Reflected light damage preventing device for high-power semiconductor laser

A semiconductor and laser technology, applied in the laser field to prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

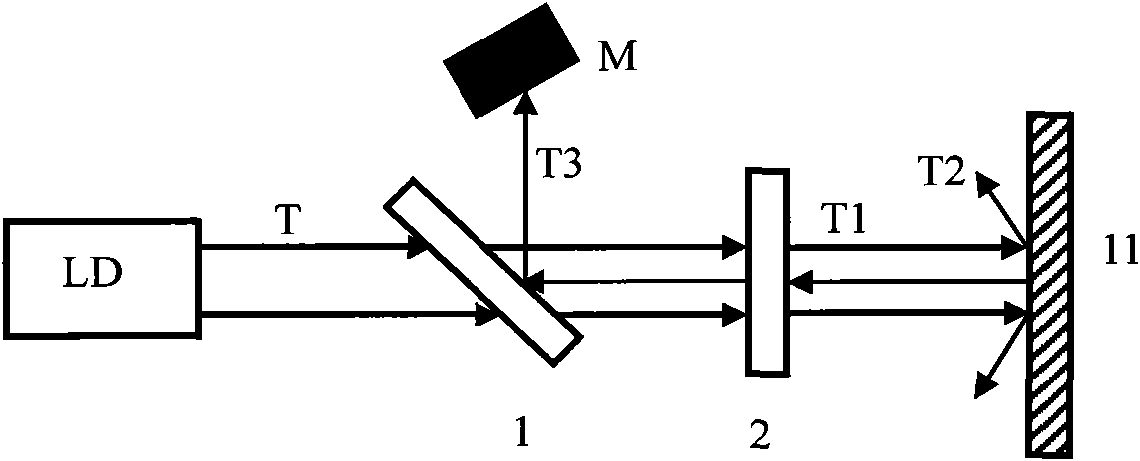

Embodiment 1

[0025] like figure 1 As shown, the outgoing light of the semiconductor laser light-emitting chip is P-linearly polarized light, which mainly includes a polarization beam splitter 1 placed at an angle of 45 degrees to the optical axis. , the λ / 4 transmissive wave plate 2 placed perpendicular to the optical axis and the absorber M placed at an angle of 45 degrees to the optical axis. The P-linearly polarized beam T emitted from the semiconductor laser light-emitting chip with a wavelength of λ is still a P-linearly polarized beam after passing through the polarizing beam splitter 1, and then becomes a circularly polarized beam T1 after passing through the λ / 4 wave plate 2, and the circularly polarized beam T1 is irradiated After reaching the workpiece 11, part of the beam T2 reflected by the workpiece 11 returns along the original outgoing optical path, and becomes an S-linearly polarized beam T3 after passing through the λ / 4 wave plate 2 again, and the S-linearly polarized beam...

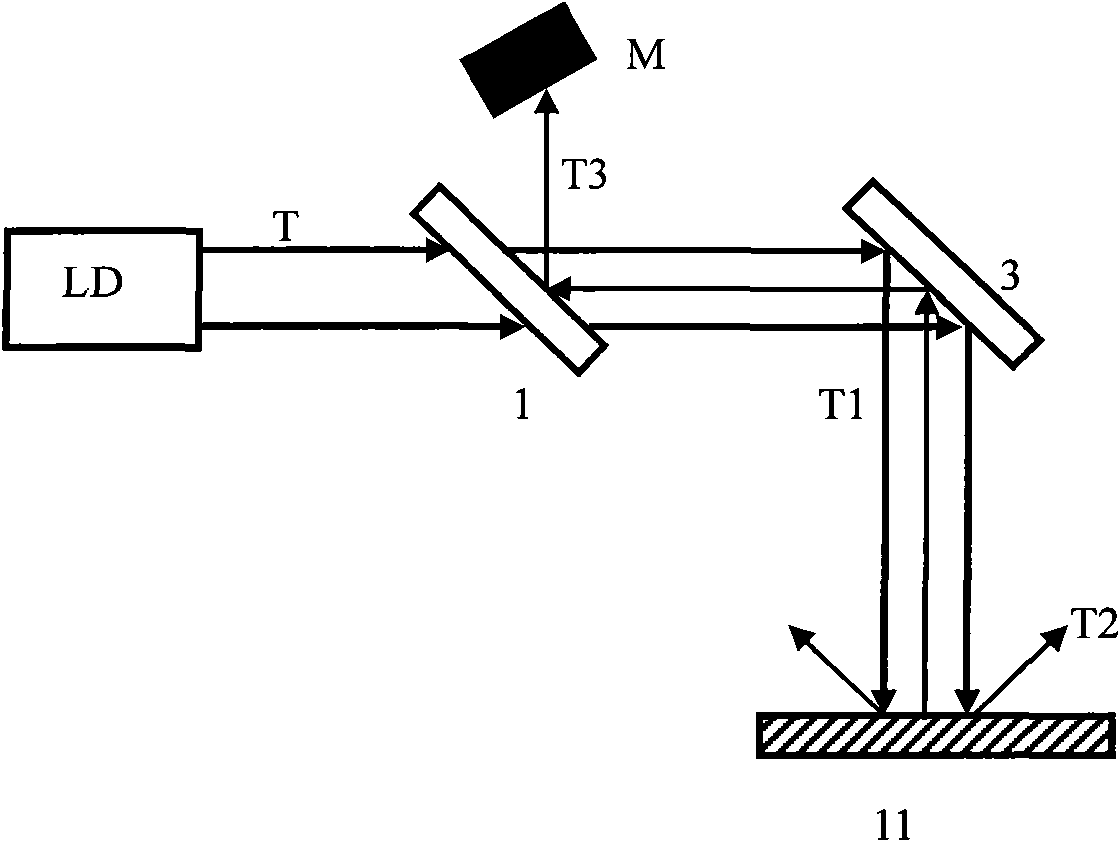

Embodiment 2

[0027] like figure 2 As shown, wherein, λ / 4 wave plate 2 is a reflective wave plate, which is placed at an angle of 45 degrees to the optical axis, and the rest of the settings are the same as in embodiment 1.

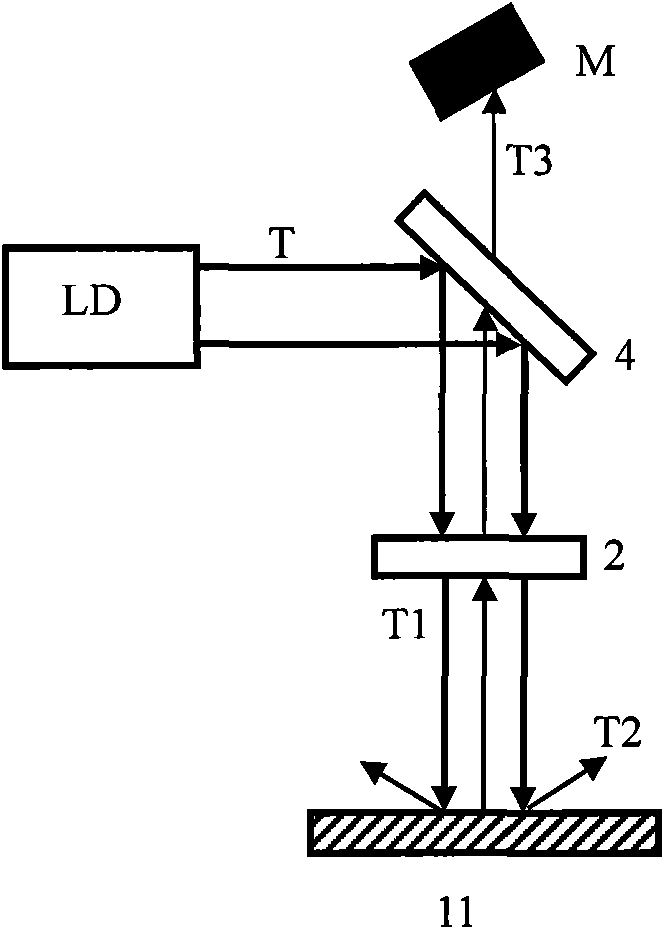

Embodiment 3

[0029] like image 3 As shown, wherein, the polarizing beam splitter 4 is a reflective beam splitter for S-linearly polarized light transmission and P-linearly polarized light, and the rest of the settings are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com