Pipe made of high-strength and high-tenacity X90 thick wall seamless pipeline steel and manufacturing method thereof

A seamless pipeline, high toughness technology, used in manufacturing tools, temperature control, furnace types, etc., can solve the problems of difficult to guarantee the hardenability of thick-walled pipelines, inconsistent core structure and outer surface, poor welding performance, etc. , to achieve the effect of excellent low temperature impact performance, low carbon equivalent and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

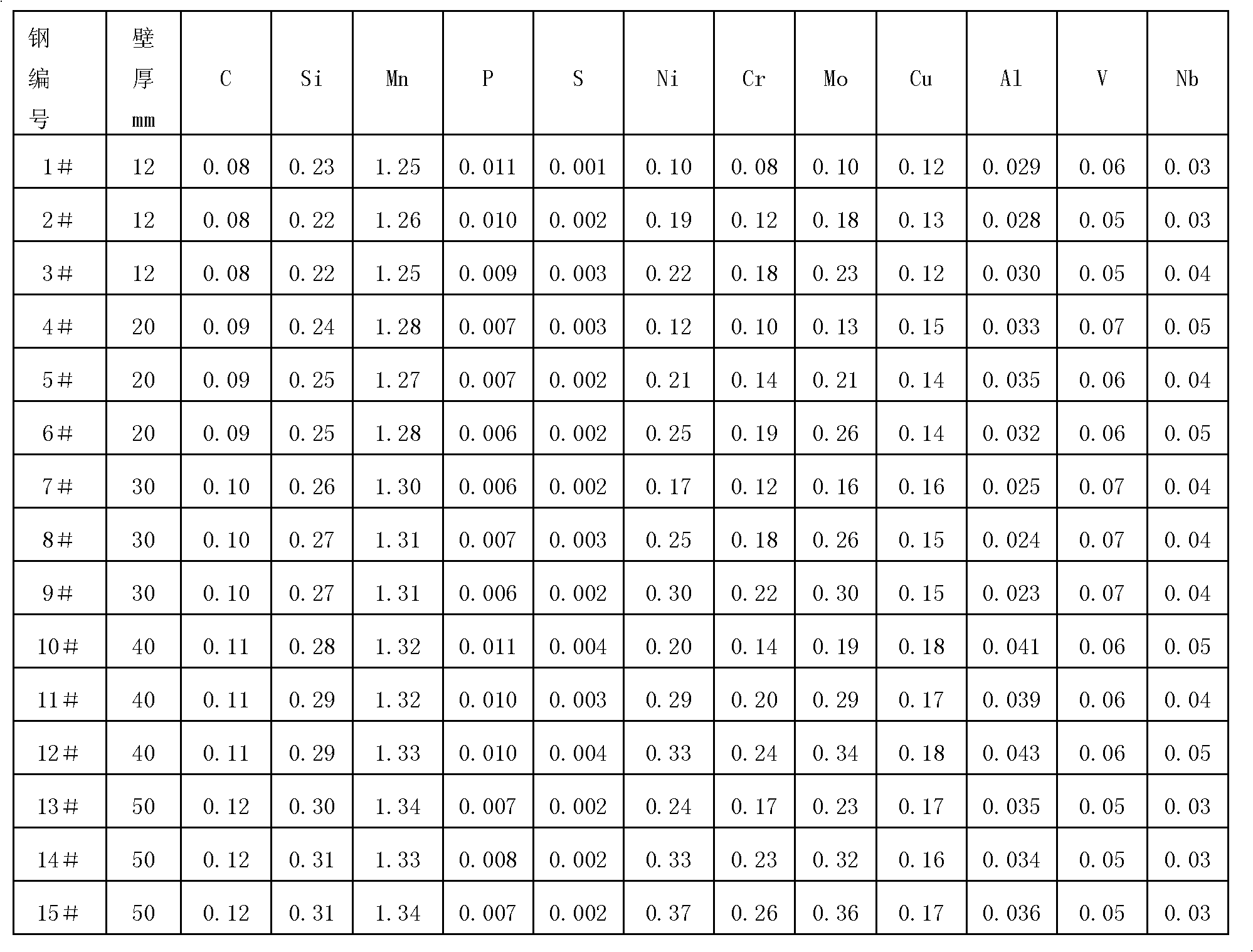

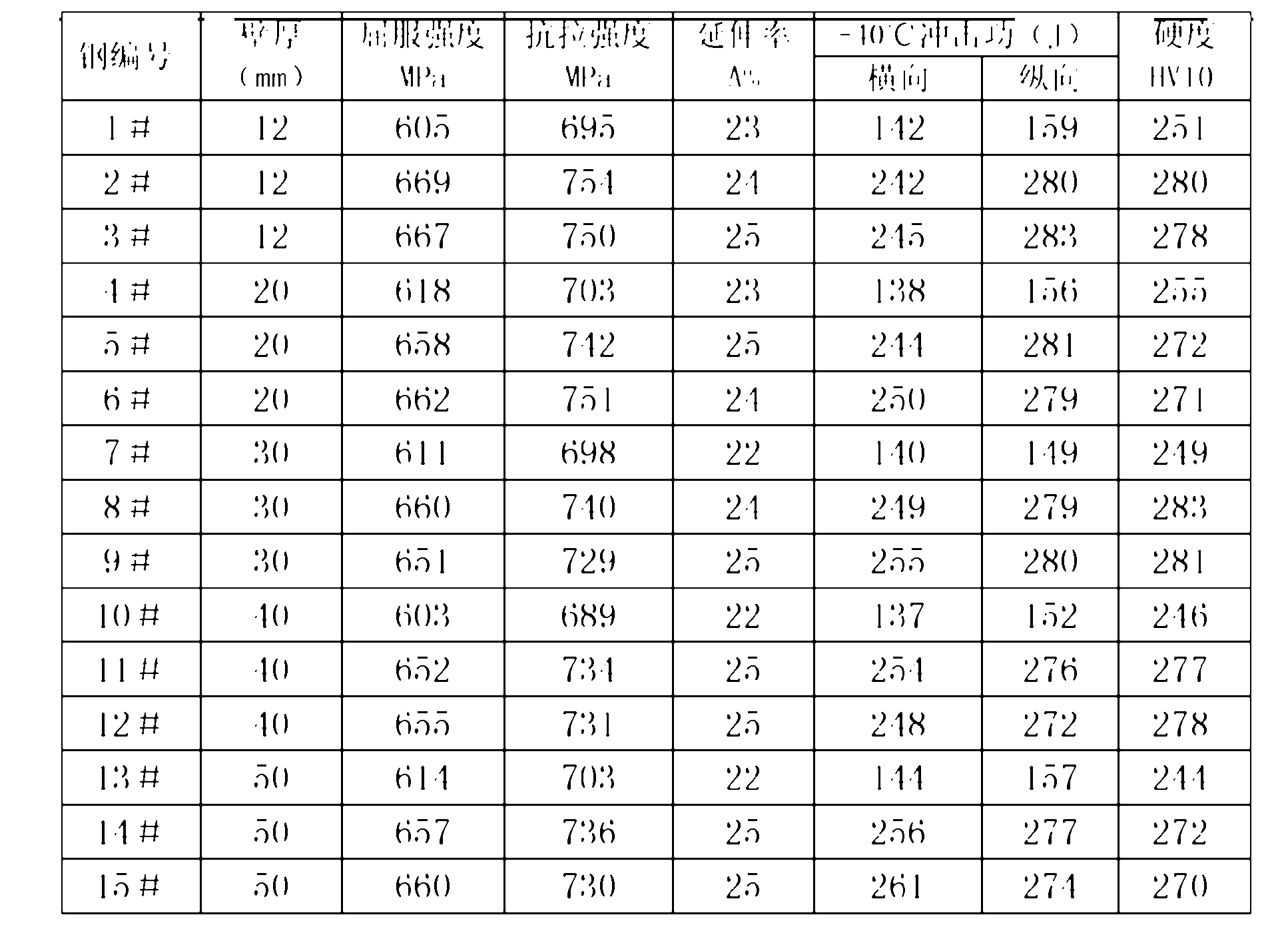

[0056] Adopt the inventive method to produce the actual alloy composition of the pipeline steel of different wall thicknesses as table 1:

[0057] Table 1 chemical composition

[0058]

[0059] In Table 1, the steel numbers from 1# to 15# are the actual chemical composition values of pipeline steels with different wall thicknesses. It can be seen that, except for Cr, Mo, and Ni elements, the contents of other alloy elements all meet the chemical composition range value required by the present invention.

[0060] In Table 1, steel numbers 1# to 3# are the chemical composition values of pipeline steels with a wall thickness of 12 mm, and the Cr, Mo, and Ni element contents of 2# steel are equal to the values calculated by the formula of Cr, Mo, and Ni contents in the present invention , the Cr of 1# steel, Mo, Ni element content are less than the formula calculation value of Cr, Mo, Ni content among the present invention, the Cr of 3# steel, Mo, Ni element content are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com