Alloy bone nail and manufacturing process thereof

A manufacturing process and technology of bone nails, applied in the direction of internal bone synthesis, fixers, fastening devices, etc., can solve the problems of insufficient research and reports, and achieve the goal of promoting bone growth, uniform force, and promoting surgical recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

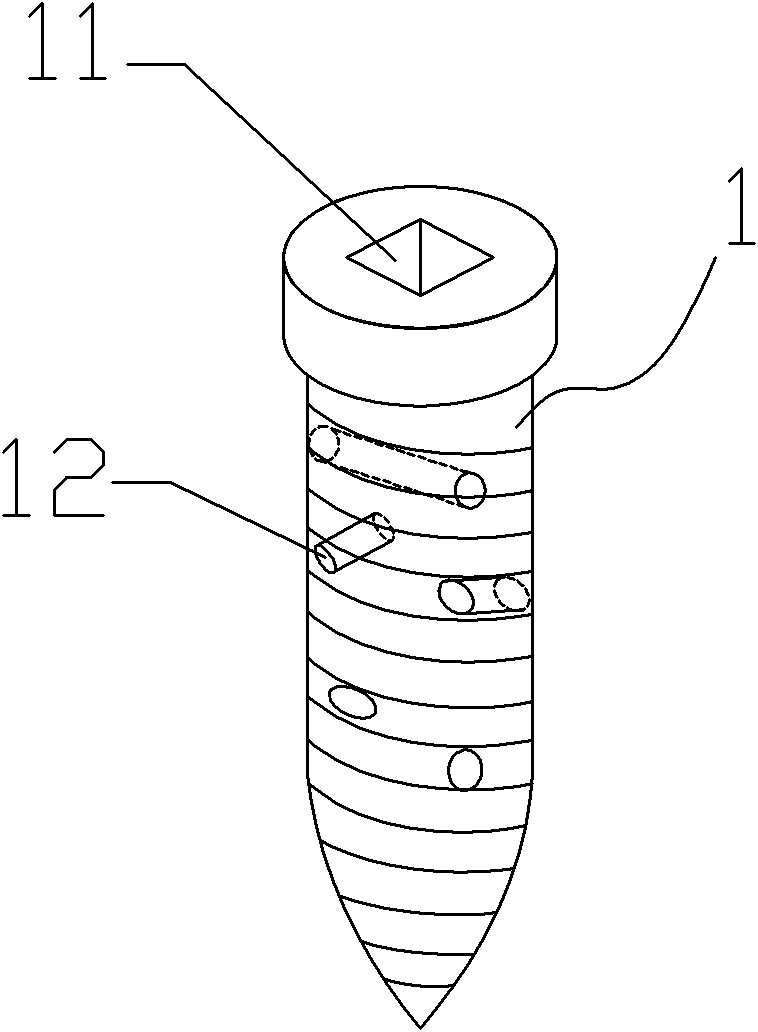

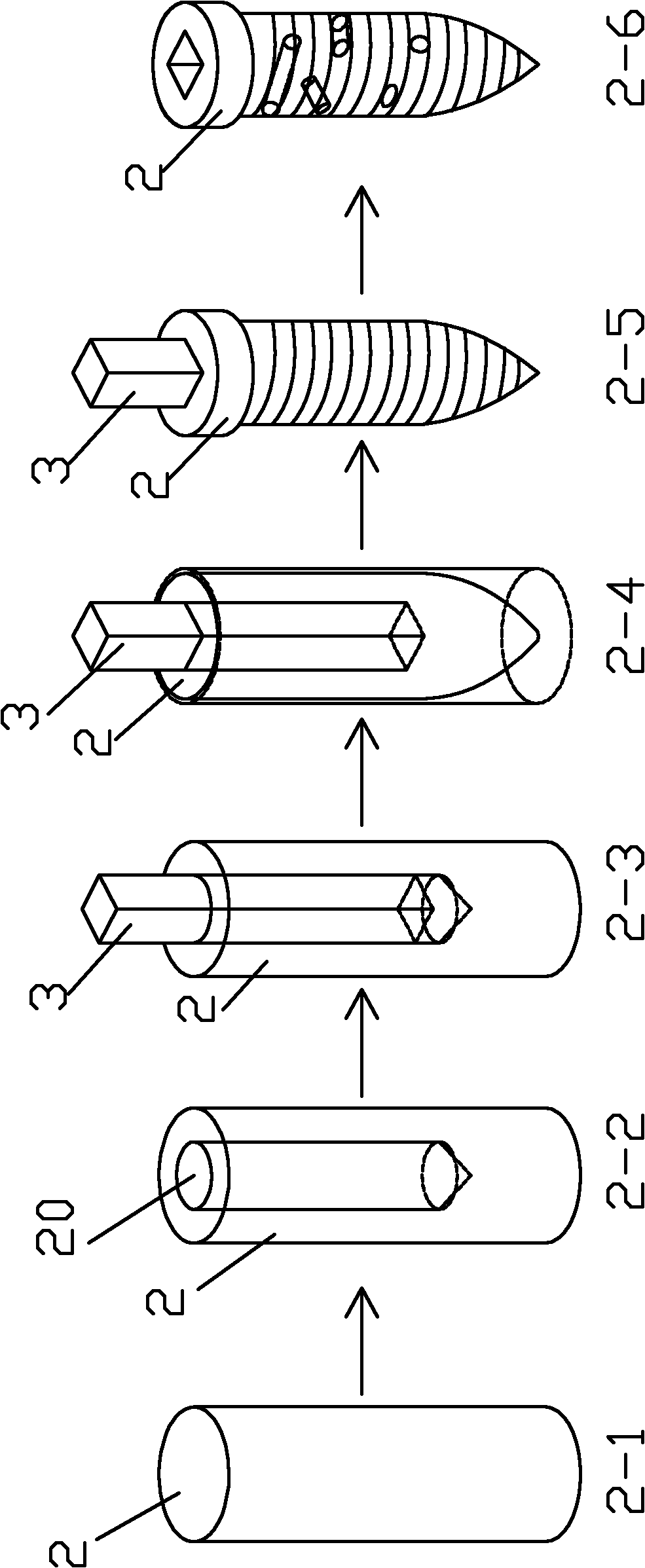

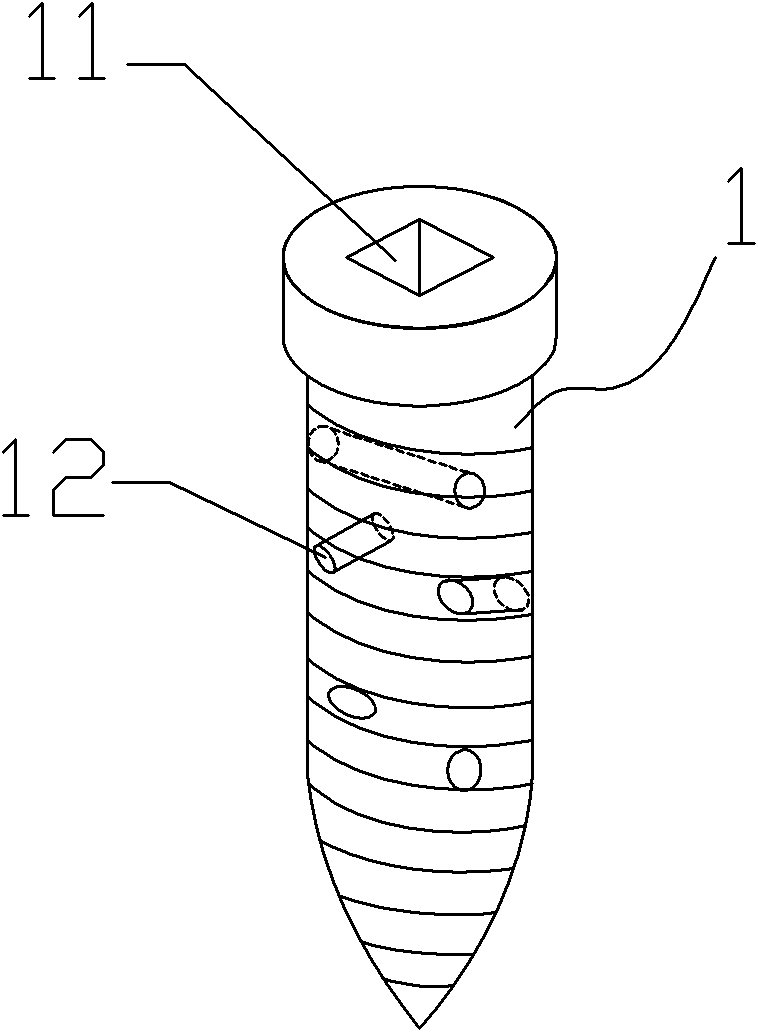

[0021] Such as figure 1 As shown, the alloy bone screw of the present invention has a bone screw body 1, the bone screw body 1 has an axial insertion hole 11 with a non-circular cross section, and the bone screw body also has several non-axial To the through hole 12.

[0022] In the alloy bone screw of the present invention, the axial and non-circular cross-section socket 11 on the bone screw body 1 is used to deeply insert the screwdriver corresponding to the shape of the socket 11 when implanting. In the jack hole 11, the rotation implantation operation is carried out, which is conducive to making the overall force of the bone nail uniform and stable, without slipping teeth or bone nail breakage, and ensuring the smooth progress of the implantation operation; the function of the non-axial through hole 12 is After the bone nail is implanted, bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com