Method and system for optimal design and process control of heat setting process of elastic fabric

An elastic fabric and process optimization technology, applied in the field of heat setting process control, can solve the lack of elastic fabric heat setting process mechanism and model research, complex problems, etc., to achieve intelligent optimal control, reduce scrap rate, and overcome inaccurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

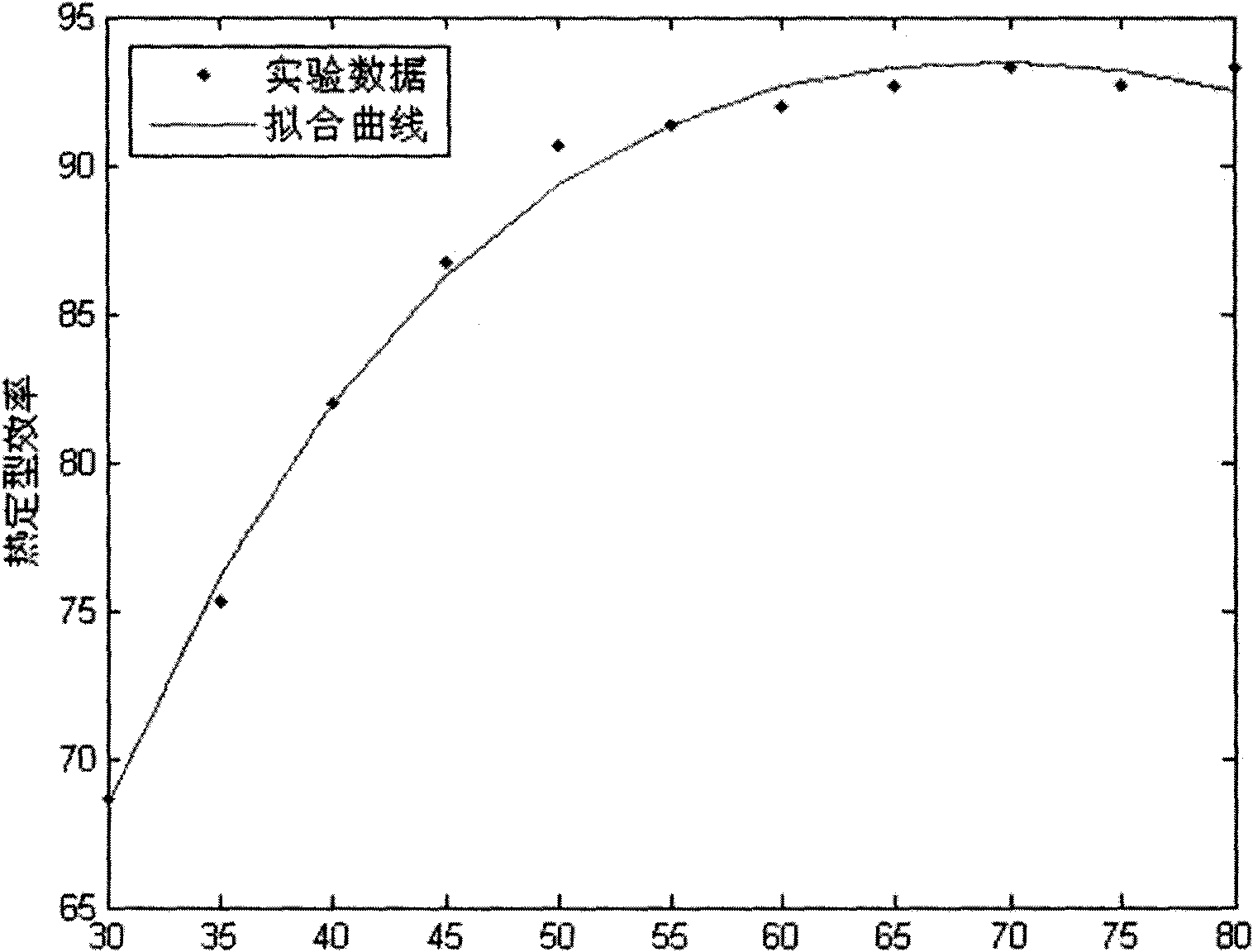

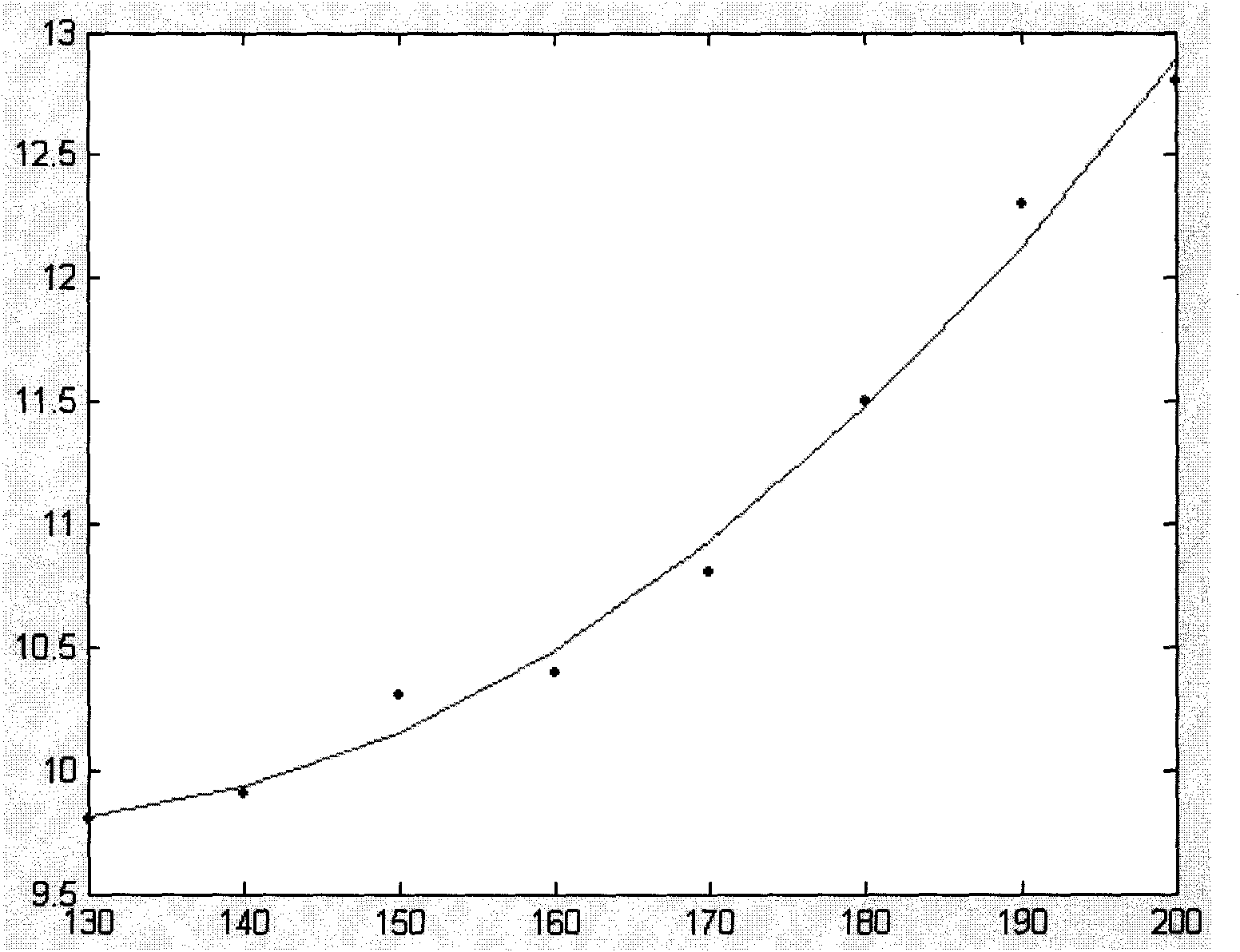

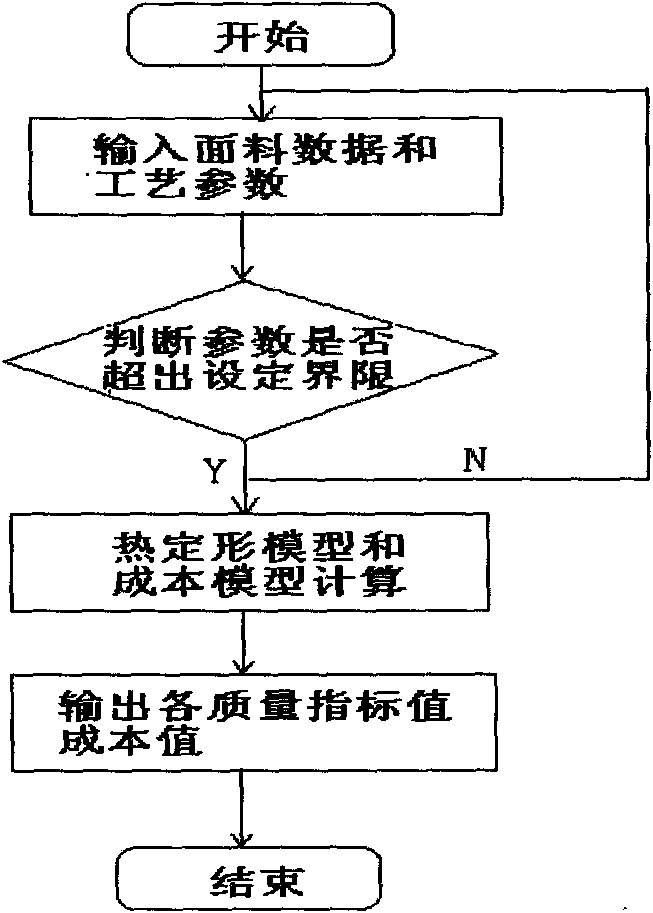

[0035] Taking elastic fabrics containing spandex as an example, through in-depth analysis of the heat setting mechanism of elastic fabrics, and on the basis of a large number of heat setting experiments, a heat setting process model for elastic fabrics containing spandex is constructed to provide a The method and system for optimal design of the heat setting process of spandex elastic fabric further realize the intelligent optimization control of the heat setting machine, thereby improving the yield and production efficiency of the production process, and reducing the scrap rate and heat setting energy consumption. Of course, the present invention is not limited thereto, and the following methods are also applicable to other types of elastic fabrics.

[0036] 1. Principle of heat setting of elastic fabric containing spandex

[0037] Based on the analysis of the characteristics of spandex fibers, it can be seen that since the size of the soft segment phase in spandex fibers is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com