Method for enabling smoke detection and alarm system to be used in phosphine environment

An alarm system, phosphine technology, applied in the direction of alarms, fire alarms, scattering characteristics measurement, etc., can solve the problem of unusable fire detection alarms, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

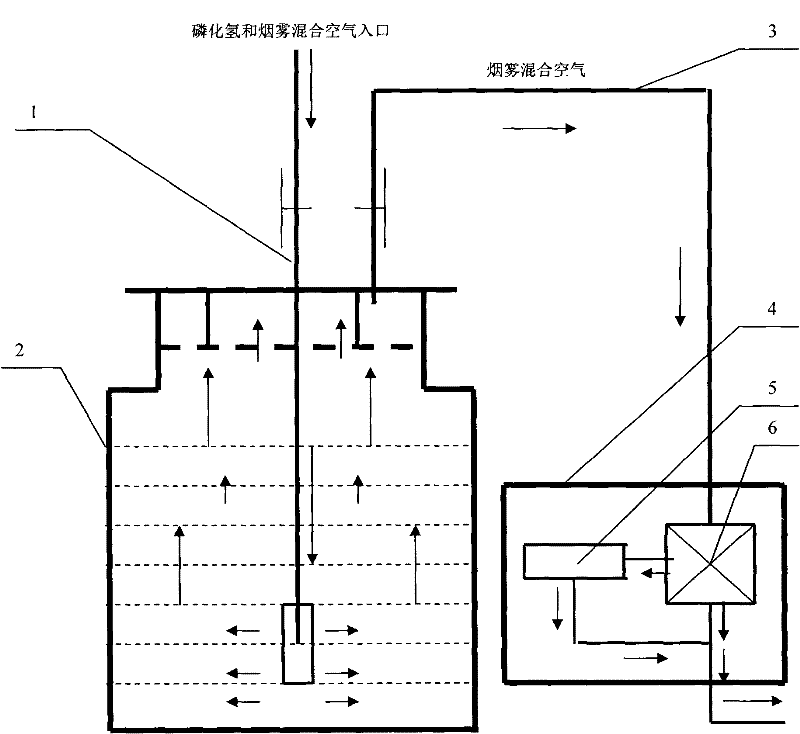

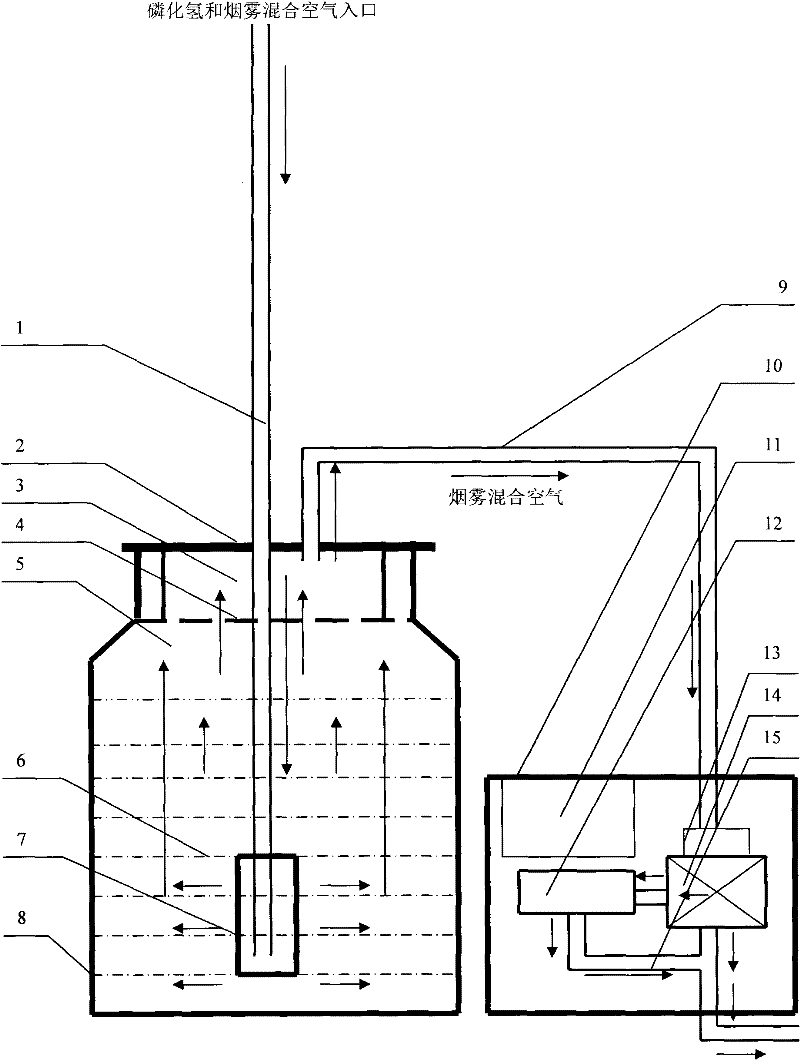

Method used

Image

Examples

Embodiment 1

[0050] When carrying out aluminum phosphide fumigation to kill insects, with (1) Pd2+ and Fe3+ ion concentration is the Pd(II)-Fe(III) liquid-phase catalytic oxidant of 0.114mol / L; (2) calcium hypochlorite efficient bleaching powder saturated solution 1600ml are added together into a negative pressure reaction separator with a height of 460mm and a diameter of 168mm. The operation is as follows:

[0051] (1) Close the sealing cover tightly, subject to no air leakage;

[0052] (2) Put a pot of smoldering sawdust in the warehouse where aluminum phosphide is fumigated to kill insects;

[0053] (3) Connect the UPCV sampling tube of the air sampling type high-sensitivity smoke detection and alarm system to the warehouse and the negative pressure reaction separator that are being fumigated and killed by aluminum phosphide, and pay attention to close the intake valve of the intake pipe first ;

[0054] (4) Connect the negative pressure reaction separator and the air sampling type ...

Embodiment 2

[0064] After aluminum phosphide fumigating insecticide is finished, with (1) Pd2+ and Fe3+ ion concentration is the Pd(II)-Fe(III) liquid-phase catalytic oxidant of 0.114mol / L; (2) calcium hypochlorite efficient bleaching powder saturated solution 1600ml Add together to a negative pressure reaction separator with a height of 460mm and a diameter of 168mm. The operation is as follows:

[0065] (1) Close the sealing cover tightly, subject to no air leakage;

[0066] (2) Put a pot of smoldering sawdust in the warehouse where aluminum phosphide is fumigated to kill insects;

[0067] (3) Connect the UPCV sampling tube of the air sampling type high-sensitivity smoke detection and alarm system to the warehouse and the negative pressure reaction separator that are being fumigated and killed by aluminum phosphide, and pay attention to close the intake valve of the intake pipe first ;

[0068] (4) Connect the negative pressure reaction separator and the air sampling type high-sensiti...

Embodiment 3

[0078] When aluminum phosphide fumigation is in progress, 1300ml of calcium hypochlorite high-efficiency bleaching powder saturated solution is added to a negative pressure reaction separator with a height of 460mm and a diameter of 168mm. The operation is as follows:

[0079] (1) Close the sealing cover tightly, subject to no air leakage;

[0080] (2) Put a pot of smoldering sawdust in the warehouse where aluminum phosphide is fumigated to kill insects;

[0081] (3) Connect the UPCV sampling tube of the air sampling type high-sensitivity smoke detection and alarm system to the warehouse and the negative pressure reaction separator that are being fumigated and killed by aluminum phosphide, and pay attention to close the intake valve of the intake pipe first ;

[0082] (4) Connect the negative pressure reaction separator and the air sampling type high-sensitivity smoke detection and alarm system with the UPCV sampling tube;

[0083] (5) Open the intake valve of the intake ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com