Compound anti-blocking herniorrhaphy patch and preparation method thereof

A production method and anti-adhesion technology, which are applied in medical science, prosthesis and other directions, can solve the problems of intolerance of infection and pollution, inability of tissue to grow in, and difficult to heal wounds, and achieve simple structure, easy mass production, and production method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

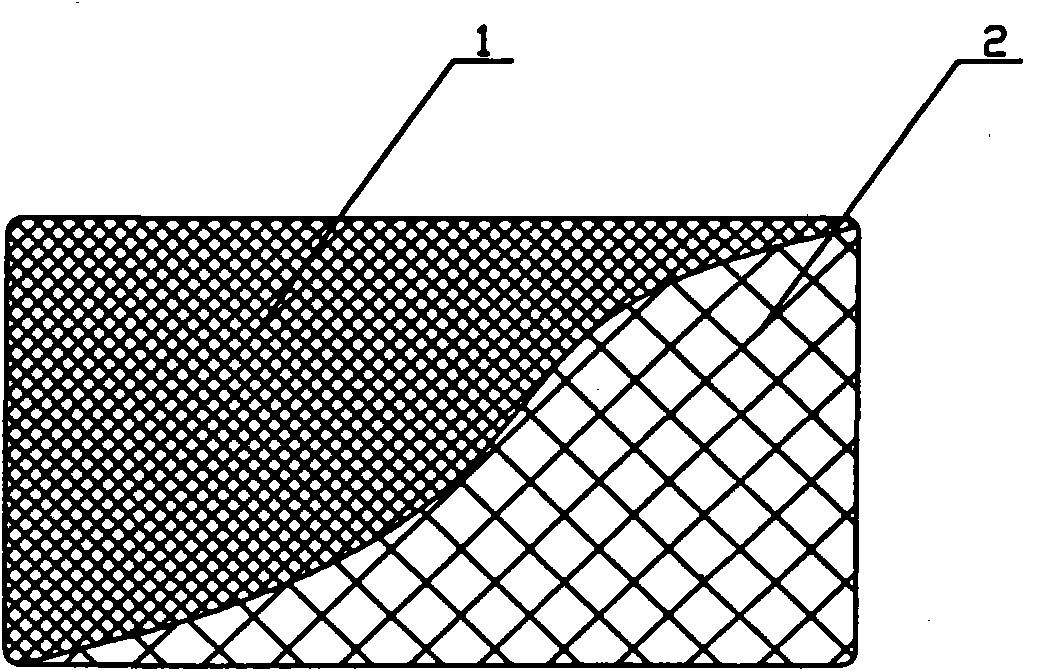

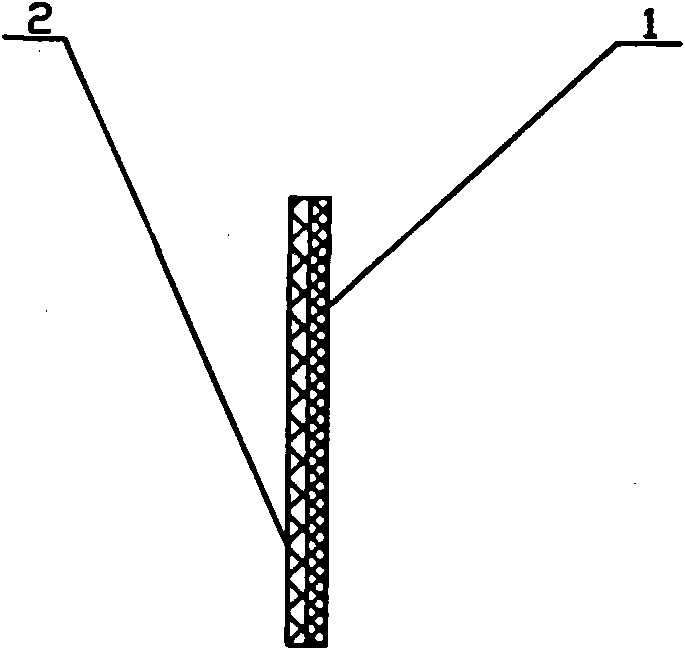

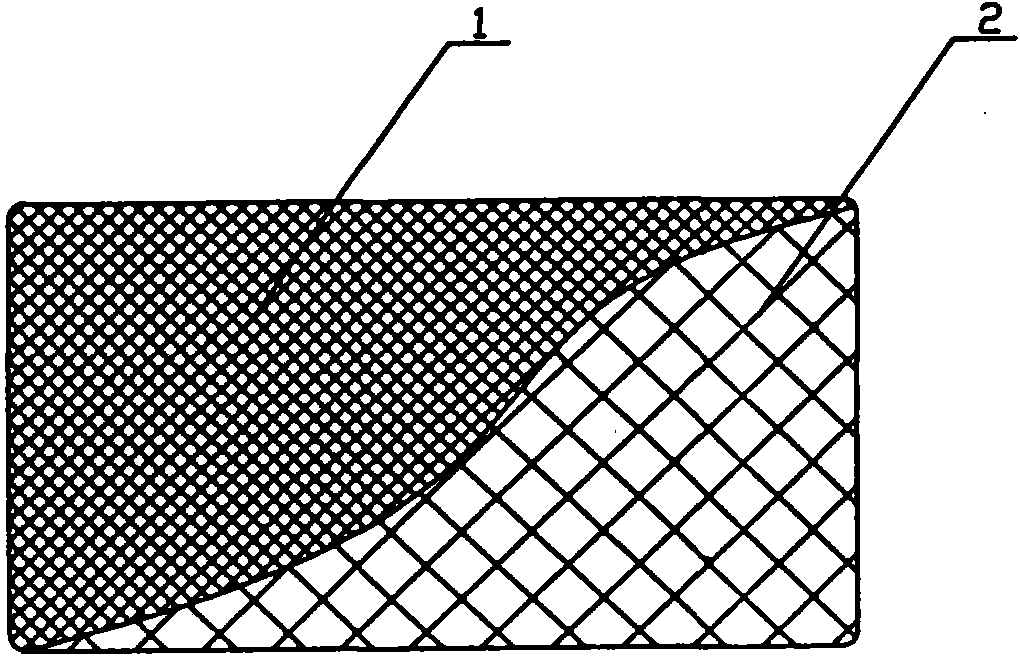

[0026] Refer to attached figure 1 , 2 The composite anti-adhesion hernia repair patch comprises a polypropylene patch 2 and an expanded polytetrafluoroethylene anti-adhesion patch 1, and the polypropylene patch 2 and the expanded polytetrafluoroethylene anti-adhesion patch 2 adopt expanded polytetrafluoroethylene stitched together.

[0027] The polypropylene patch 2 adopts a tension-free polypropylene patch, which is a mesh braid (commercially available).

[0028] The expanded polytetrafluoroethylene anti-adhesion patch 1 is a film structure (commercially available).

[0029] The material thickness of the polypropylene patch 2 is 0.1 mm to 1 mm, and the weight is 12.5 g to 125 g per square meter.

[0030] The material thickness of the expanded polytetrafluoroethylene anti-adhesion patch 1 is 0.05 mm to 0.5 mm.

[0031] The method of making composite anti-adhesion hernia repair sheet is as follows:

[0032] 1. The polypropylene mesh fabric is cut into a polypropylene patch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com