Method for producing ultrahigh molecular weight polyethylene

A technology of ultra-high molecular weight and production method, which is applied in the field of ultra-high molecular weight polyethylene production, and can solve problems such as difficult molecular weight operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

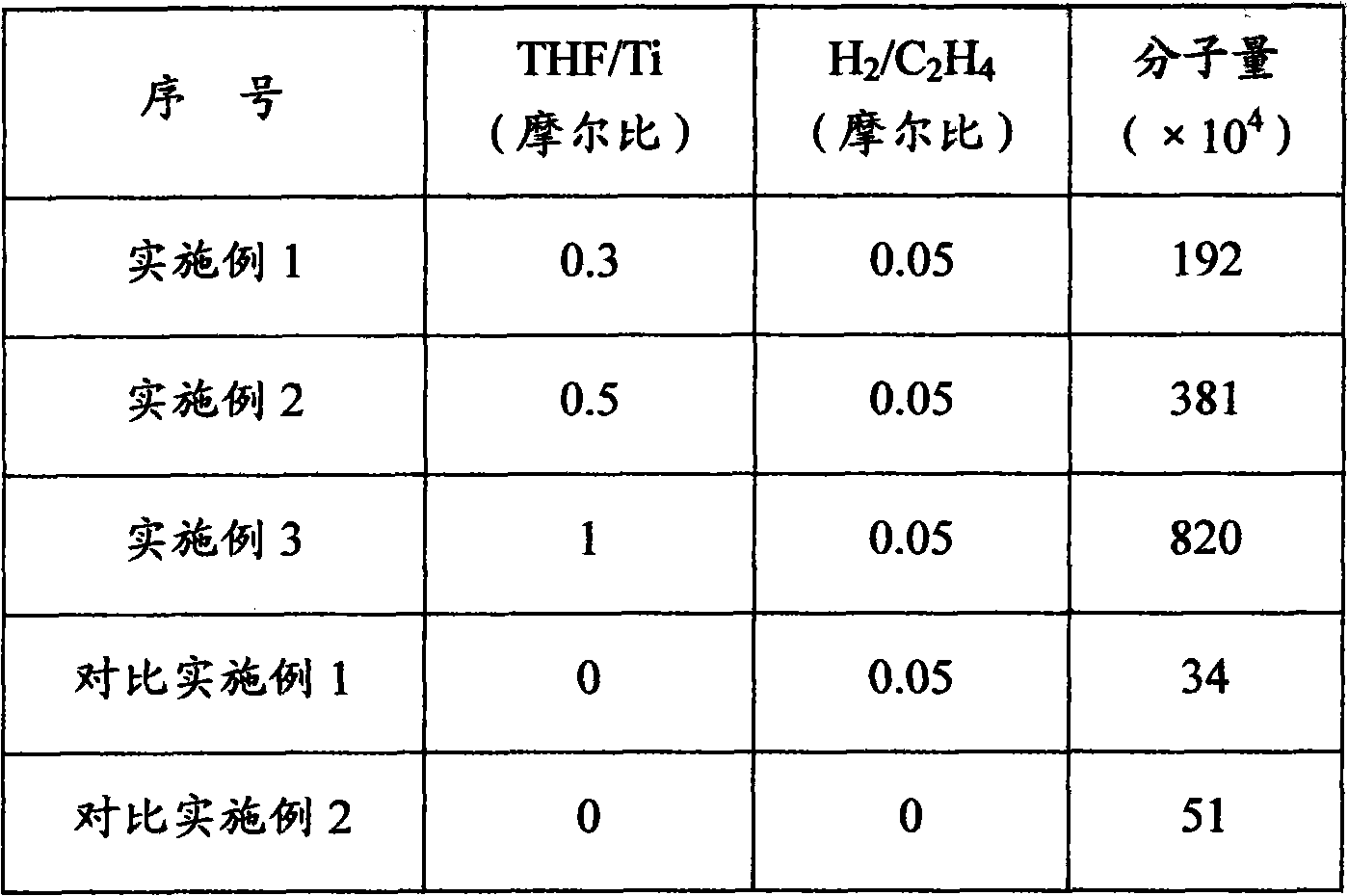

[0020] A 5L tank reactor is used, and the polymerization tank that has been dewatered and deoxygenated is filled with N 2 After purging for at least 3 times, inject 1.5L of hexane dried with molecular sieves and blown with nitrogen, add a certain amount of triethylaluminum and 20 mg of BCS01 catalyst, and 600 ml of hexene after deoxidation, dehydration, and purification, and tetrahydrofuran (THF), control THF / Ti=0.3 (molar ratio), and finally add 1.0L of hexane to flush the catalyst pipeline, then raise the temperature of the reactor, and add a sufficient amount of chain transfer agent H at one time when the temperature rises to 58°C 2 , control H 2 / C 2 h 4 =0.05 (molar ratio), then continuously add ethylene, the ethylene partial pressure is 1.0MPa, carry out constant pressure for 1 hour, the experimental results obtained are shown in Table 1.

Embodiment 2

[0022] Control THF / Ti=0.5 (molar ratio), other experimental procedures are the same as in Example 1, and the experimental results obtained are shown in Table 1.

Embodiment 3

[0024] Control THF / Ti=1 (molar ratio), other experimental steps are with embodiment 1, and the experimental result that obtains is shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com