Method for scheduling machine part processing line by adopting discrete quantum particle swarm optimization

A particle swarm algorithm and discrete quantum technology, applied in the field of machine parts processing pipeline scheduling based on discrete quantum particle swarm algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

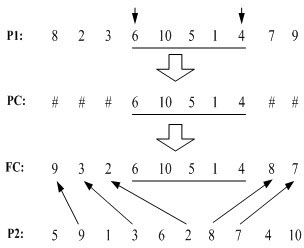

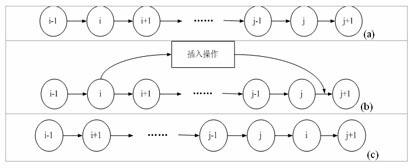

Method used

Image

Examples

Embodiment

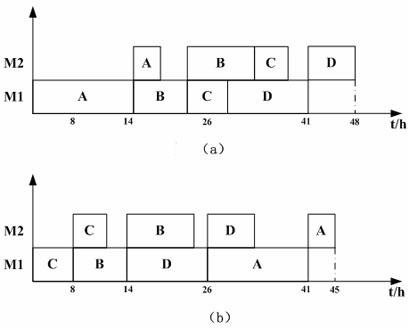

[0093] The method of the present invention is used for the scheduling of the bearing processing sequence as follows, and is further described in detail:

[0094] To process four kinds of bearings (that is, workpieces) A, B, C, and D, according to the processing technology, it is necessary to turn first and then mill. The processing time is shown in the table below. There is a lathe and a milling machine , it is necessary to determine the optimal processing sequence of these four bearings

[0095] artifact name lathe Working hours / h milling machine Working hours / h A 15 4 B 8 10 C 6 5 D 12 7 total 41 26

[0096] 。[0023] Based on the discrete quantum particle swarm optimization algorithm, the scheduling method of the bearing processing pipeline is as follows:

[0097] 1) Read in the process operation time of bearing processing as a known condition:

[0098] bearing in the machine The processing time on , then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com