Method for preparing unary or binary patterning colloidal photonic crystal

A colloidal photonic crystal and patterning technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of complex preparation process, limited application range, high cost, etc., and achieve simple operation and broad application prospects , the effect of uniform thickness and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

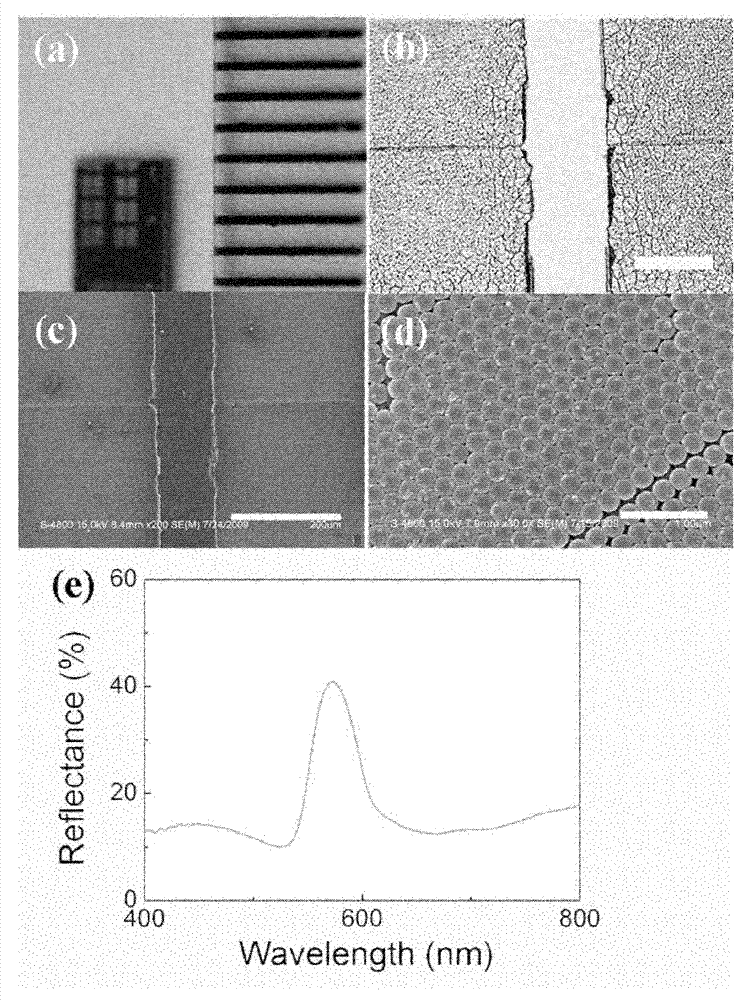

Embodiment 1

[0029] 1) Spin-coat a layer of photoresist with a thickness of 2 microns on a clean and hydrophilic silicon substrate. After etching, obtain patterned substrate, on this patterned substrate, use vacuum evaporation method (vacuum degree is 10 -3 Pa) prepare one deck thickness to be the chromium layer of 2 nanometers, on the chromium layer, use vacuum evaporation method again (vacuum tightness is 10 -3 Pa) After preparing a layer of copper layer with a thickness of 20 nanometers, the substrate is inserted into an aqueous dispersion containing monodisperse 250nm polystyrene microspheres (the volume percentage of polystyrene microspheres is 0.1%, and the degree of dispersion is 3 %) at a constant temperature of 65°C to obtain a unitary patterned colloidal photonic crystal film with a thickness of 2 microns on the surface of the substrate;

[0030] 2) Soak the substrate obtained in step 1) in an ethanol solvent for 10 minutes, and then ultrasonicate for 2 seconds at an ultrasonic ...

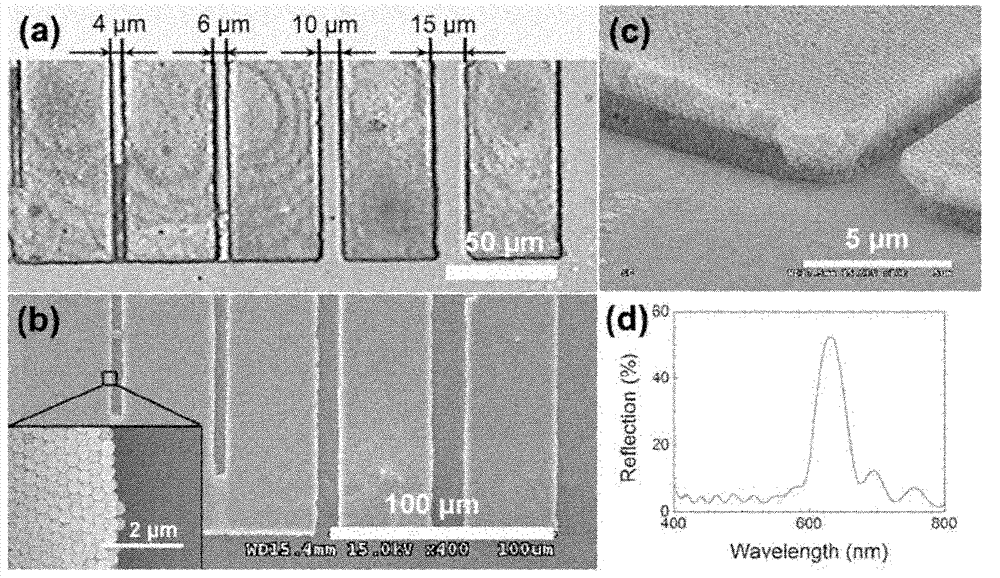

Embodiment 2

[0033] 1) Spin-coat a layer of photoresist with a thickness of 2 microns on a clean and hydrophilic silicon substrate. After etching, obtain patterned substrate, on this patterned substrate, use vacuum evaporation method (vacuum degree is 10 -3 Pa) prepare one deck thickness to be the chromium layer of 2 nanometers, on the chromium layer, use vacuum evaporation method again (vacuum tightness is 10 -3 Pa) After preparing a layer of copper layer with a thickness of 20 nanometers, the substrate is inserted into an aqueous dispersion containing monodisperse 290nm silica microspheres (the volume percentage of silica microspheres is 0.1%, and the degree of dispersion is 5 %) at a constant temperature of 65°C to obtain a unitary patterned colloidal photonic crystal film with a thickness of 2 microns on the surface of the substrate;

[0034] 2) Soak the substrate obtained in step 1) in an acetone solvent for 10 minutes, and then ultrasonicate for 2 seconds at an ultrasonic power of 2...

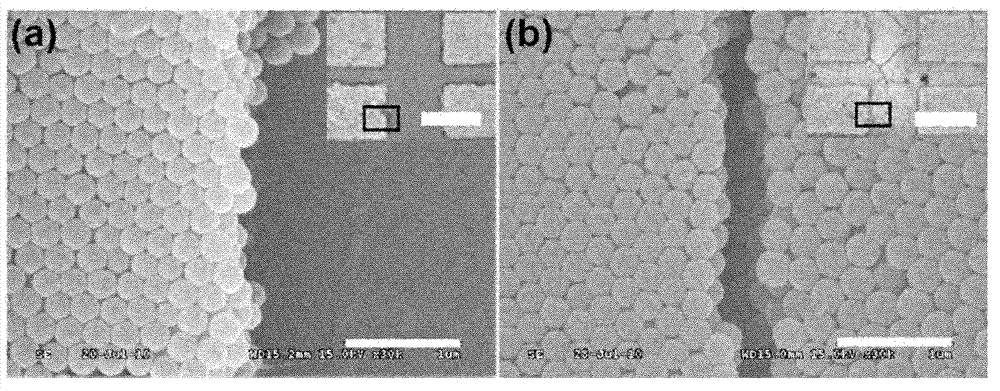

Embodiment 3

[0037] 1) Spin-coat a layer of photoresist with a thickness of 2 microns on a clean and hydrophilic glass substrate. After etching, obtain patterned substrate, on this patterned substrate, use vacuum evaporation method (vacuum degree is 10 -3 Pa) prepare one deck thickness to be the chromium layer of 2 nanometers, on the chromium layer, use vacuum evaporation method again (vacuum tightness is 10 -3 Pa) After preparing a layer of copper layer with a thickness of 20 nanometers, insert the substrate into an aqueous dispersion containing monodisperse 280nm silica microspheres (the volume percentage of silica microspheres is 0.1%, and the degree of dispersion is 2 %) at a constant temperature of 65°C to obtain a unitary patterned colloidal photonic crystal film with a thickness of 2 microns on the surface of the substrate;

[0038] 2) The monolithic patterned colloidal photonic crystal film obtained in step 1) is subjected to vapor deposition (vacuum degree of 3000Pa, deposition t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com