Method for positioning low impedance tiny flaws in comb metal wire structure

A metal wire, low-impedance technology, applied in the field of failure analysis and positioning, can solve the problem of not finding defects, achieve fast positioning, high efficiency, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Such as Figure 6 The illustrated invention comprises the following steps:

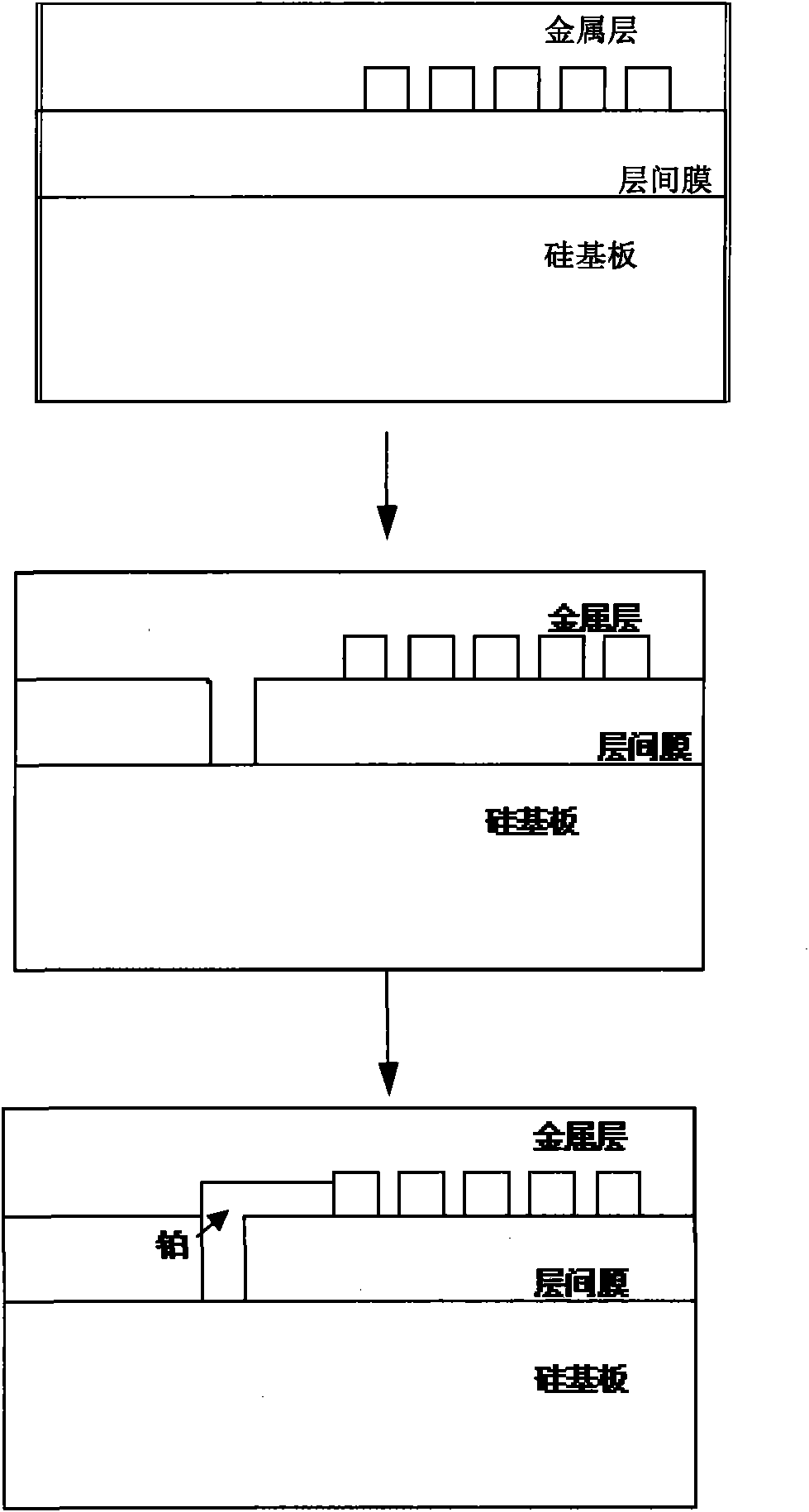

[0017] Step 1. If figure 1 As shown, the focused particle beam electron microscope FIB is used to perforate the silicon substrate (the silicon substrate is usually the ground terminal), and the platinum-plated metal layer of the focused particle beam electron microscope FIB is used to connect one end of the comb line to the substrate to achieve grounding.

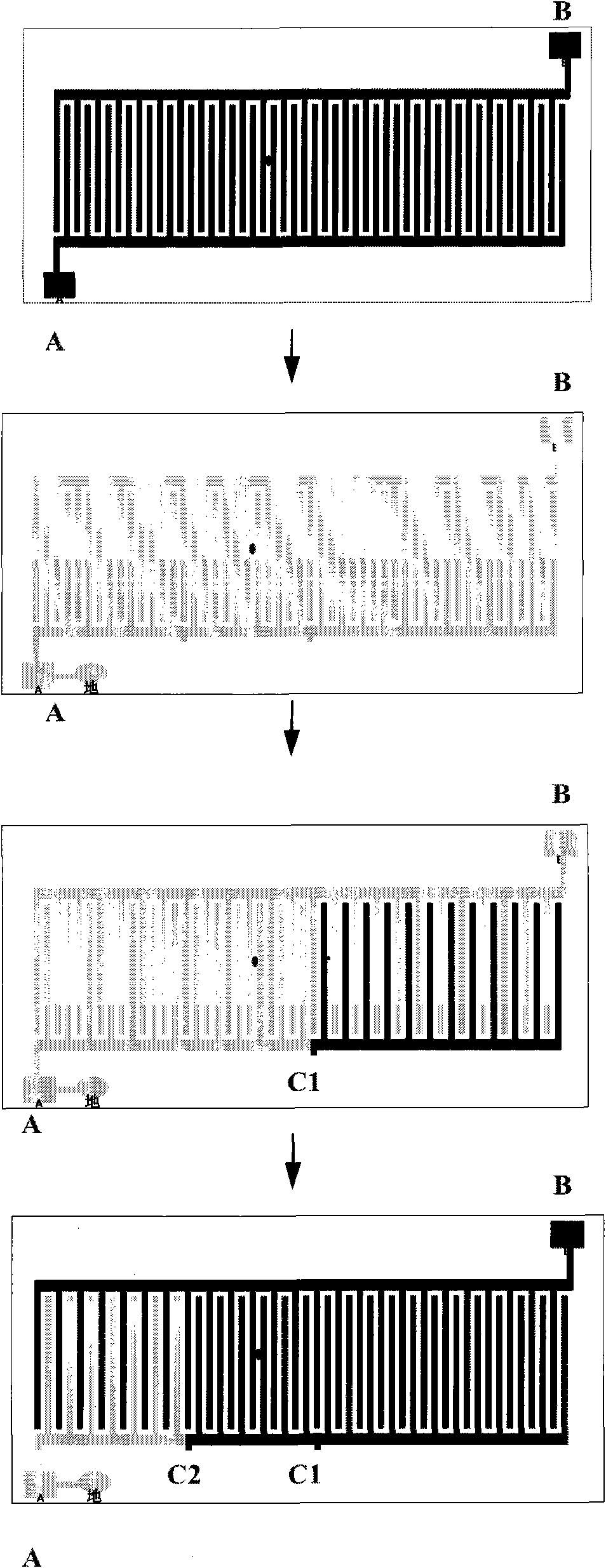

[0018] Step 2. If figure 2 As shown, the comb line is divided into n times, and each time is divided into a voltage contrast VC inspection, and each time the voltage contrast VC can locate the defect within half of the original area, n times After equal division, the defect will be located within the area range of 1 / 2 to the nth power.

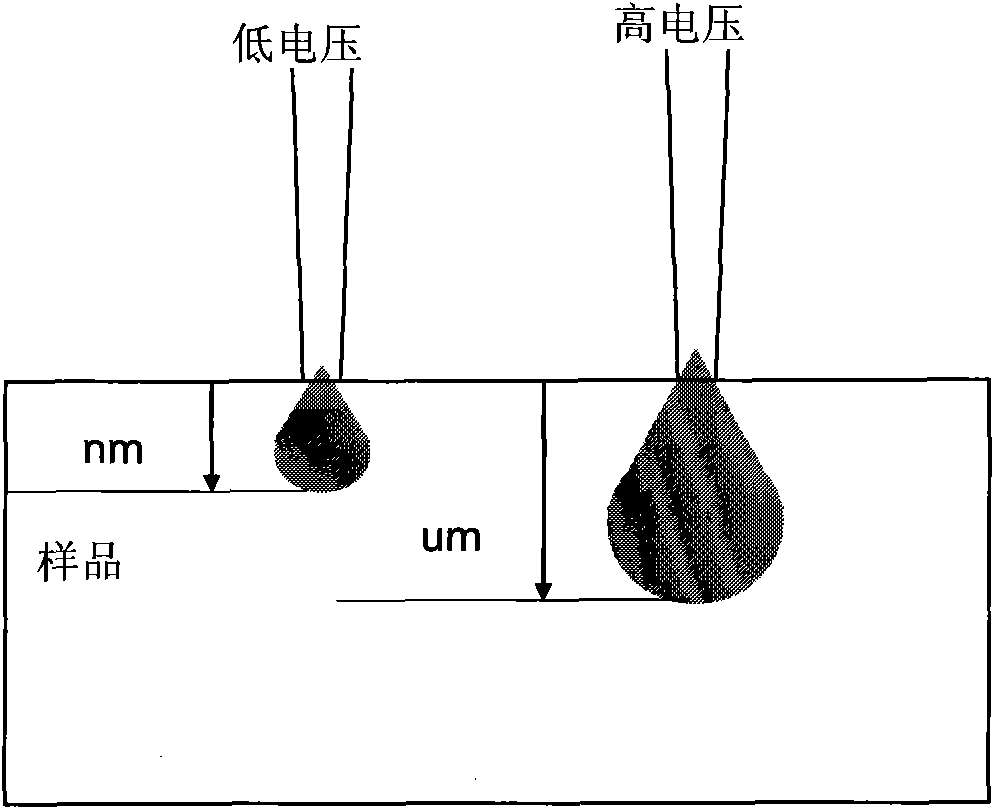

[0019] Step 3. If image 3 As shown, in the small area positioned, the defects buried by the insulating film can be observed by scanning the scanning electron microscope SEM with a high accelerating vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com