Catalyst using SBA-16 molecular sieve as carrier, and preparation method and application thereof

A catalyst and molecular sieve technology, applied in the field of inorganic catalyst preparation, can solve the problems of wide pore size distribution and difficult synthesis, and achieve the effects of high cobalt loading, improved product selectivity, and reduced methane selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

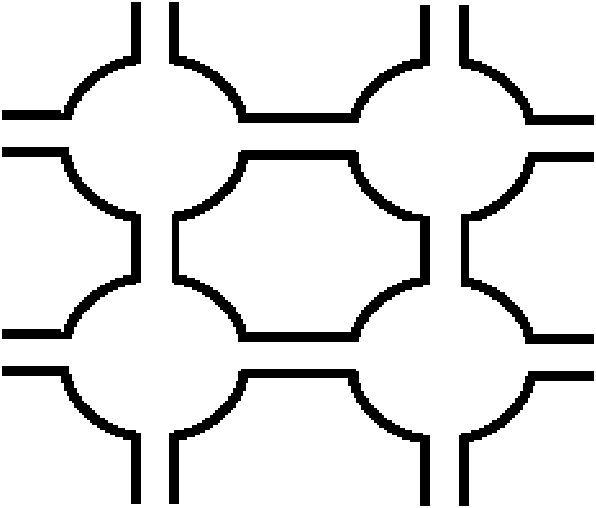

Image

Examples

Embodiment 1

[0022] At 35℃, mix 12g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , M A =5800) and 61g polymer surfactant F-127(C 3 H 6 O·C 2 H 4 O) X Dissolve in 3400ml of 2mol / L hydrochloric acid, stir until completely dissolved, then add 283ml of ethyl orthosilicate (TEOS), stir for 24h, then transfer to the polytetrafluoroethylene reactor, crystallize at 70℃ for 24h, filter, After washing, drying at 120°C for 5 hours, and finally calcining at 550°C for 5 hours, a cage-shaped molecular sieve SBA-16 (1) with a pore size of 6 nm was obtained.

[0023] Weigh 10.0g of SBA-16(1) molecular sieve dried at 150℃, and then weigh 13.6g of Co(NO 3 ) 2 ·6H 2 O add water to prepare 6ml solution, immerse the solution on SBA-16(1), dry it, dry it in an oven at 120℃ for 12h, and finally put it in a muffle furnace and roast it at 400℃ for 5h to obtain 20% Co / SBA-16(1) catalyst, marked as Cat.1, the content of cobalt in the catalyst is 20wt%.

Embodiment 2

[0025] At 35℃, mix 12g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , M A =5800) and 61g polymer surfactant F-127(C 3 H 6 O·C 2 H 4 O) X Dissolve in 3400ml of 2mol / L hydrochloric acid, stir until completely dissolved, then add 283ml of ethyl orthosilicate (TEOS), stir for 24h, then transfer to the polytetrafluoroethylene reactor, crystallize at 90℃ for 24h, filter, After washing, drying at 120°C for 5 hours, and finally calcining at 550°C for 5 hours, a cage-shaped molecular sieve SBA-16 (2) with a pore size of 10 nm was obtained.

[0026] Weigh 10.0g of SBA-16(2) molecular sieve dried at 150℃, and then weigh 18.8g of Co(NO 3 ) 2 ·6H 2 O add water to prepare 8ml solution, immerse the solution on SBA-16(2), dry it, dry it in an oven at 120℃ for 12h, and finally put it in a muffle furnace and roast it at 400℃ for 5h to get 25% Co / SBA-16(2) catalyst, marked as Cat. 2, the content of cobalt in the catalyst is 25wt%.

Embodiment 3

[0028] At 35℃, mix 12g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , M A =5800) and 61g polymer surfactant F-127(C 3 H 6 O·C 2 H 4 O) X Dissolve in 3400ml of 2mol / L hydrochloric acid, stir until completely dissolved, then add 283ml of ethyl orthosilicate (TEOS), stir for 24h, then transfer to the polytetrafluoroethylene reactor, crystallize at 120℃ for 24h, filter, After washing, drying at 120°C for 5 hours, and finally calcining at 550°C for 5 hours, a cage-shaped molecular sieve SBA-16 (3) with a pore size of 12 nm was obtained.

[0029] Weigh 10.0g of SBA-16(3) molecular sieve dried at 150℃, and then weigh 16.5g of Co(NO 3 ) 2 ·6H 2 O add water to prepare 9ml solution, immerse the solution on SBA-16(3), dry it, dry it in an oven at 120℃ for 12h to make an intermediate, and weigh 16.5g Co(NO 3 ) 2 ·6H 2 Prepare 9ml of O with water, immerse the solution on the intermediate, dry it, dry it in an oven at 120℃ for 12h, and finally put it in a muffle furnace and ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com