A kind of zirconium-based superalloy solder and its preparation method

A high-temperature alloy and brazing material technology, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of unusable and short life, and achieve the effect of uniform melting, excellent high temperature performance and good wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

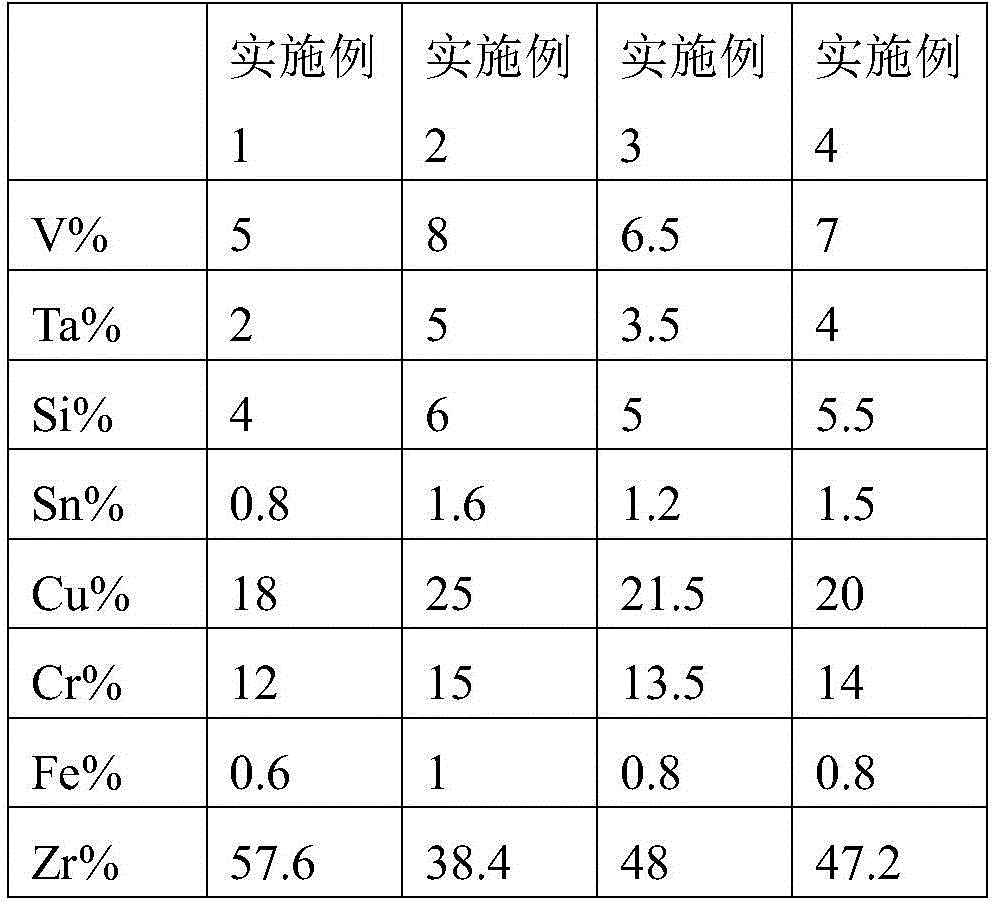

[0026] A zirconium-based superalloy solder, the solder components include V, Ta, Si, Sn, Cu, Cr, Fe and Zr, the addition of the element Ta promotes the precipitation of the γ′ phase and delays the aggregation and growth of the γ′ phase Process, grain refinement, thus improving the high temperature strength of zirconium-based superalloy solder. Adding elements Si and Sn reduces the solubility of the solder matrix, improves the fluidity of the alloy, does not form a second phase solid solution, and improves the plasticity and forming ability of the alloy solder. Adding elements V and Ta, because the atomic radii of these two elements are quite different from Zr, enhances the solid solution strengthening effect of γ and γ′, and not only improves the interatomic bonding force, recrystallization temperature and Diffusion activation energy, and more effectively improve the thermal strength of the alloy solder. Add elements Cu, Cr and Fe to form γ solid solution and γ′ phase, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com