Activated carbon for controlling gas components

A technology of activated carbon and natural gas, applied in the field of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

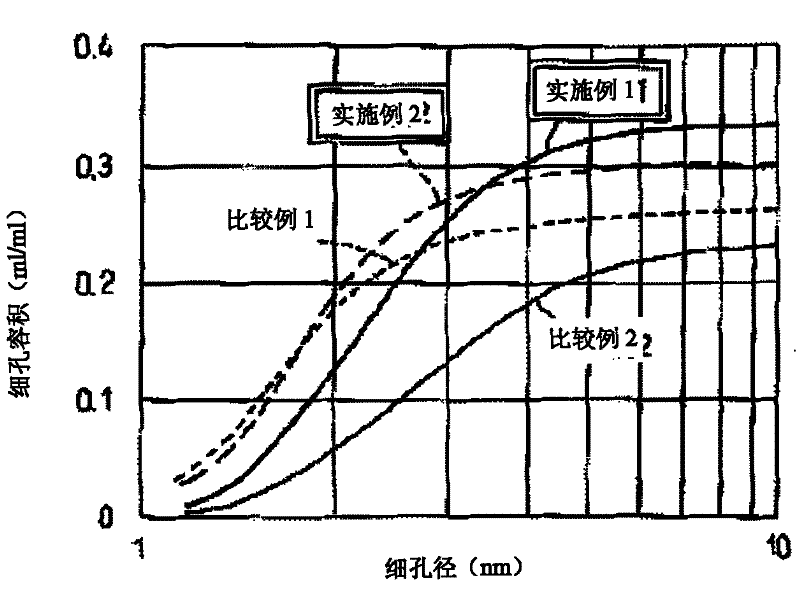

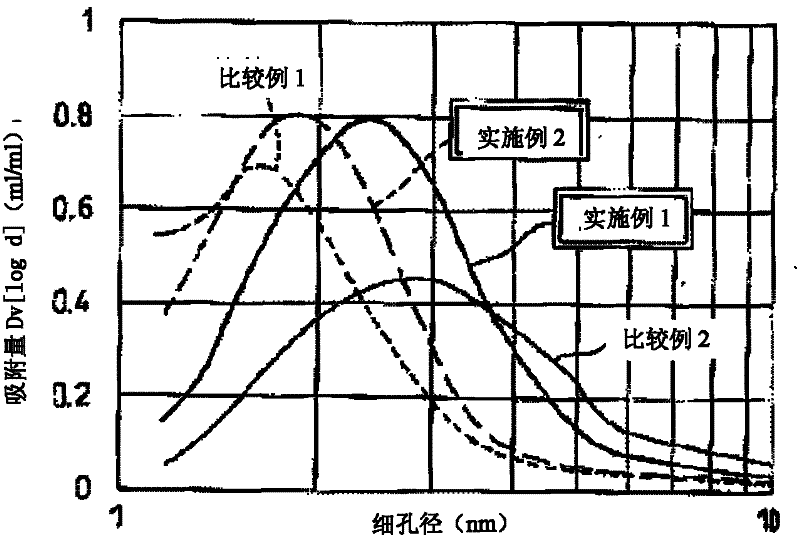

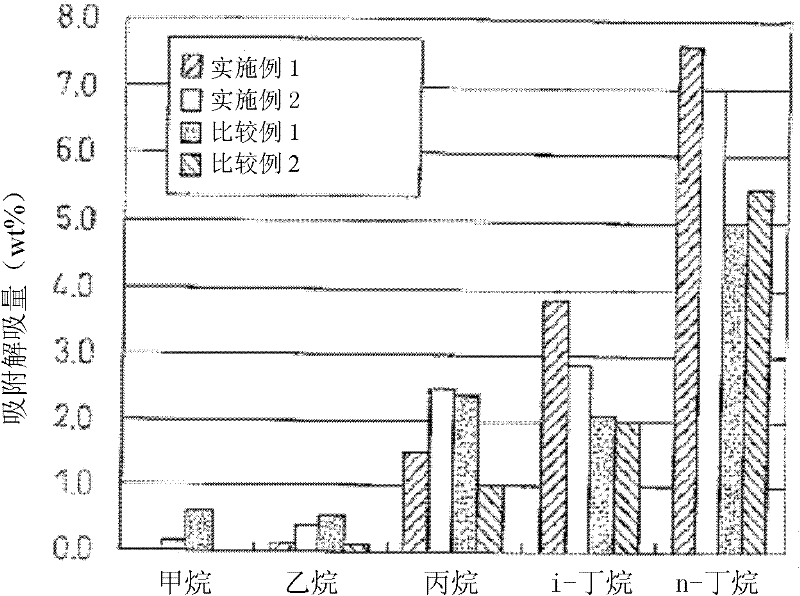

[0040] Form coal tar with coal powder as raw material, after carbonization at 700°C, add H at 5.5g / min 2 O, activated at 950° C. for 8 hours in a water vapor environment, sieved with a JIS sieve to make the average pore diameter 2.9 nm, and prepared the activated carbon for adjusting the natural gas composition of the present invention.

Embodiment 2

[0042] The activated carbon for natural gas component adjustment of the present invention having an average pore diameter of 2.4 nm was prepared in the same manner as in Example 1 except for activation for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com