Wind machine blade airfoil family

A technology of wind turbine blade and airfoil family, which is applied to wind turbines, wind turbines, engines and other directions that are consistent with the wind direction, can solve the problem of increasing the roughness sensitivity of the leading edge of the airfoil, reducing the aerodynamic performance of the airfoil, and the maximum airfoil. Lift coefficient and maximum lift-to-drag ratio are reduced to achieve excellent aerodynamic characteristics, improve blade performance, and reduce blade cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described specific embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

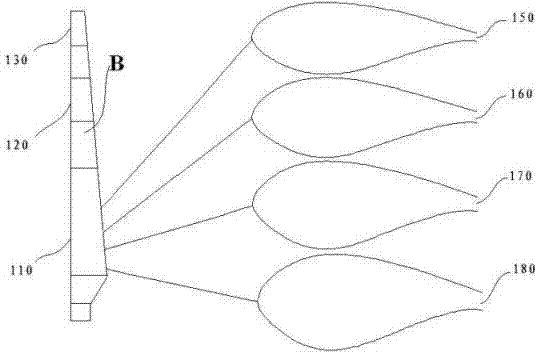

[0022] now refer to figure 1 , figure 1 A wind turbine blade B using the wind turbine blade airfoil family A of the present invention is shown. The wind turbine blade airfoil family of the present invention can preferably be used for horizontal axis wind turbine blades. Blade B includes an inboard region 110 , an outboard region 120 and a tip region 130 in close proximity to a hub (not shown). Generally, the inner region 110 accounts for about 50% of the length of the blade 100 , the outer region accounts for about 30% of the length of the blade 100 , and the tip region 130 accounts for about 20% of the length of the blade 100 .

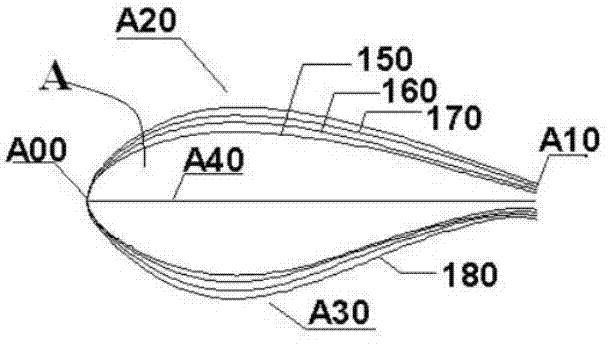

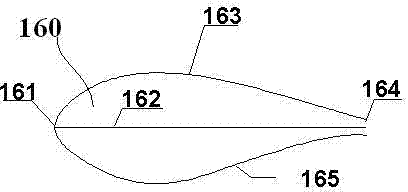

[0023] figure 2 A wind turbine airfoil family A of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com