Semiconductor chip assembly with post/base heat spreader and substrate

A technology for semiconductors and heat sinks, applied in the field of semiconductor chip assemblies, can solve the problems of limited routing capability, too large volume, and unsuitable for low-cost mass production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, in conjunction with the accompanying drawings and preferred embodiments, the following is a description of the semiconductor chip set with the heat sink of the boss / substrate and the substrate according to the present invention. The detailed description of its specific implementation, structure, features and effects is as follows.

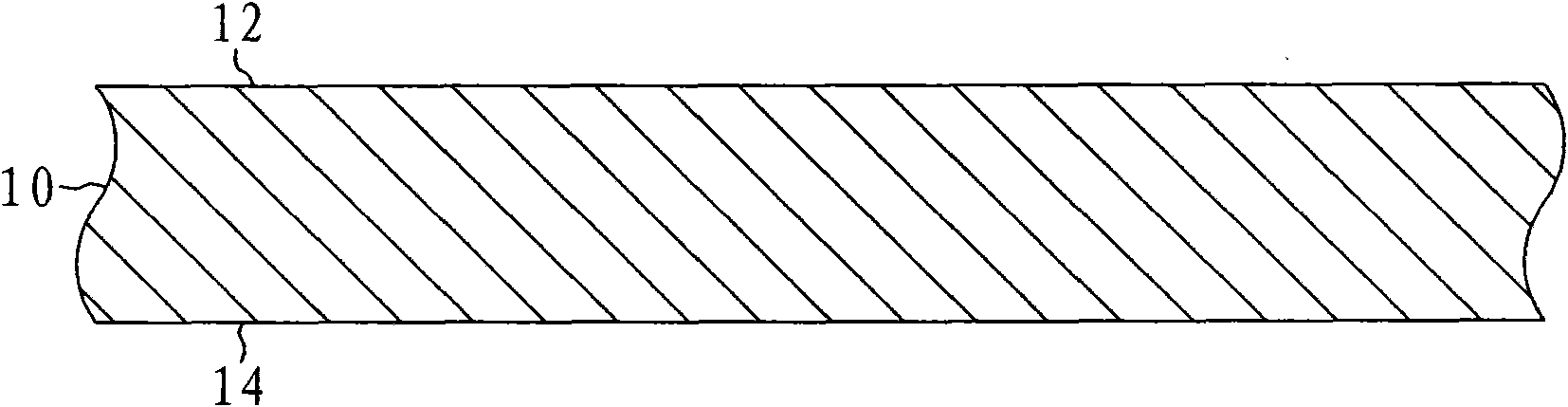

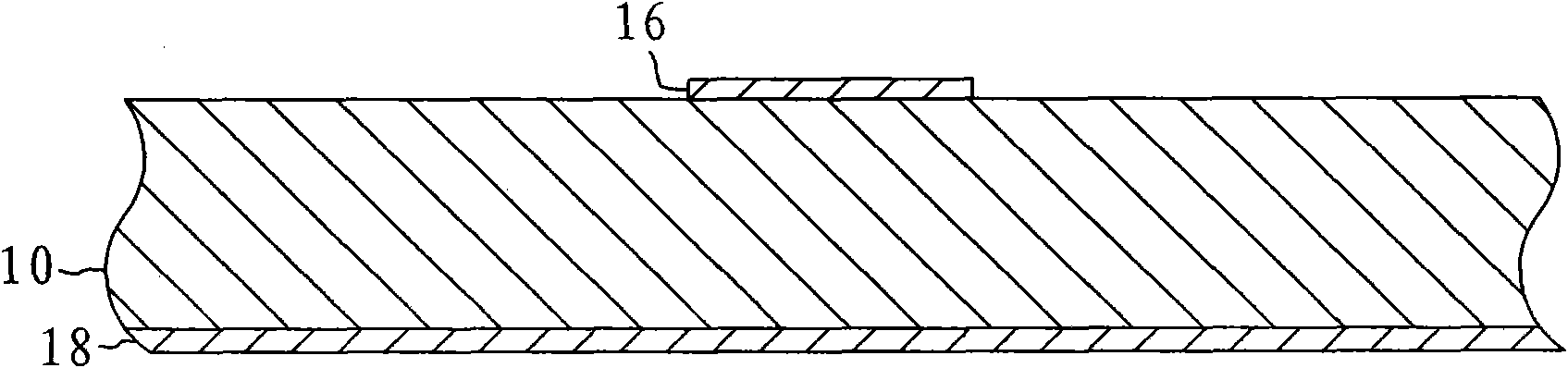

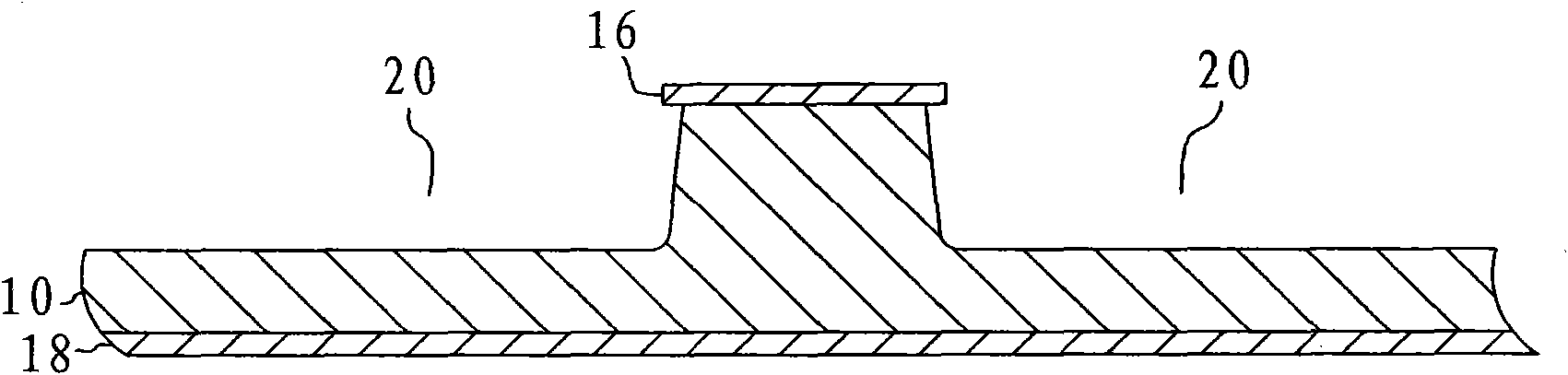

[0077] Figure 1 to Figure 4 It is a cross-sectional view illustrating a method of manufacturing a protrusion and a base in an embodiment of the present invention. Figure 5 and Image 6 Respectively Figure 4 Top view and bottom view of.

[0078] figure 1 It is a cross-sectional view of the metal plate 10, and the metal plate 10 includes main surfaces 12 and 14 opposite to each other. The illustrated metal plate 10 is a copper plate with a thickness of 500 microns. Copper has the advantages of high thermal condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com