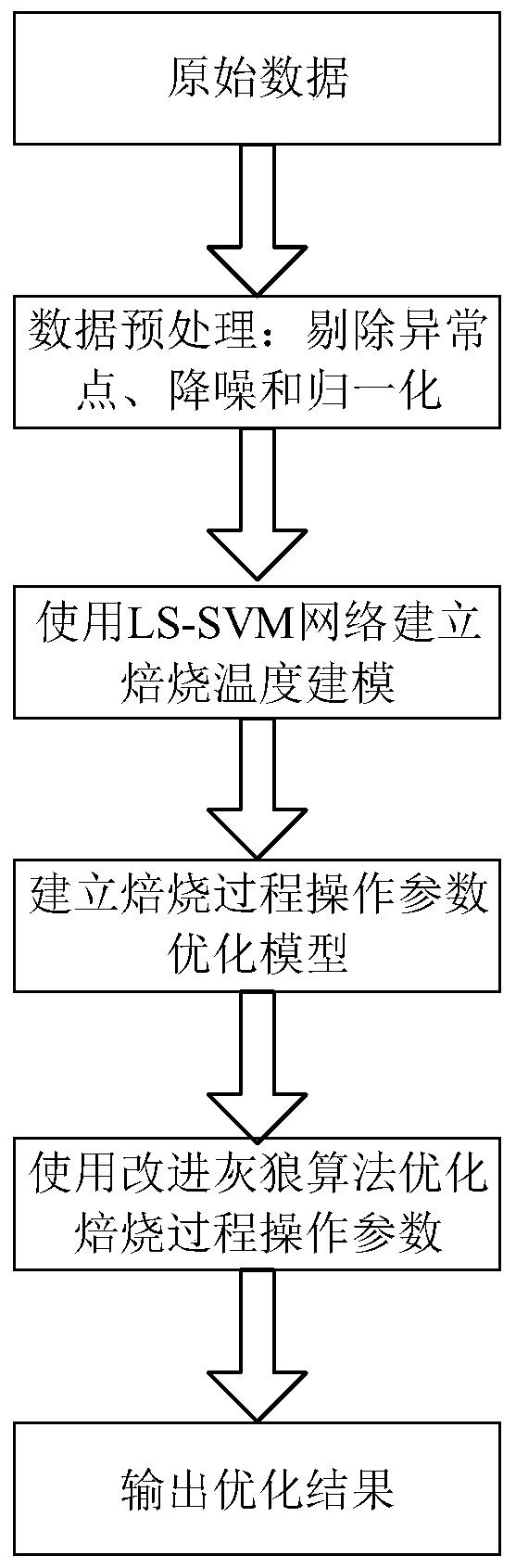

Operating parameter optimizing method for alumina calcination process

A technology of operating parameters and optimization methods, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve problems such as modeling and optimization of alumina roasting temperature, achieve stable roasting production process, reduce fluctuations, reduce The effect of production energy consumption and heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

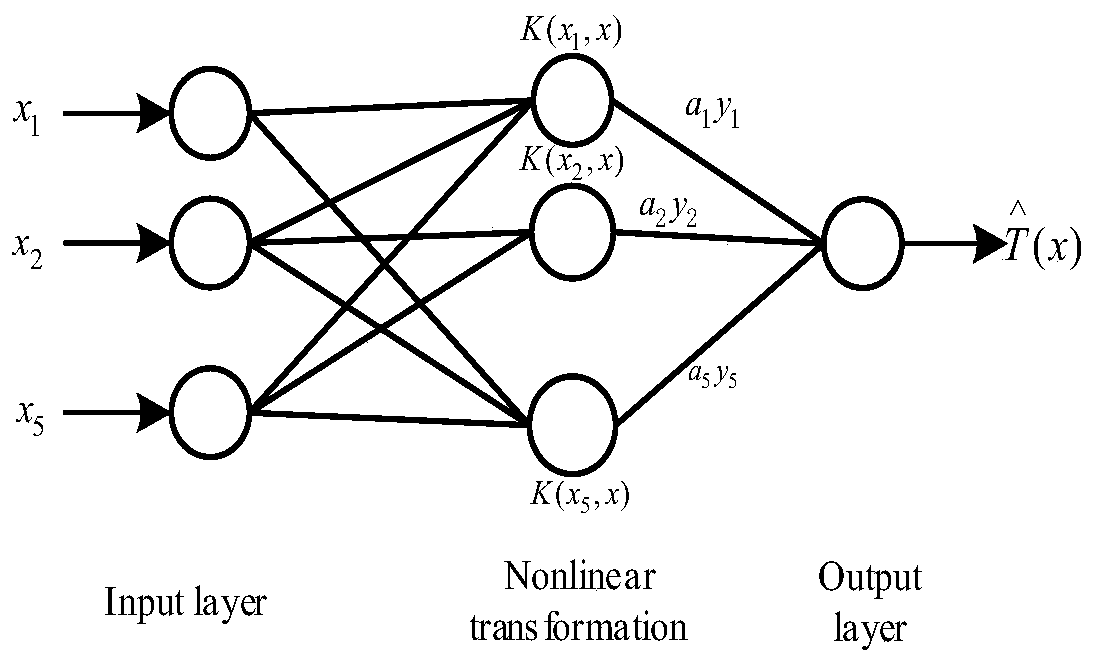

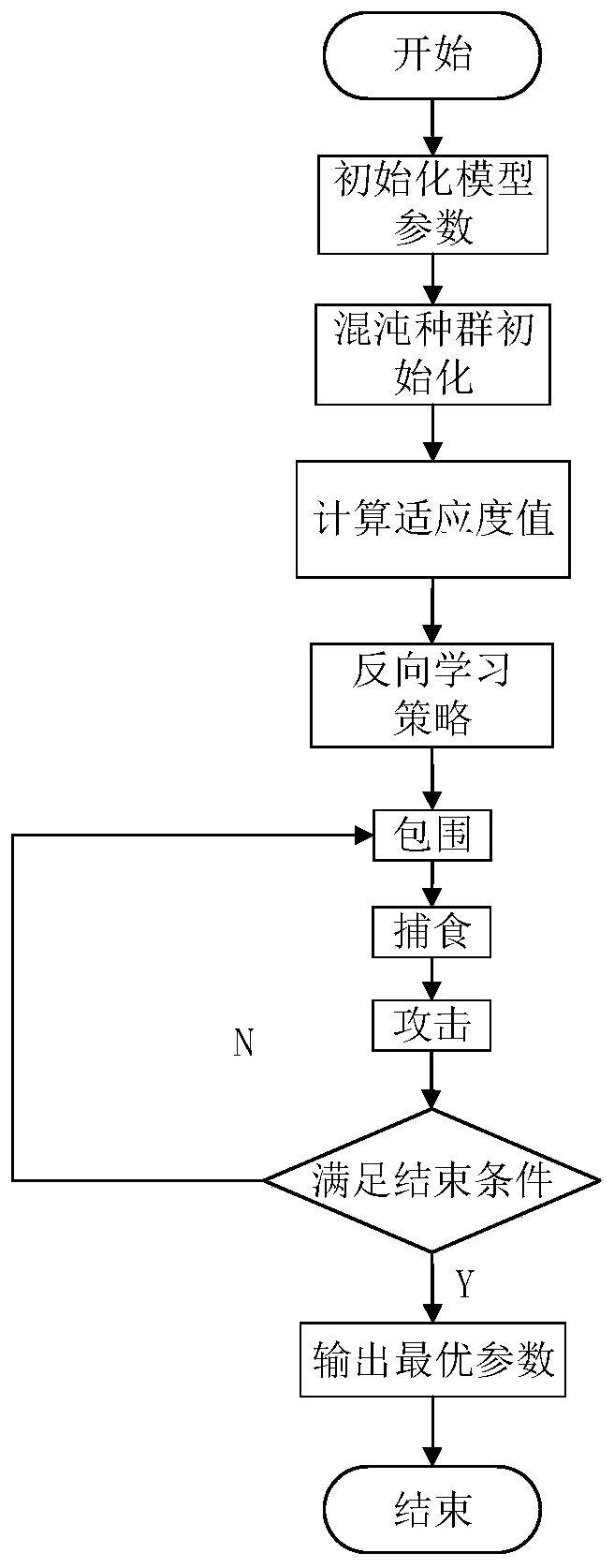

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

[0035] Roasting temperature is the main parameter reflecting the state of alumina production during the roasting process, and the key factor affecting product quality; too high temperature will cause low ignition loss, large system heat dissipation loss, increased energy consumption, too low temperature, and material combustion Insufficient and cannot meet the production requirements.

[0036] The process parameters of the alumina roasting workshop are tested every 2 hours, and there is a serious lag, which causes fluctuations in the roasting temperature and affects production quality. In order to realize the optimal control of the roasting process, it is necessary to establish a predictive model of the roasting temperature for real-time monitoring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com