HMA/CC (Hot-Mix Asphalt)/(Cement Concrete) composite type pavement structure and constructing method thereof

A composite pavement and construction method technology, applied in the field of rigid-flexible composite pavement structure, can solve the problem of lack of in-depth and detailed research on rigid-flexible pavement, and achieve the effects of improving discomfort, delaying reflection cracks, and improving waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

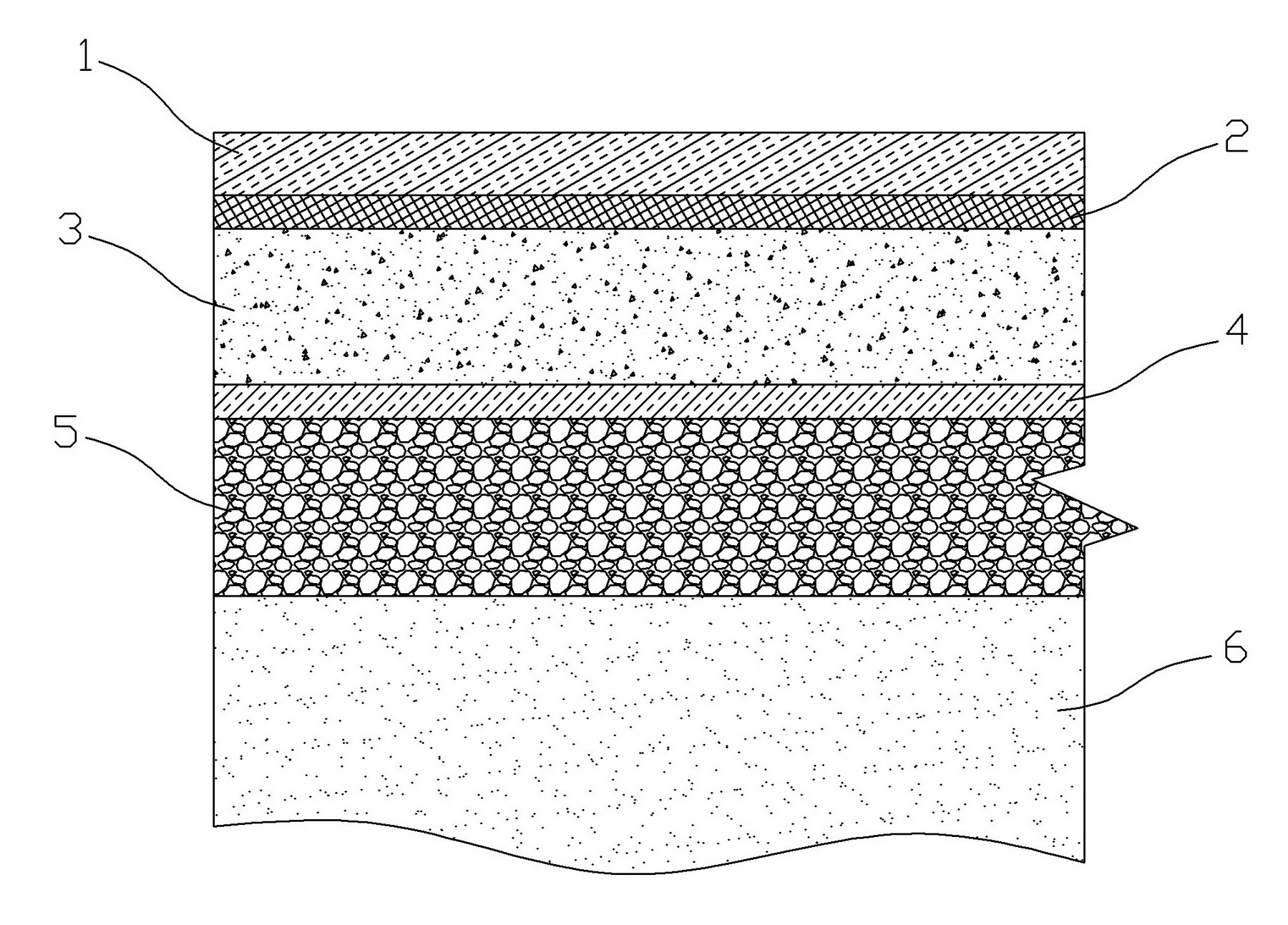

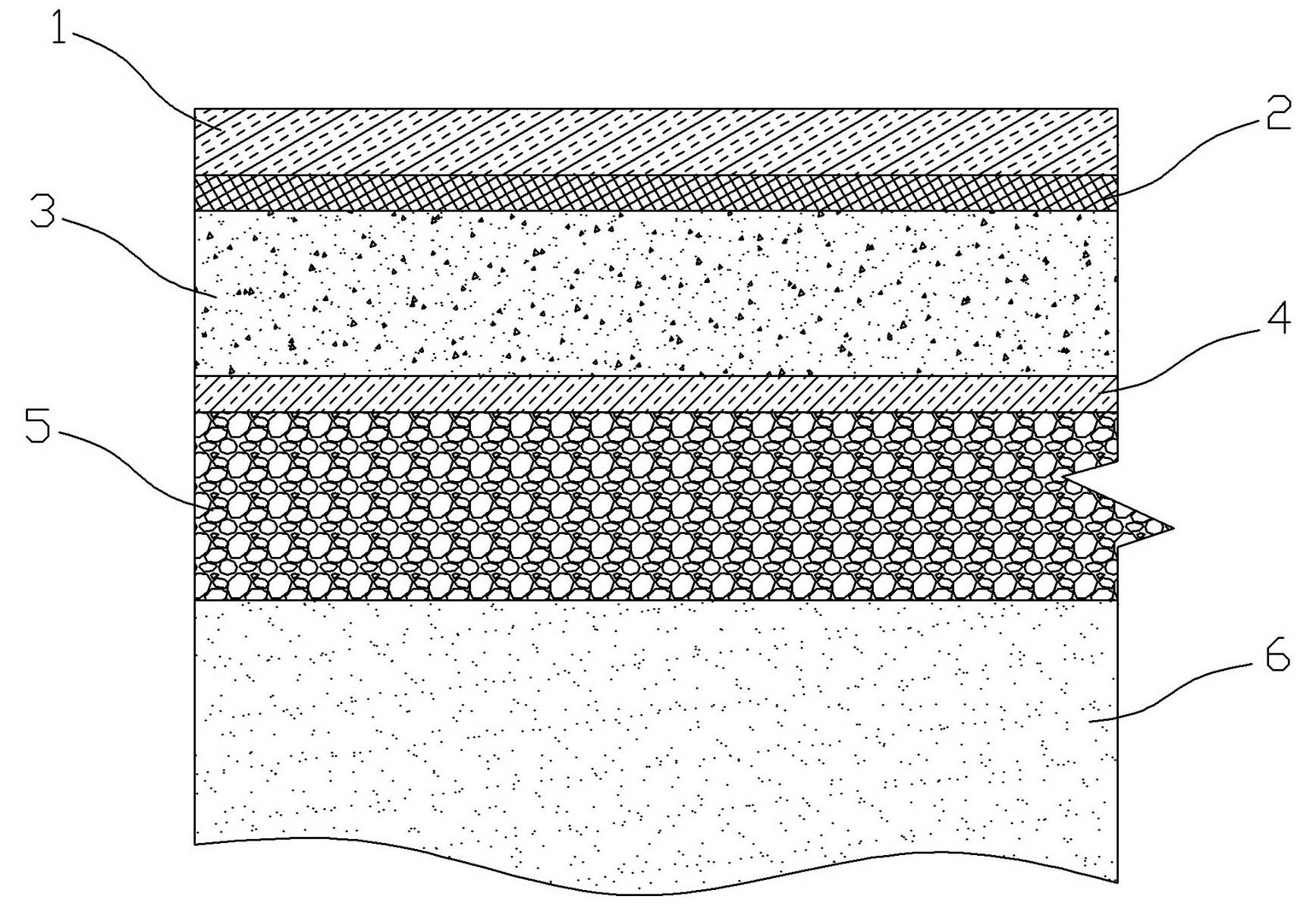

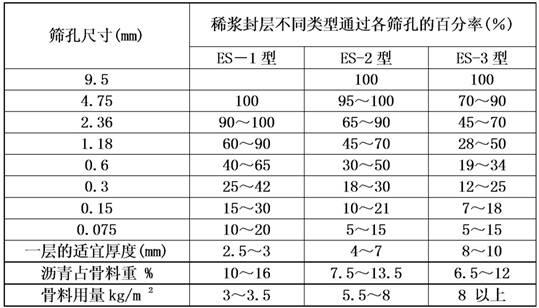

[0031] Example 1 An HMA / CC composite pavement structure, including a road base 5, on which an emulsified asphalt slurry seal layer SS (0.8-1.2 cm) 4, a cement concrete slab CC (22 ~26cm) 3. Reinforcement layer 2, hot mix asphalt layer HMA (4~8cm) 1; the reinforcement layer 1 is a geotextile layer.

[0032] The construction method of the above-mentioned HMA / CC composite pavement structure:

[0033] (1) Laying of road base 5: Before building the road base, implement corresponding treatment measures on the soft soil section; road base 5 should have sufficient strength, rigidity and water stability to provide continuous and uniform support for the road surface, and the top surface should also be Flat, with the same transverse slope as the surface layer to ensure uniform thickness of the surface layer. Compared with the base layer of asphalt concrete pavement as the main stress layer, the strength and stiffness requirements of cement concrete pavement can be reduced, but water stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com