Method for applying photoresist lifting-off technology to protect photoetching alignment marks

A technology of photolithography alignment and stripping process, which is applied in the direction of photolithography, optics, and optomechanical equipment on the pattern surface, and can solve the problems affecting the shape of the front-layer lithography alignment marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

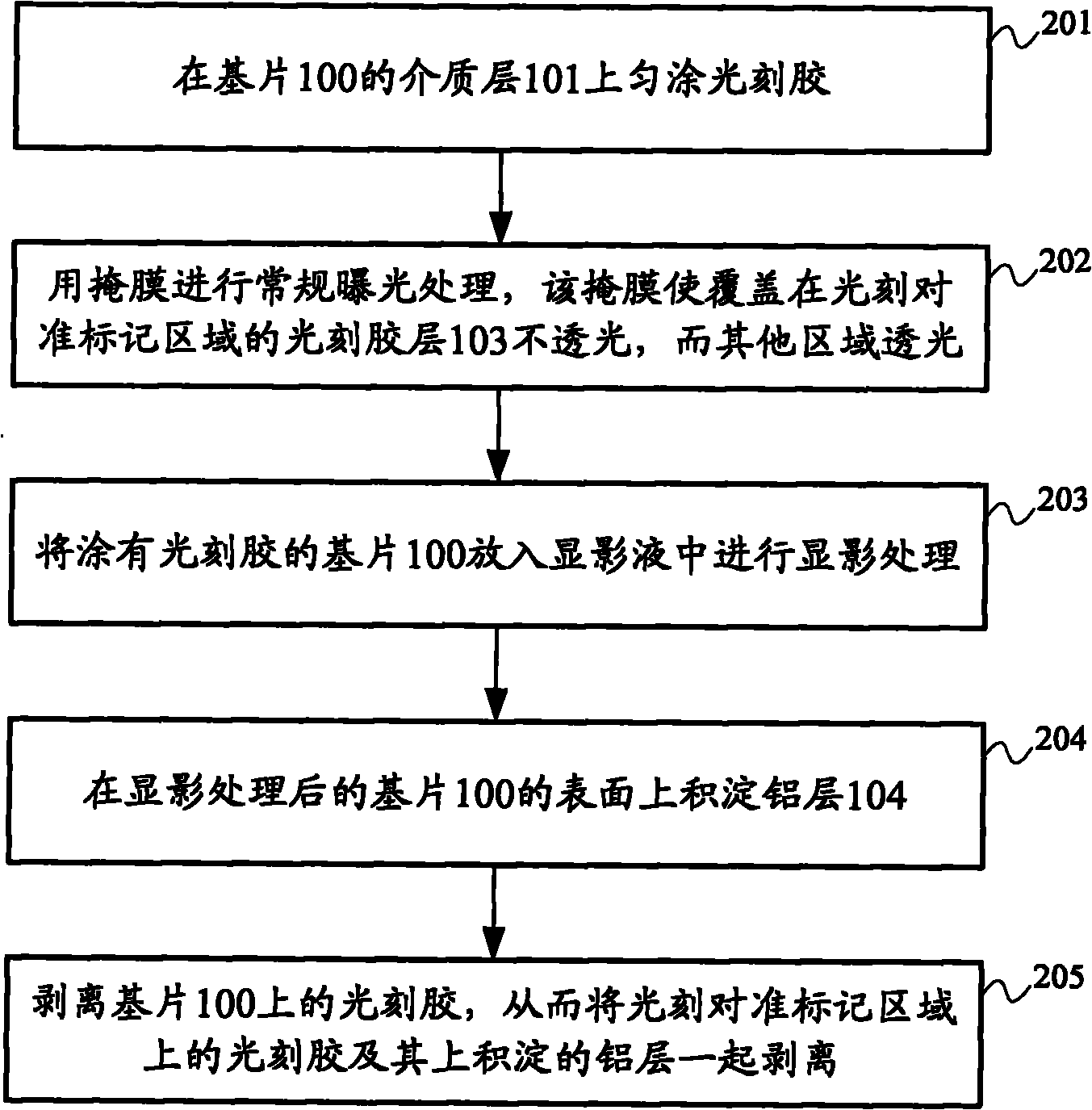

[0016] In view of the above-mentioned problems existing in the prior art, the embodiments of the present invention protect the photolithographic alignment marks on the front layer before covering the metal layer by applying the photoresist stripping process, so that the photolithographic alignment marks are not covered by the metal layer , so as to maintain the shape of the photolithography alignment mark, so that the photolithography machine can be aligned according to the alignment mark in the subsequent photolithography process.

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] still as in Figure 1a The substrate covered with an aluminum layer is shown as an example. When the uppermost dielectric layer of the substrate 100 needs to be covered with an aluminum layer, the embodiment of the present invention applies a photolithographic lift-off process to protect the photolithographic alignme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com