Microscale phase change heat collector for solar disc type heat generation system

A technology of a thermal power generation system and a heat collector, applied in the field of heat collectors, can solve the problems of short life of heat absorbers, difficult processing and packaging, etc., and achieve the effects of uniform temperature field, good heat preservation effect and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

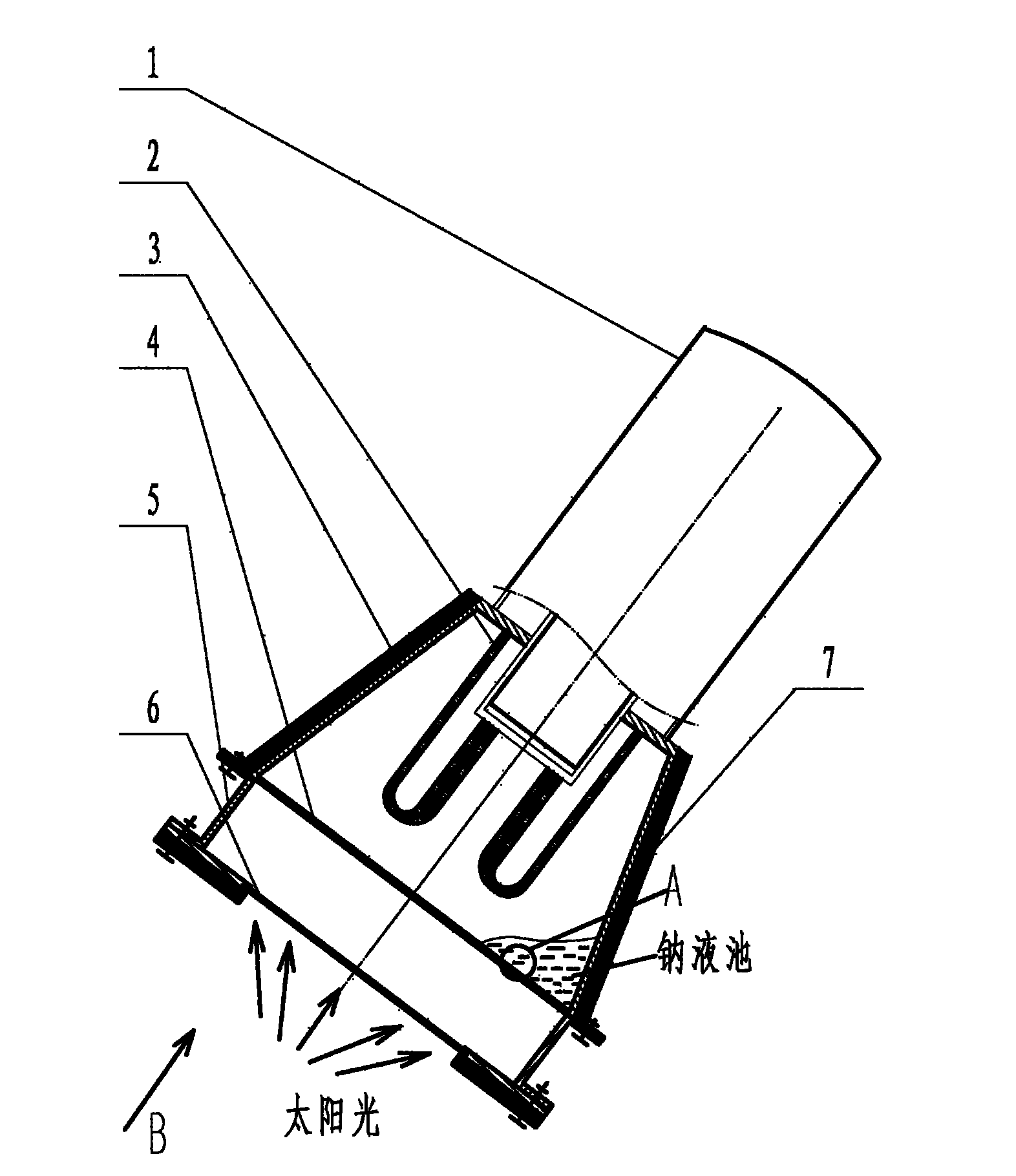

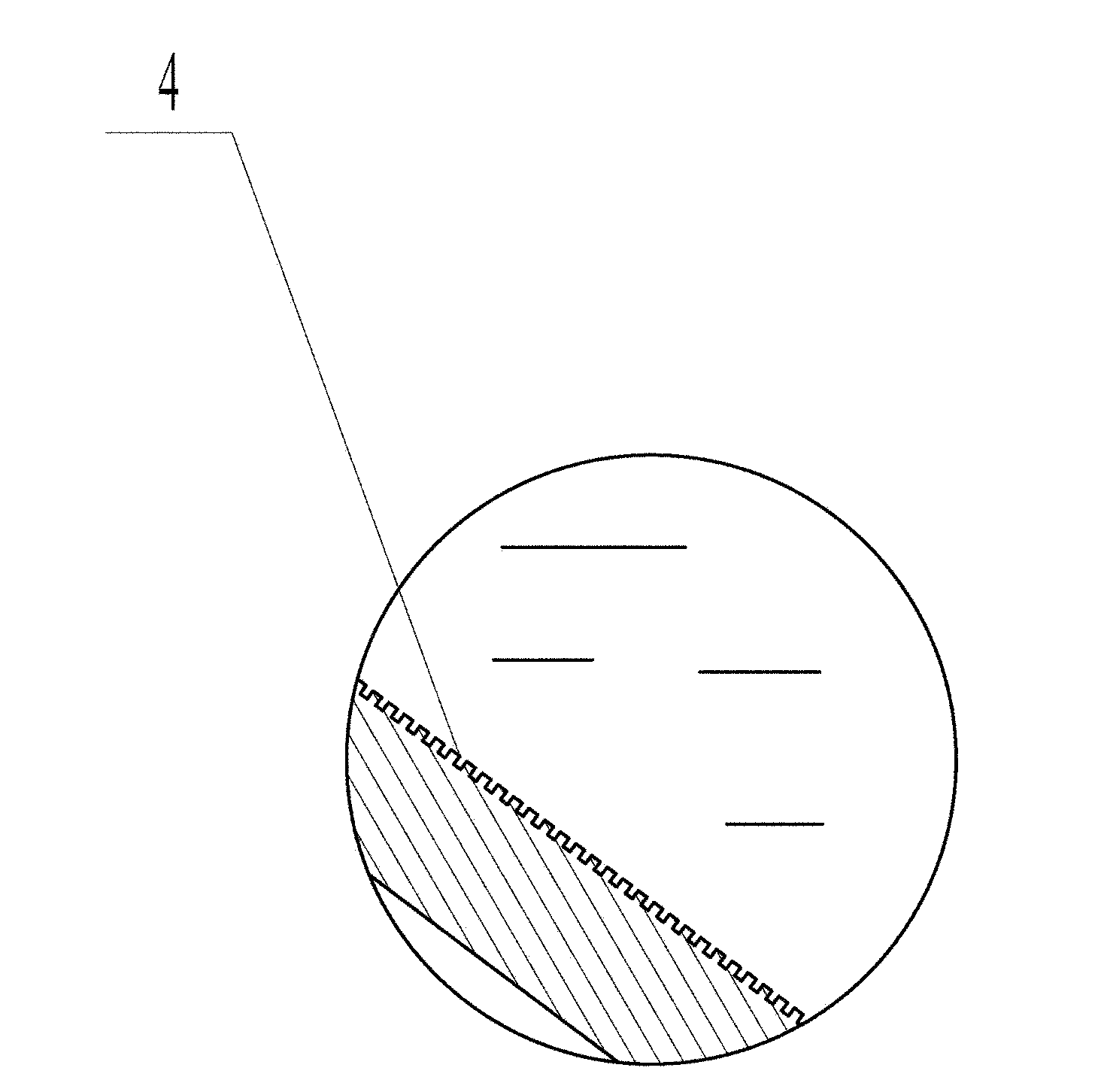

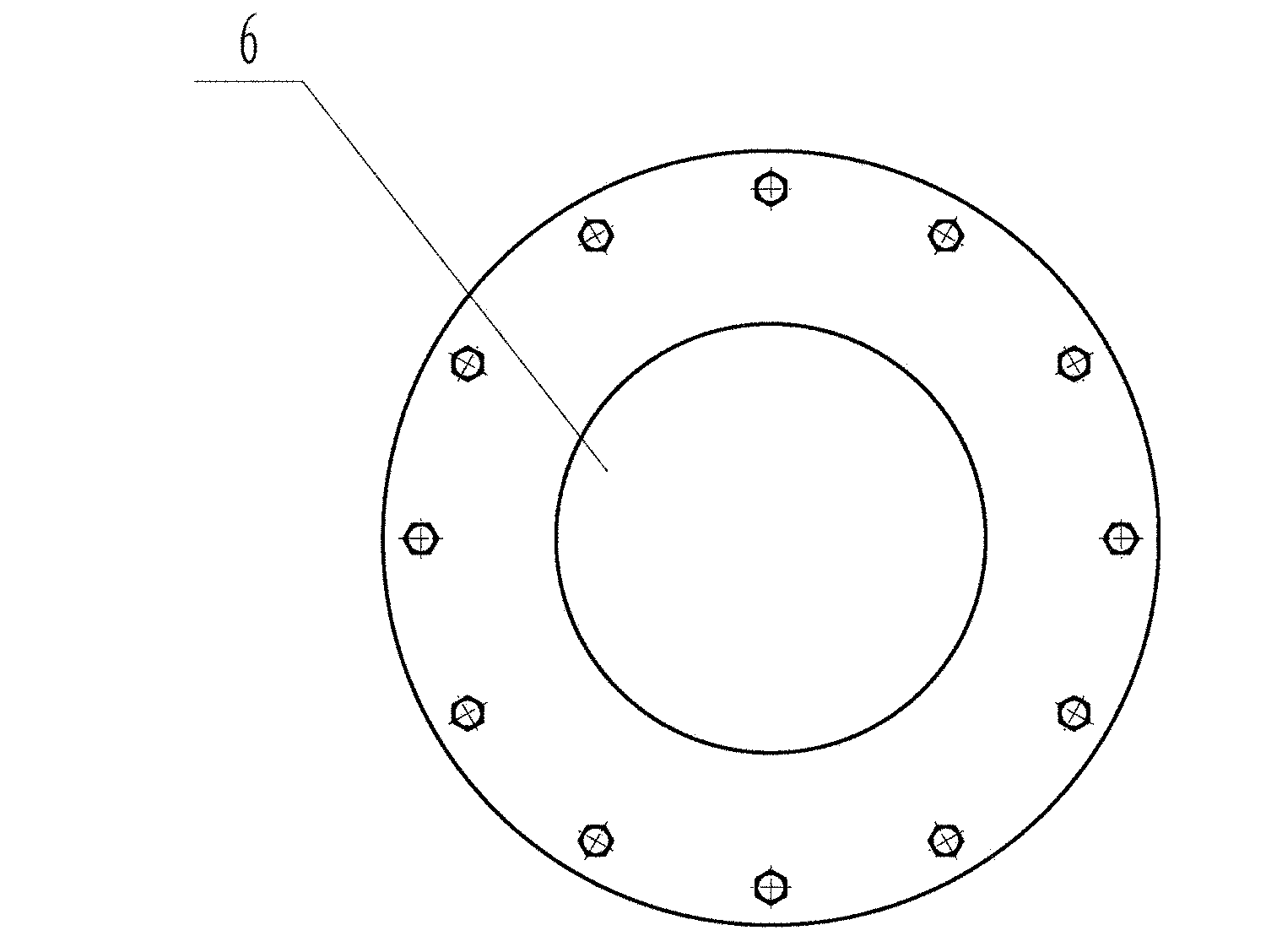

[0015] The structure of the present invention is as figure 1 , it is mainly composed of the heat absorber 2 of the Stirling machine, the wall of the heat collector cavity 3, the micro-groove plate 4, the pupil cavity 5, the pupil 6, and the high temperature resistant thermal insulation coating layer 7. When manufacturing, first select a stainless steel plate with a certain thickness, and engrave rectangular micro-grooves criss-cross on one side of the plate. The width of each engraved micro-groove is less than 0.2mm, the depth is about 0.5mm, and the side wall thickness is about 0.5mm; In this way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com