Method for designing and manufacturing PTT filament/staple single yarn composite yarn fabric

A composite yarn, single yarn technology, applied in the direction of dyeing method, fiber type, bleached products, etc., can solve the problems of inability to achieve elasticity, hand feel, and no obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

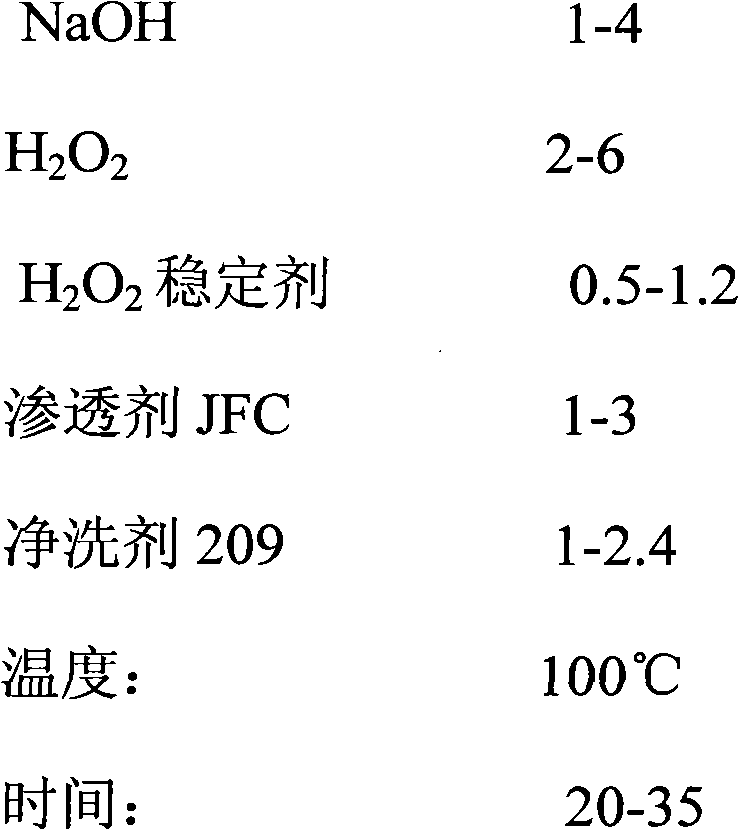

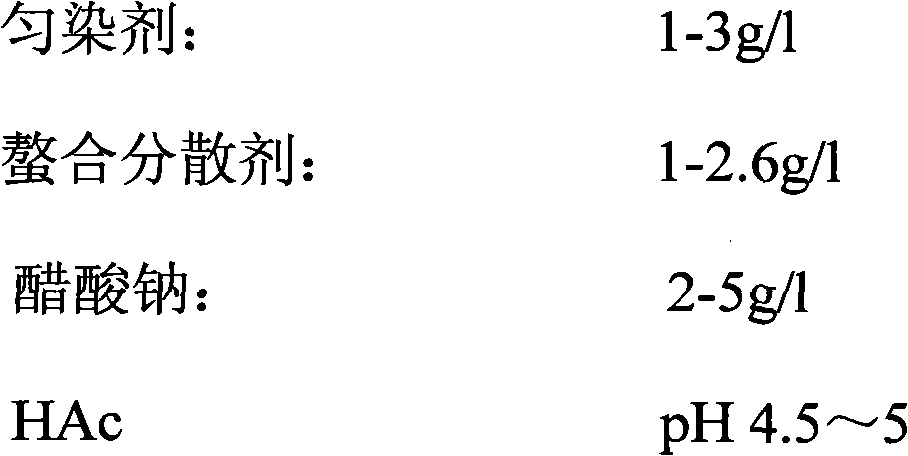

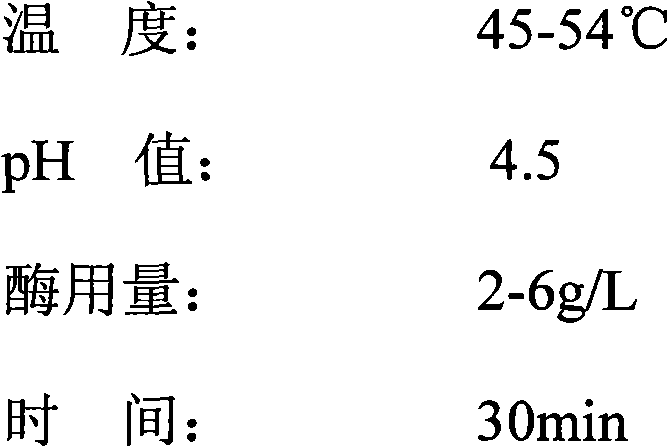

Method used

Image

Examples

Embodiment 1

[0033] Design and preparation method of a PTT filament / tencel staple fiber single yarn covered composite weft yarn fabric

[0034] Combination of raw materials: warp yarn: 9.8×2tex G100 tencel yarn, weft yarn: 83.3dtex PTT DTY filament and 9.8tex A100 / G100 (50 / 50) tencel single yarn hollow spindle coated composite yarn;

[0035] Weaving parameter design: Calculated according to the 22% wet heat shrinkage rate in the pre-scaling process, the warp density change is: the warp density of the upper machine is 402 threads / 10cm, the warp density of the lower machine is 410 threads / 10cm, and the warp density of the wet heat shrinkage is 525 threads / 10cm After stretching 4% heat setting, the warp density is 502 threads / 10cm; then the fabric width changes: the width of the upper machine is 183.5 cm, the lower machine is 180 cm, 140 cm after wet heat shrinkage, and 145.6 cm after stretching 4% heat setting.

[0036] Therefore, for finished fabrics that require a warp density of 500 threa...

Embodiment 2

[0073] Design and preparation method of a kind of PTT filament / mercerized cotton single yarn covered composite weft yarn fabric

[0074] Raw material combination:

[0075] Warp yarn 9.8×2tex G100 tencel yarn, weft yarn 83.3dtex PTT DTY filament and 9.8tex mercerized cotton single yarn hollow spindle covered composite yarn

[0076] Weaving parameter design: The finished product requires a fabric with a warp density of 500 threads / 10cm and a door width of 150cm. The weaving parameter design, pretreatment and heat setting processing parameters are controlled as follows: the warp density of the upper machine is 399 threads / 10cm, and the warp density of the lower machine is 407 Roots / 10cm, the warp density is 525 strands / 10cm after the wet heat shrinkage rate is 23%, and the warp density is 500 strands / 10cm after stretching 4% heat setting; the fabric width changes: the width of the upper machine is 189cm, and the width of the lower machine is 185cm , The door width is 144cm after...

Embodiment 3

[0108] Design and preparation method of a PTT filament / tencel staple fiber single yarn network composite weft yarn fabric

[0109] Combination of raw materials: warp yarn: 9.8×2tex G100 Tencel yarn, weft yarn: 83.3dtex PTT DTY filament and 9.8texA100 / G100 (50 / 50) Tencel single yarn network composite yarn;

[0110] Weaving parameter design: For finished fabrics that require a warp density of 500 threads / 10cm and a door width of 150cm, the weaving parameter design, pretreatment and heat setting processing parameters are controlled as follows: the warp density of the upper machine is 400 threads / 10cm, and the warp density of the lower machine is 400 threads / 10cm. 408 threads / 10cm, the warp density is 530 threads / 10cm after the wet heat shrinkage rate is 20%, and the warp density is 502 threads / 10cm after stretching 3.8% heat setting; the fabric width changes: the upper machine width is 190cm, the lower machine width 186cm, the door width is 145cm after 22% damp heat shrinkage, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com