Method for preparing magnetic core mesoporous hollow carbon spheres by vacuum nano pouring

A technology of mesoporous hollow spheres and hollow carbon spheres, applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., to achieve simple operation, convenient control, and intuitive and large effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

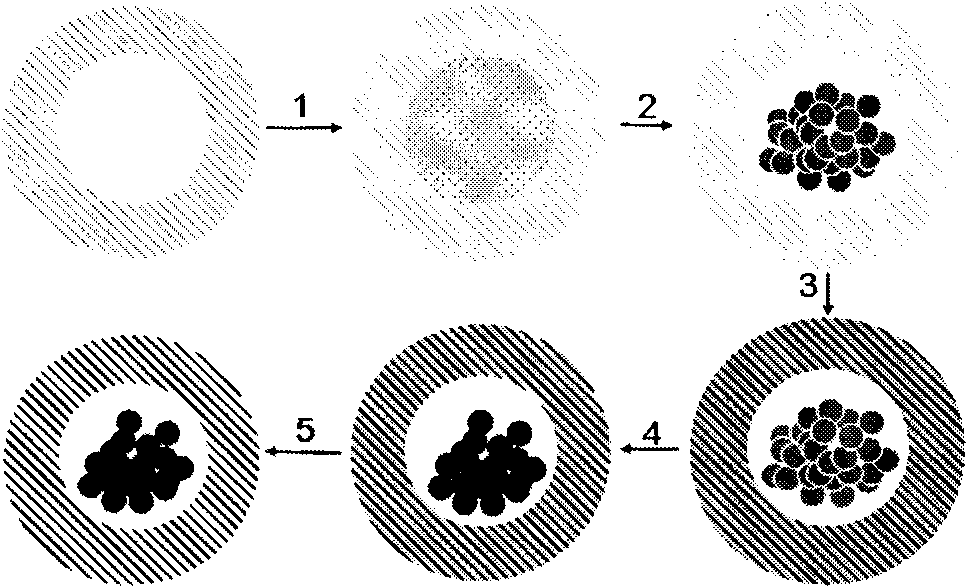

Method used

Image

Examples

Embodiment 1

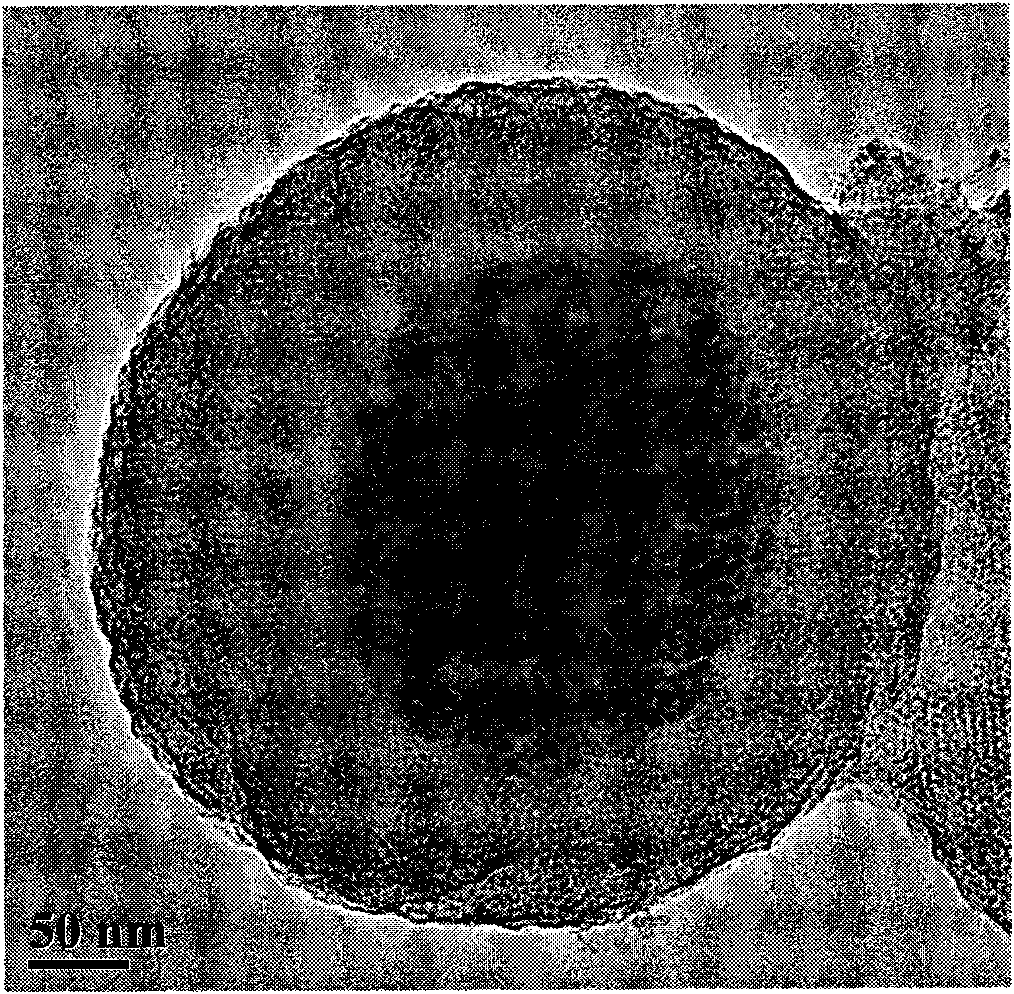

[0029] According to literature reports, aluminum-containing cubic phase mesoporous hollow silica spheres were prepared. Prepare 25 mL of 0.5 M ferric nitrate solution in a beaker with hydrated ferric nitrate, then add 1.0 g of mesoporous hollow spheres, and stir with a glass rod for 1 minute to form a cloudy solution. Put the beaker with ferric nitrate turbid solution into the vacuum box, and vacuumize (10 -1 Pa), and maintain the vacuum condition for 5 minutes. Then open the vacuum valve and adjust the vacuum box to atmospheric pressure. Stay in this state for 5 minutes. Then take out the beaker and suck out the ferric nitrate solution, leaving the hollow ball precipitate that has been injected with the ferric nitrate solution in the bottle. The beaker containing the precipitate was dried at normal pressure below 80 °C, and then washed three times with 99.7% absolute ethanol. Afterwards, dry at normal pressure below 80°C. The dried hollow spheres were put into a crucible...

Embodiment 2

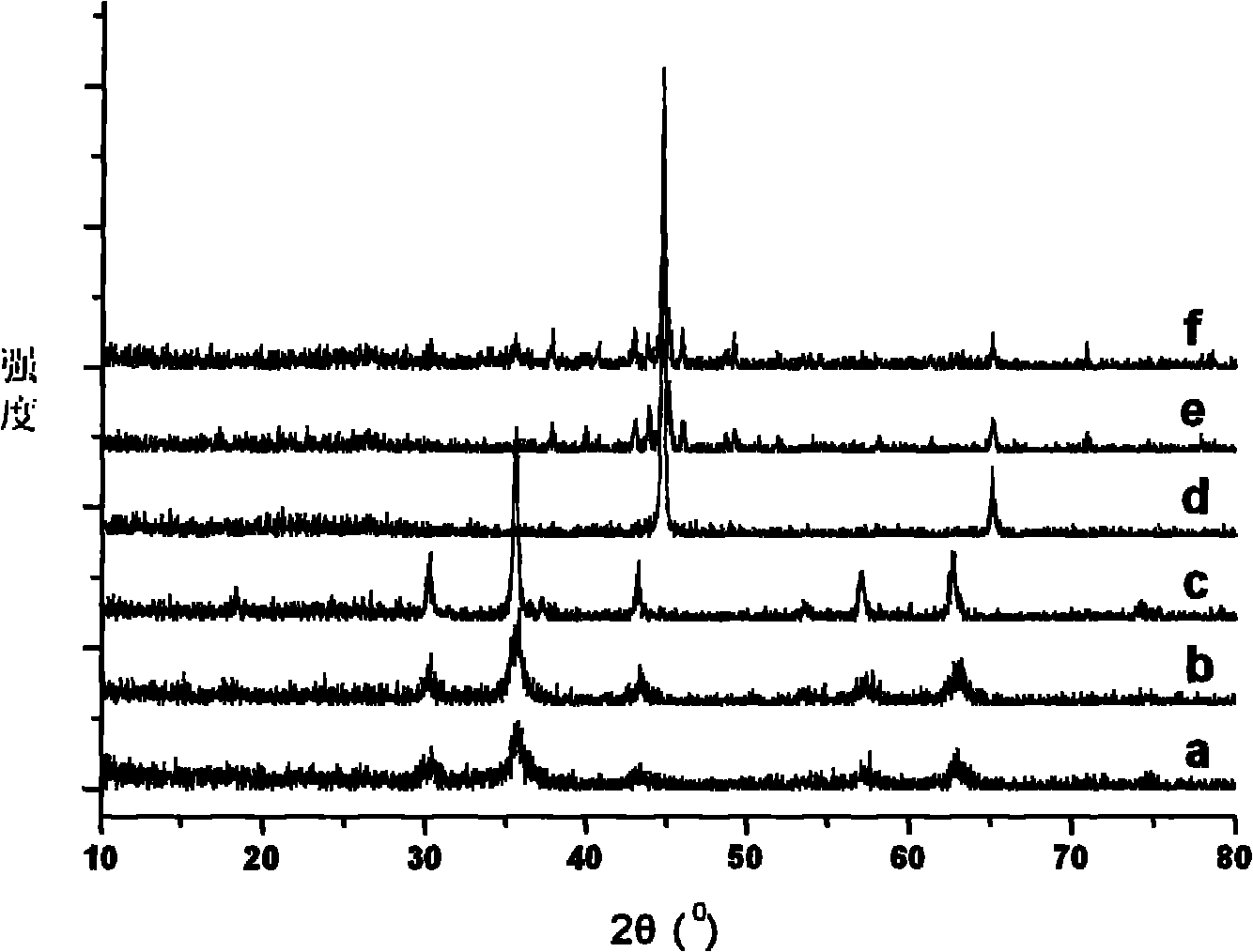

[0031] Described according to technological process (with embodiment example 1), adopt the ferric nitrate ethanolic solution of 0.25M, can make the ferric nitrate that contains a certain amount 2 o 3 Nuclear mesoporous hollow spheres. After subsequent addition of carbon source and heat treatment, magnetic Fe can be obtained 3 o 4 Mesoporous hollow carbon spheres with nuclei ( image 3 a), the magnetic size is 7.8emu / g. The obtained magnetic mesoporous hollow carbon spheres have a mesoporous size of 2.32 nm and a pore volume of 0.46 cm 3 g -1 , the specific surface area is 772.7m 2 g -1 .

Embodiment 3

[0033] Described according to technological process (with embodiment example 1), adopt the ferric nitrate ethanolic solution of 1.0M, can make the ferric nitrate that contains a certain amount 2 o 3 Nuclear mesoporous hollow spheres. After the subsequent addition of carbon source and heat treatment, magnetic Fe can be obtained 3 o 4 Mesoporous hollow spheres with nuclei ( image 3 c), the magnetic size is 45.1emu / g. The obtained magnetic mesoporous hollow carbon spheres have a mesoporous size of 2.32 nm and a pore volume of 0.20 cm 3 g -1 , the specific surface area is 338.9m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com