Numerically controlled turning-grinding combined machine tool

A compound machine tool, turning and grinding technology, applied in the field of CNC machine tools, can solve the problems of large cumulative error in machining accuracy of camshaft parts, long machining cycle, insufficient rigidity, etc., and achieve machining accuracy guarantee, reliable machining accuracy, rigidity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

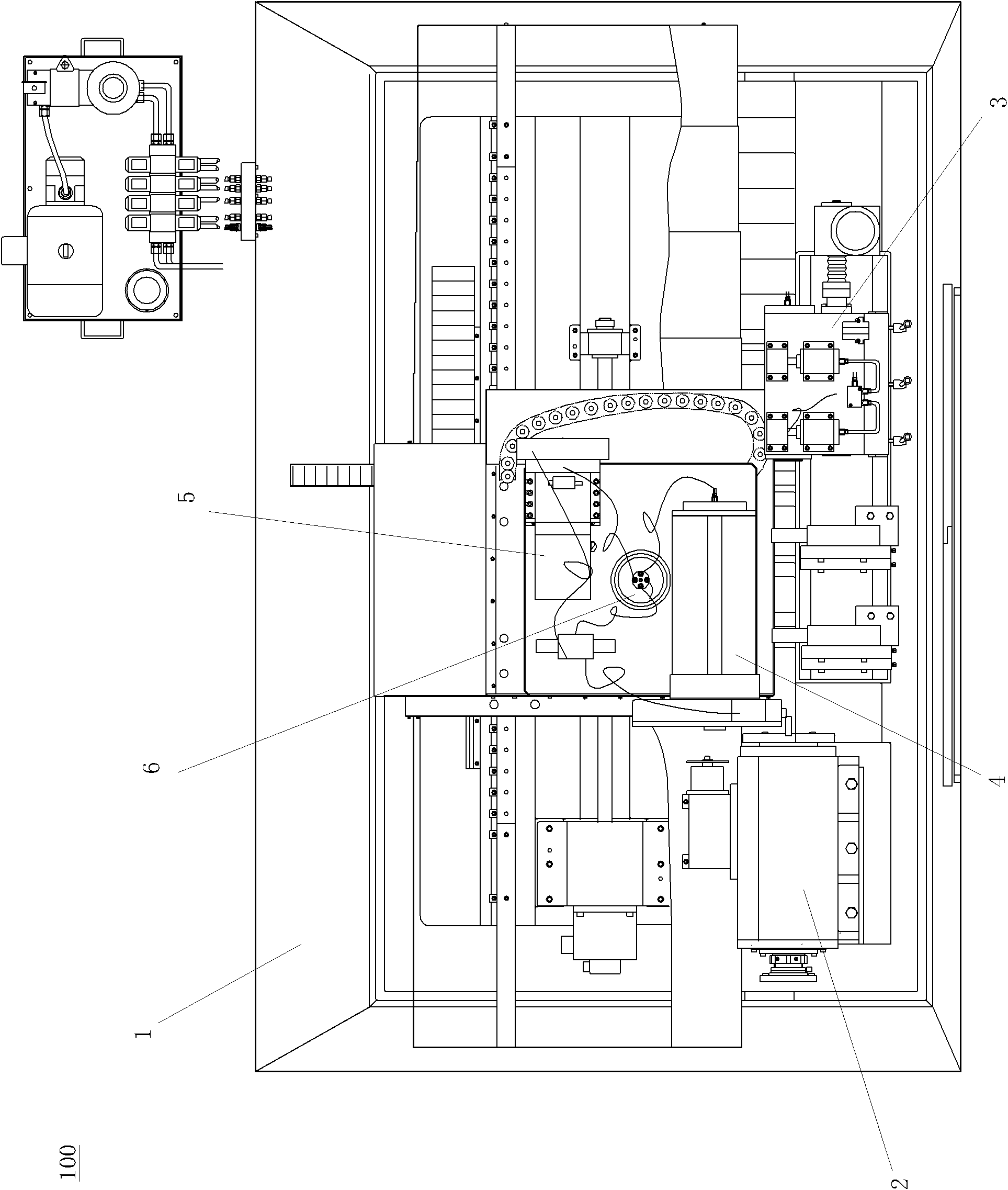

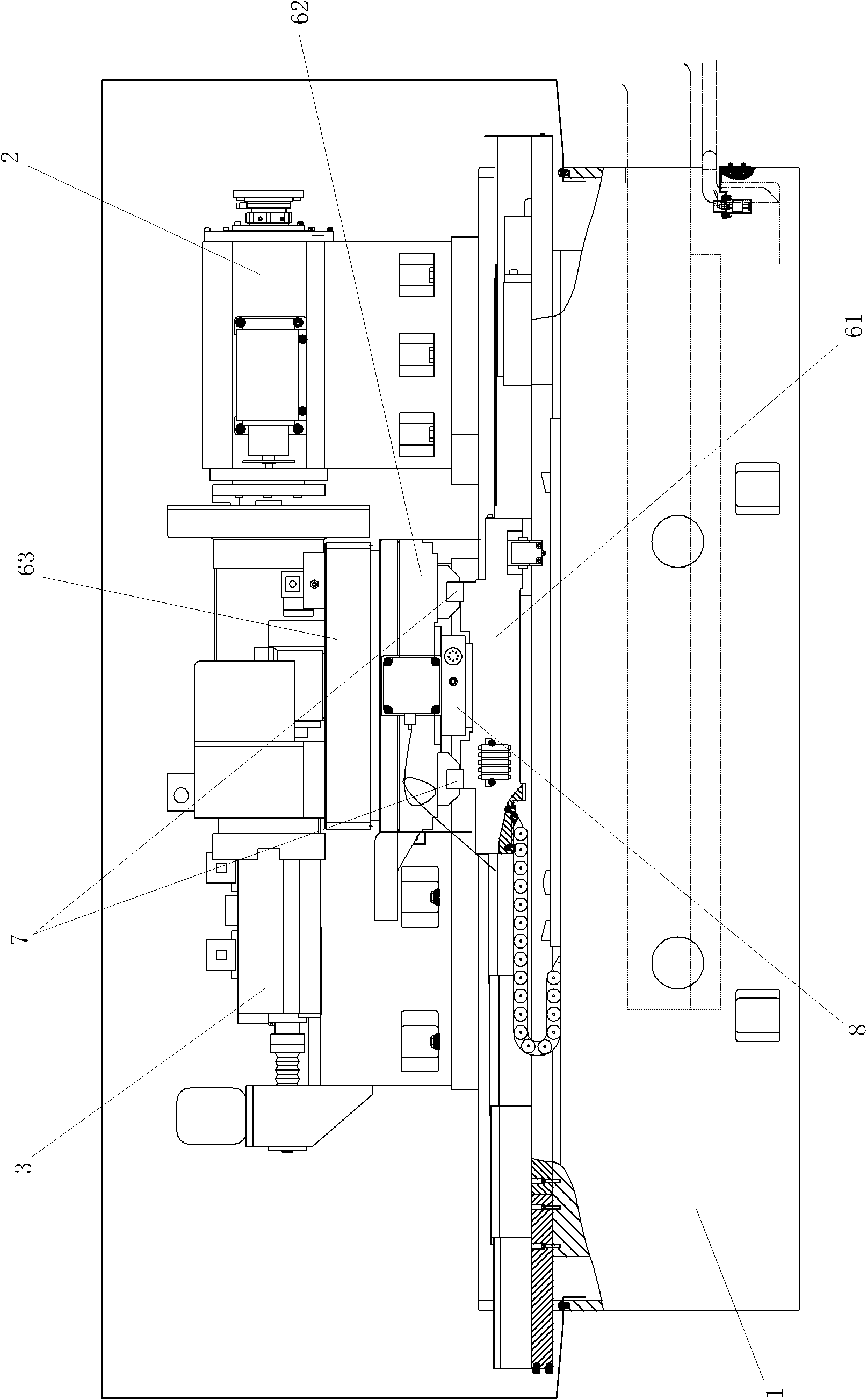

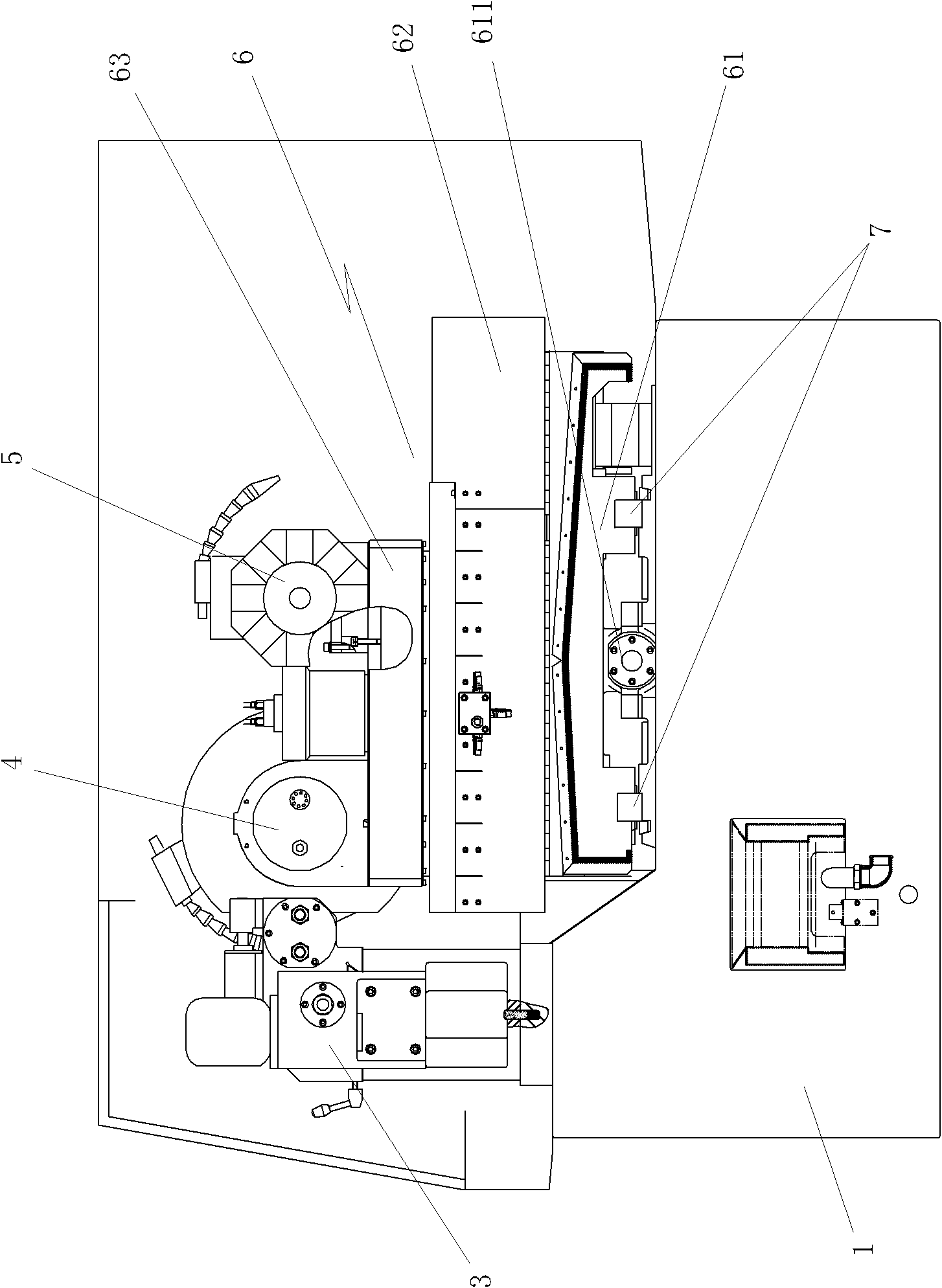

[0030] Such as Figure 1 ~ Figure 4 As shown, the present invention provides a CNC turning-grinding compound machine tool 100. On one side of the upper surface of a rectangular bed 1, a main shaft part 2 and a tailstock 3 corresponding to the main shaft part are provided, and on the other side of the rectangular bed 1, a The workbench 6 supporting grinding wheel frame 4 and turning tool frame 5; Figure 5 As shown, the spindle component 2 is composed of a spindle base 22 and a servo electric spindle 21 arranged on the base, and the front part of the servo electric spindle is provided with a clamping part (not shown) for installing a workpiece. Such as figure 2 , image 3 and Figure 4 As shown, the workbench 6 includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com