Upwind cone-shaped full air curtain split type injection range hood

A range hood, cone-shaped technology, applied in the field of household kitchen range hoods, can solve the problems of increased power and noise, inconvenient cleaning of oil stains, high operating noise, etc., to achieve easy cleaning, good smoke exhaust effect, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

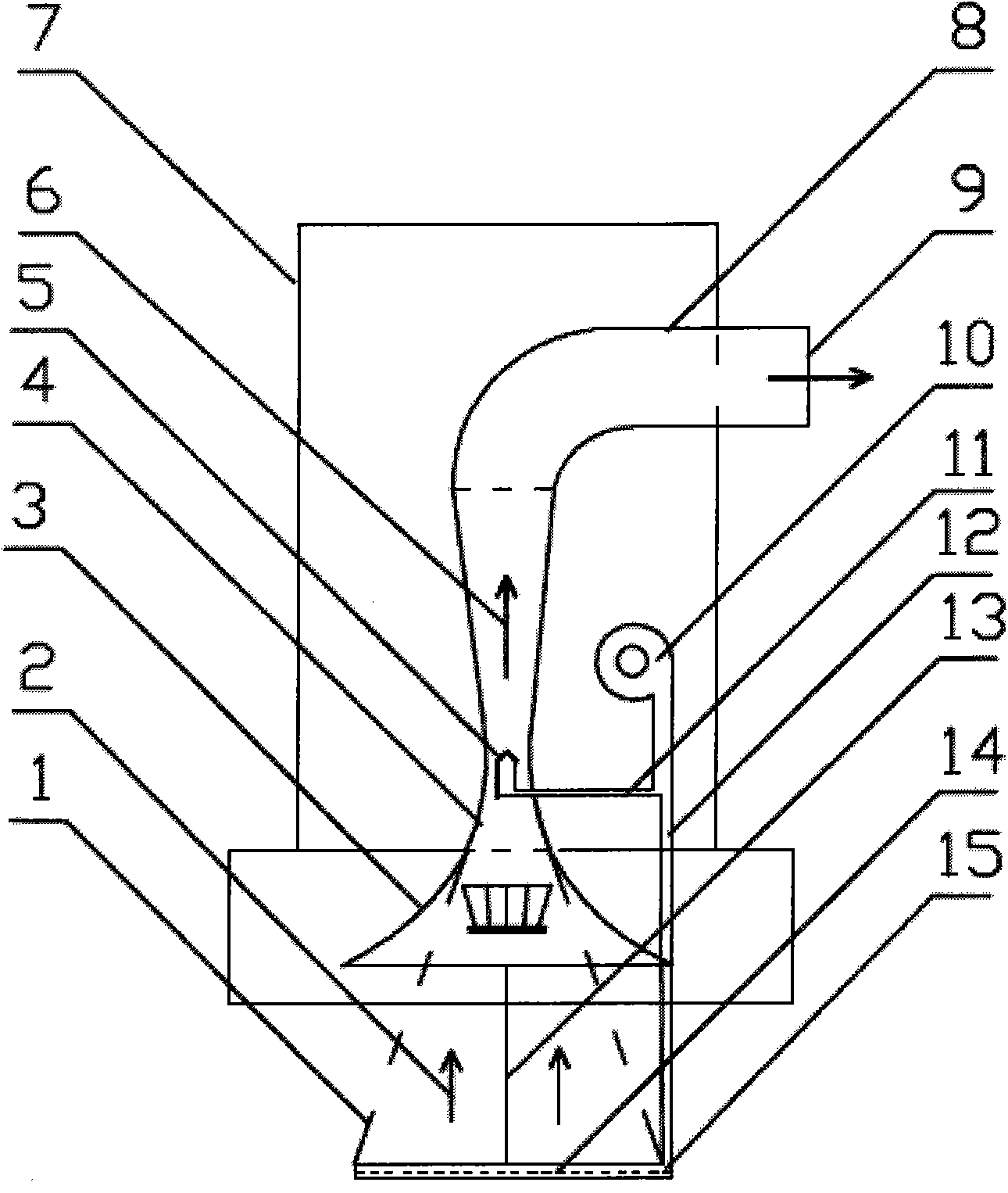

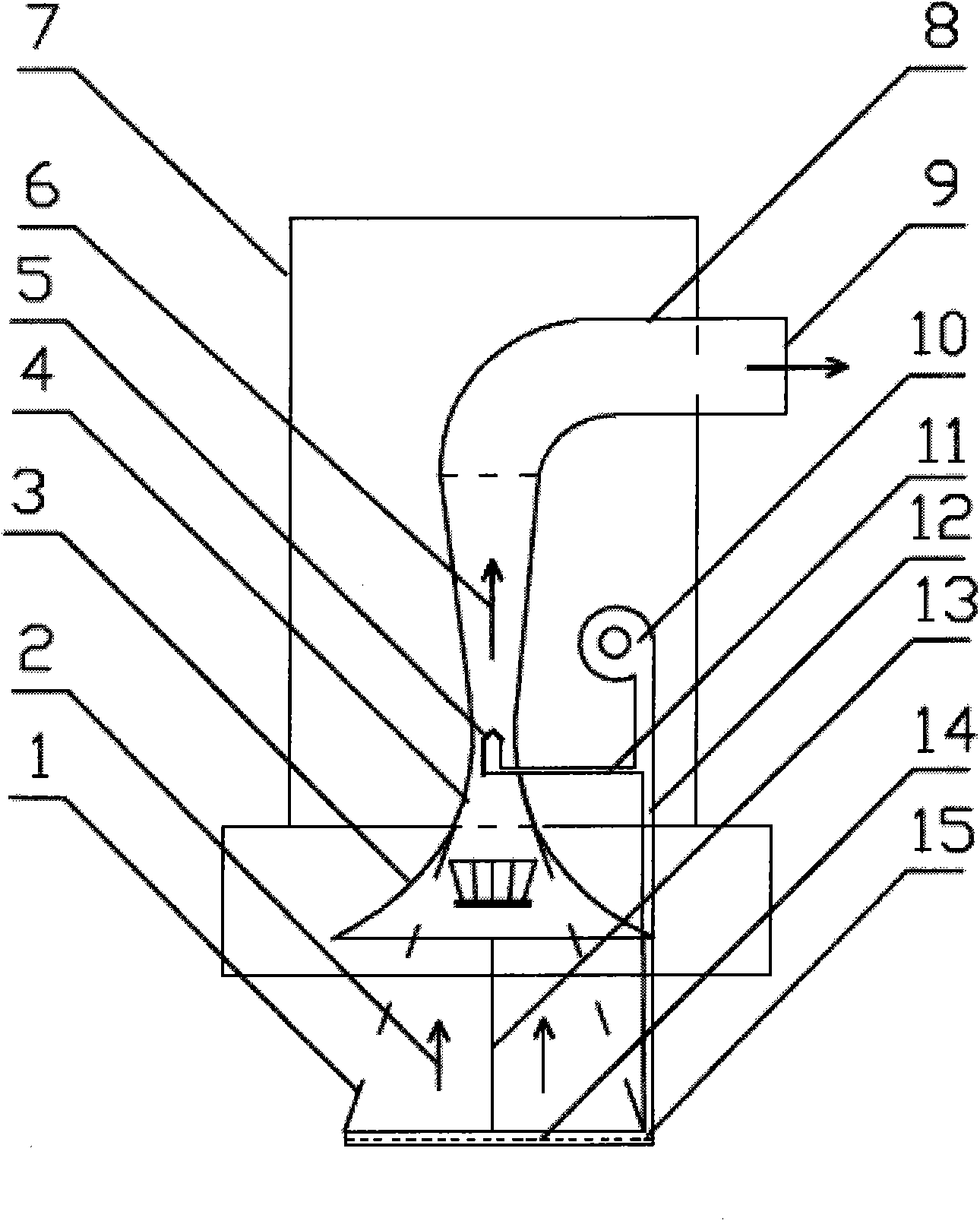

[0012] The annular blast pipe 15 whose diameter is larger than the caliber of the wok and the air outlet 14 has a certain inclination angle is placed slightly lower than the mouth of the wok through three supporting hooks 13 evenly distributed on the circumference, and is connected to the fan 10 through the lower connecting air pipe 12 . Range hood shell 7 is built-in oil collection hood assembly 3 and zoom pipe 4 and oil fume discharge pipe 8 that are successively connected with it, zoom pipe 4 throat place installs air spray nozzle 5, links to each other with blower fan 10 through upper connecting air pipe 11. When the fan 10 is working, a part of the air flow is ejected from the series of inclined air outlets 14 on the annular air injection pipe 15 to form a conical air curtain 1, which enters the zoom pipe 4 under the guidance of the oil collection fume hood assembly 3 and flows at a high speed at the throat Negative pressure is formed; another part of the airflow is eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com