Recycling method of silicon carbide

A recycling method and silicon carbide technology, applied in the field of silicon carbide recycling, can solve problems such as low flash point and toxicity, and achieve the effects of reducing material loss, reducing material waste, and improving the overall recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] One of the recovery methods of silicon carbide of the present invention

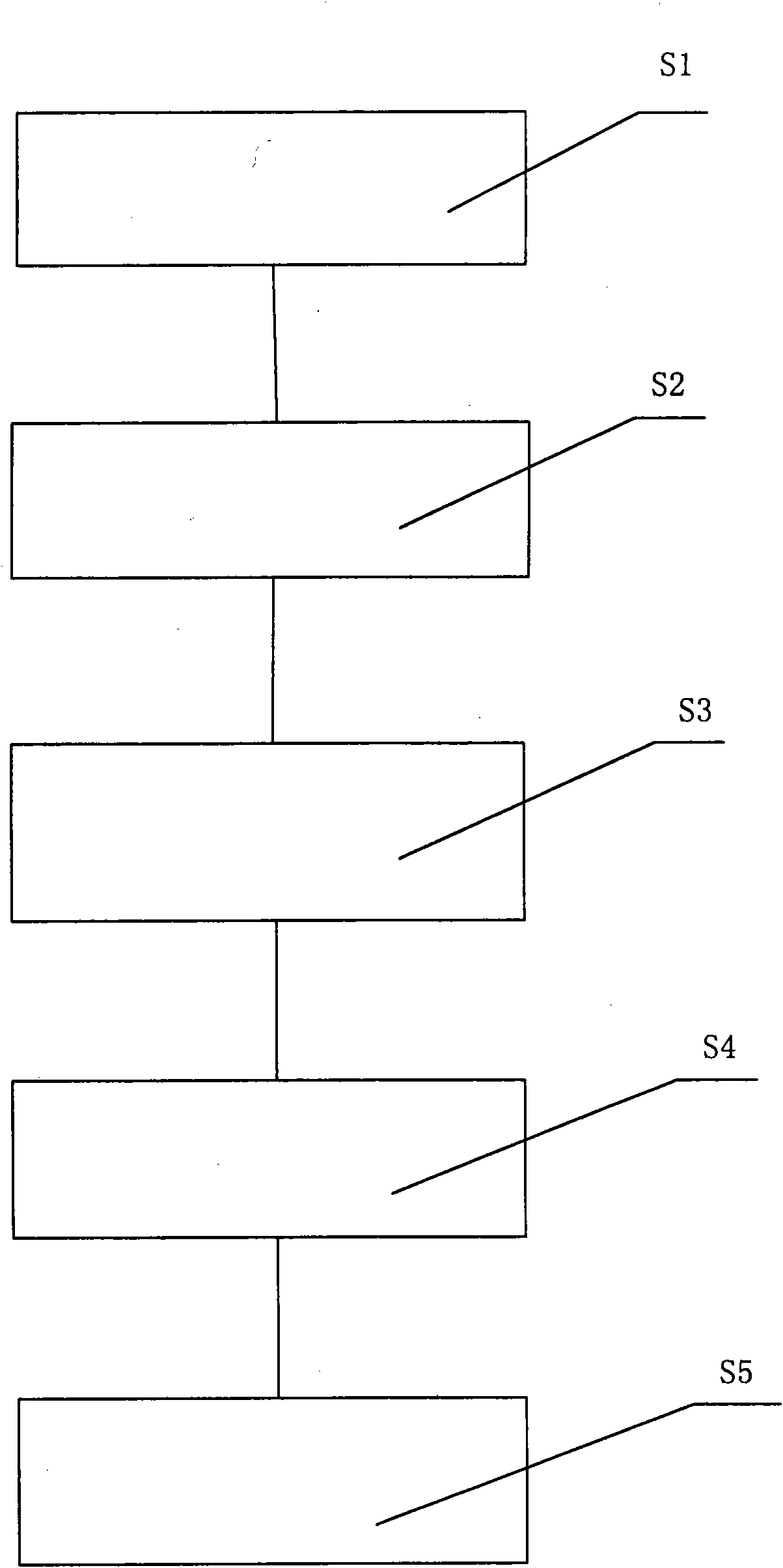

[0055] As shown in Figure 1, the silicon carbide recovery method includes a filtration step S1, a raffinate removal step S2, a pickling and impurity removal step S3, a silicon dissolution step S4, and a lye removal step S5.

[0056] 1. Filtration step S1

[0057] (1) Filtrating the silicon-containing mortar containing silicon carbide, silicon, impurities and dispersion liquid to obtain a silicon carbide / silicon mixture that initially filters out the dispersion liquid;

[0058] In more detail, the silicon-containing mortar is the cutting waste liquid for cutting silicon crystal rods, so the silicon-containing mortar contains silicon carbide, silicon and a dispersion liquid. The dispersion liquid is a commonly used cutting liquid, such as polyethylene glycol ( PEG) and other cutting fluids, silicon-containing mortar may also contain other impurities, such as debris generated by cutting tools, usually...

Embodiment 2

[0073] The recovery method two of silicon carbide of the present invention

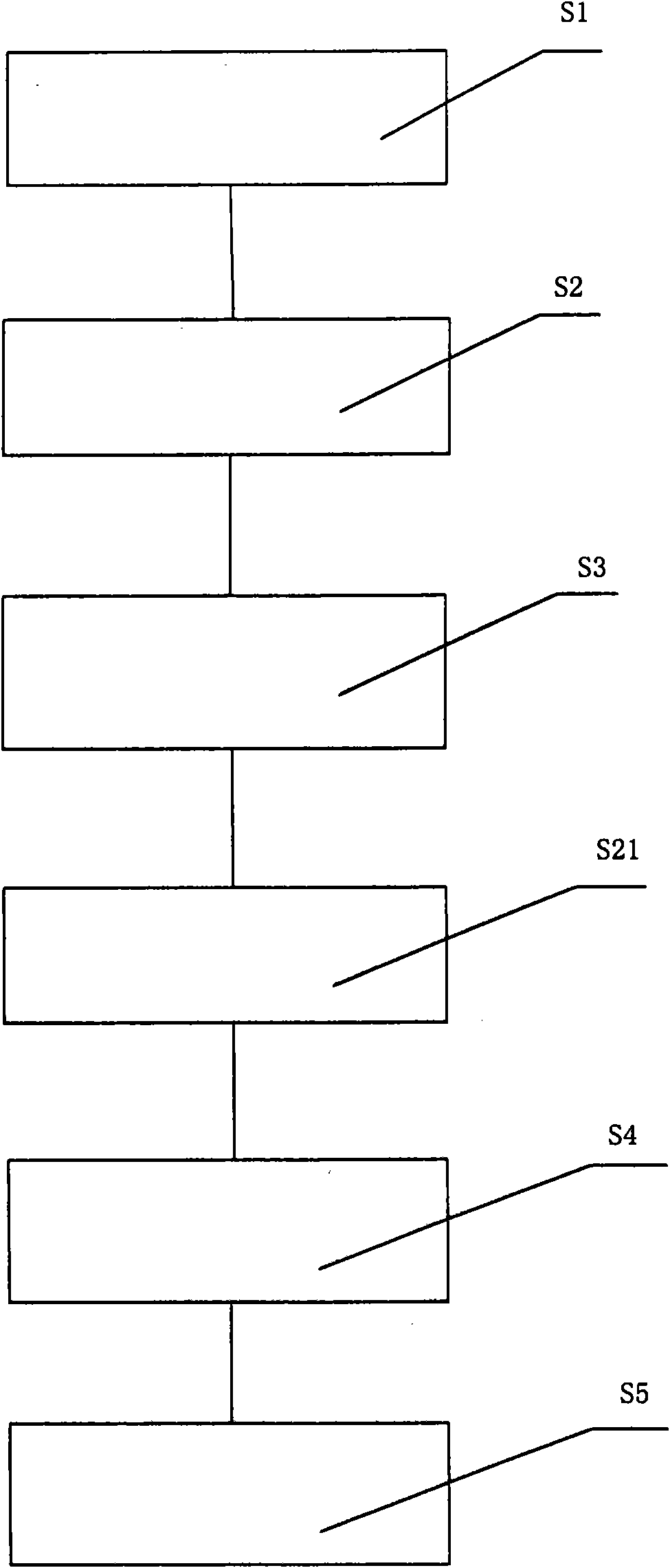

[0074] As shown in Figure 2, the second method of recovering silicon carbide of the present invention includes filtering step S1, raffinate removal step S2, pickling and impurity removal step S3, stirring step S21, silicon dissolution step S4, and lye removal step S5.

[0075] 1. The filtering step S1 is the same as the filtering step S1 described in Example 1.

[0076] 2. The residual liquid removal step S2 is the same as the residual liquid removal step S2 described in Example 1.

[0077] 3. The pickling and impurity removal step S3 is the same as the pickling and impurity removal step S3 described in Example 1.

[0078] 4. Stirring step S21

[0079] Add the impurity-removed silicon carbide / silicon mixture into the aqueous medium of pH 2.5-14, stir evenly and then let it stand to obtain the precipitated silicon carbide / silicon mixture and the liquid medium in which silicon is suspended, and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com