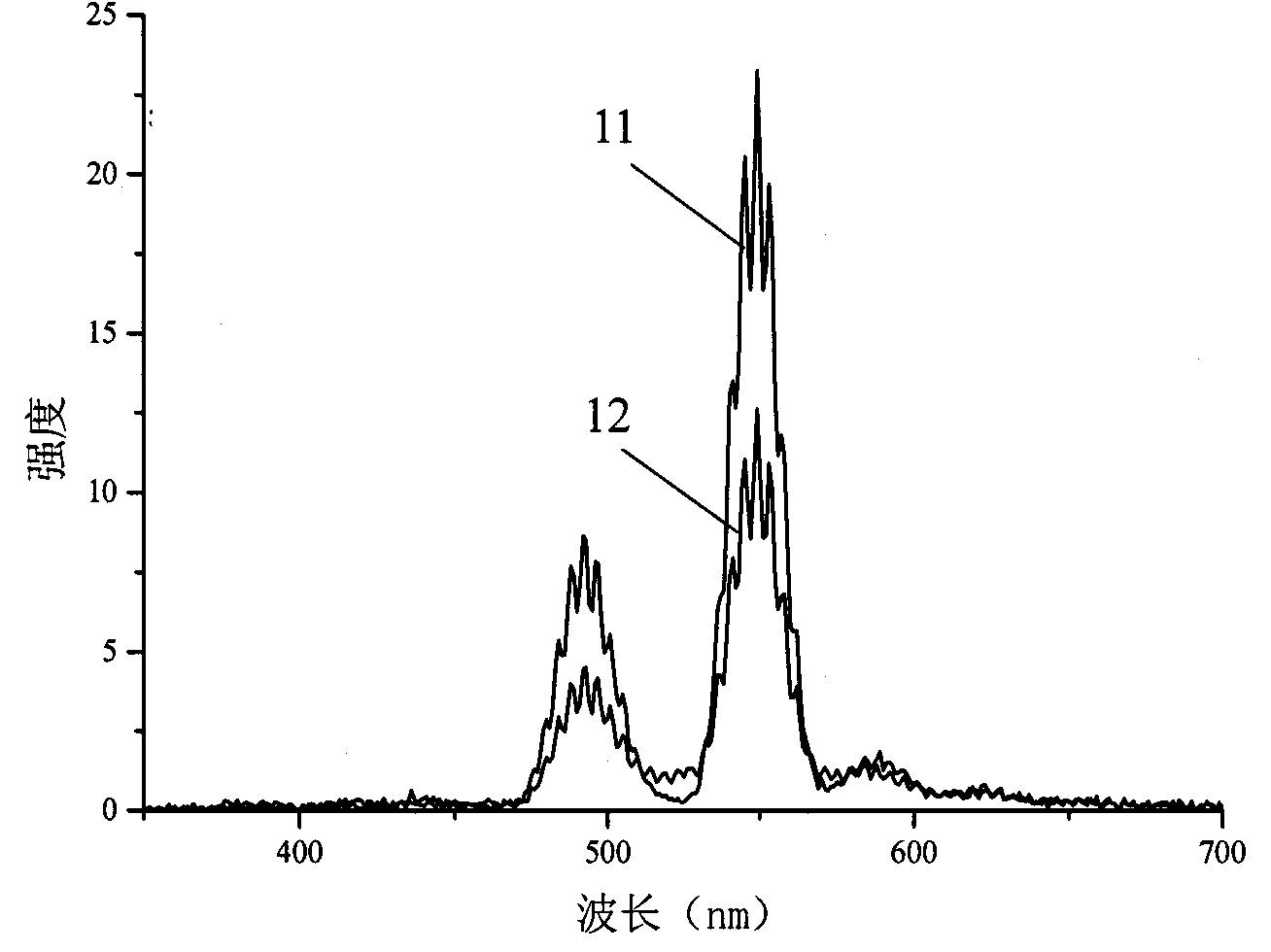

[0032] Using analytically pure Na 2 CO 3 , SiO 2 and 99.99% of Y 2 o 3 、Tm 2 o 3 、In 2 o 3 As the main raw material, weigh Na 2 CO 3 10.24g, Y 2 o 3 7.13g, SiO 2 11.62g, Tm 2 o 3 0.24g, then weigh the In 2 o 3 0.03g, mixed evenly and melted at 1400°C for 2 hours, poured out the molten glass frit, cooled to room temperature, placed in the air atmosphere of a low-temperature annealing furnace and raised to 700°C, held at this temperature for 5 hours, cooled and formed, and manufactured 30Na 2 O·9.8Y 2 o 360SiO2 2 0.2Tm 2 o 3 0.034In 2 o 3 (The coefficients in front of each component are mole fractions unless otherwise specified, the same below) Glass that emits blue light.

Embodiment 2

[0034] Using analytically pure Li 2 CO 3 , SiO 2 and 99.99% of Y 2 o 3 、Tm 2 o 3 , SnO 2 As the main raw material, weigh Li 2 CO 3 8.15g, Y 2 o 3 8.14g, SiO 2 13.27g, Tm 2 o 3 0.28g, then weigh the SnO which accounts for 0.1wt% of the total mass of the above raw materials 2 0.03g, mixed evenly and melted at 1350°C for 2 hours, poured out the molten glass frit, cooled to room temperature, placed in the air atmosphere of a low-temperature annealing furnace and raised the temperature to 600°C, held at this temperature for 8 hours, cooled and formed, and produced Get 30Li 2 O·9.8Y 2 o 3 60SiO2 2 0.2Tm 2 o 3 0.054SnO 2 Glass that emits blue light.

Embodiment 3

[0036] Using analytically pure K 2 CO 3 , SiO 2 and 99.99% of Y 2 o 3 、Tm 2 o 3 、In 2 o 3 As the main raw material, weigh K 2 CO 3 11.88g, Y 2 o 3 6.34g, SiO 2 10.33g, Tm 2 o 3 0.22g, then weigh 1wt% of the total mass of the above raw materials In 2 o 3 0.29g, mixed evenly and melted at 1450°C for 2h, poured out the molten glass frit, cooled to room temperature, placed in the air atmosphere of a low-temperature annealing furnace and raised to 800°C, heat-preserved and annealed at this temperature for 4h, cooled and formed, Get 30K 2 O·9.8Y 2 o 3 60SiO2 2 0.2Tm 2 o 3 0.368In 2 o 3 Glass that emits blue light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com