Method for preparing flaky lithium vanadium phosphate cathode material of lithium ion battery

A lithium-ion battery, lithium vanadium phosphate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of restricting the development of high-performance lithium-ion battery technology, large investment in industrial production equipment, and cumbersome gel-making process. Safe to use, simple and easy to operate, and excellent in high-rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

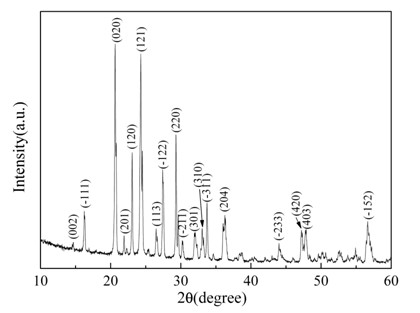

Image

Examples

Embodiment 1

[0022] 1) LiOH·H 2 O and glycine were dissolved in deionized water to prepare LiOH·H with a concentration of 0.09 g / ml 2 O aqueous solution and 0.08 g / ml glycine aqueous solution;

[0023] 2) the NH 4 VO 3 Add to deionized water, stir magnetically, and prepare white turbid NH with a concentration of 0.1 g / ml 4 VO 3 solution, then press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of H 3 PO 4 Added to the above NH 4 VO 3 solution, a brownish-red solution was obtained;

[0024] 3) Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of step 1) LiOH·H 2 O aqueous solution was added to the brown-red solution prepared in step 2), stirred and mixed, and then the glycine aqueous solution in step 1) was added, and the amount of glycine was LiOH·H 2 O. NH 4 VO 3 and H 3 PO 4 2% of the total weight, after stirring and mixing, add NH 4 VO 3 10% Super P by weight, and then stirred for 1 h; added ammonia water to adjust the pH value of the solution to 2, and then dried...

Embodiment 2

[0030] 1) LiOH·H 2 O and glycine were dissolved in deionized water to prepare LiOH·H with a concentration of 0.10 g / ml 2 O aqueous solution and 0.09 g / ml glycine aqueous solution;

[0031] 2) the NH4 VO 3 Add to deionized water, stir magnetically, and prepare white turbid NH with a concentration of 0.1 g / ml 4 VO 3 solution, then press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of H 3 PO 4 Added to the above NH 4 VO 3 solution, a brownish-red solution was obtained;

[0032] 3) Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of step 1) LiOH·H 2 O aqueous solution was added to the brown-red solution prepared in step 2), stirred and mixed, and then the glycine aqueous solution in step 1) was added, and the amount of glycine was LiOH·H 2 O. NH 4 VO 3 and H 3 PO 4 5% of the total weight, after stirring and mixing, add NH 4 VO 3 10% Super P by weight, and then stirred for 1 h; added ammonia water to adjust the pH value of the solution to 3, and then dried t...

Embodiment 3

[0038] 1) LiOH·H 2 O and glycine were dissolved in deionized water to prepare LiOH·H with a concentration of 0.12 g / ml 2 O aqueous solution and 0.11 g / ml glycine aqueous solution;

[0039] 2) the NH 4 VO 3 Add to deionized water, stir magnetically, and prepare white turbid NH with a concentration of 0.1 g / ml 4 VO 3 solution, then press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of H 3 PO 4 Added to the above NH 4 VO 3 solution, a brownish-red solution was obtained;

[0040] 3) Press Li 3 V 2 (PO 4 ) 3 The stoichiometric ratio of step 1) LiOH·H 2 O aqueous solution was added to the brown-red solution prepared in step 2), stirred and mixed, and then the glycine aqueous solution in step 1) was added, and the amount of glycine was LiOH·H 2 O. NH 4 VO 3 and H 3 PO 4 10% of the total weight, after stirring and mixing, add NH 4 VO 3 10% Super P by weight, and then stirred for 1 h; added ammonia water to adjust the pH value of the solution to 5, and then drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com