Preparation method of three-dimensional porous zinc oxide microstructure

A three-dimensional porous, micro-structured technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problem of not being an economical method, and achieve the effect of reducing the preparation cost and the preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

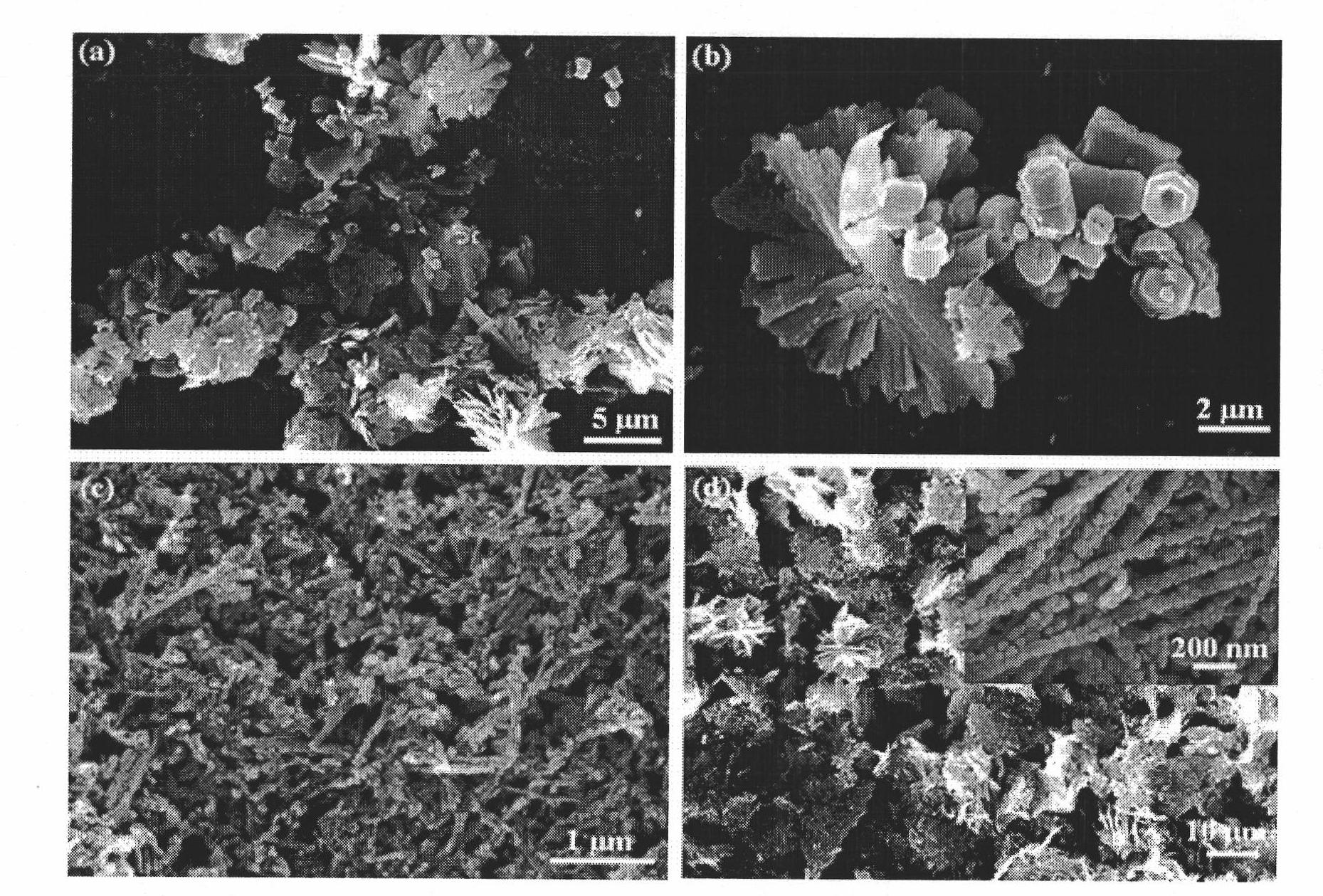

[0016] Example 1, using high-purity water as a solvent, respectively configure 50 mL of 0.1 mol / L zinc acetate solution and 0.2 mol / L urea solution; drip the prepared zinc acetate solution into the urea solution, and keep stirring during this process; The mixture was stirred and refluxed at 60°C for 1.5h to obtain a white precipitate; the white precipitate was filtered and washed with deionized water and absolute ethanol several times, and then dried in a vacuum oven; the dried white precipitate was placed in an air atmosphere Perform annealing treatment, raise the temperature to 300° C. at a rate of 2° C. / min and hold it for 2 hours to obtain a three-dimensional multilayer porous ZnO microstructure.

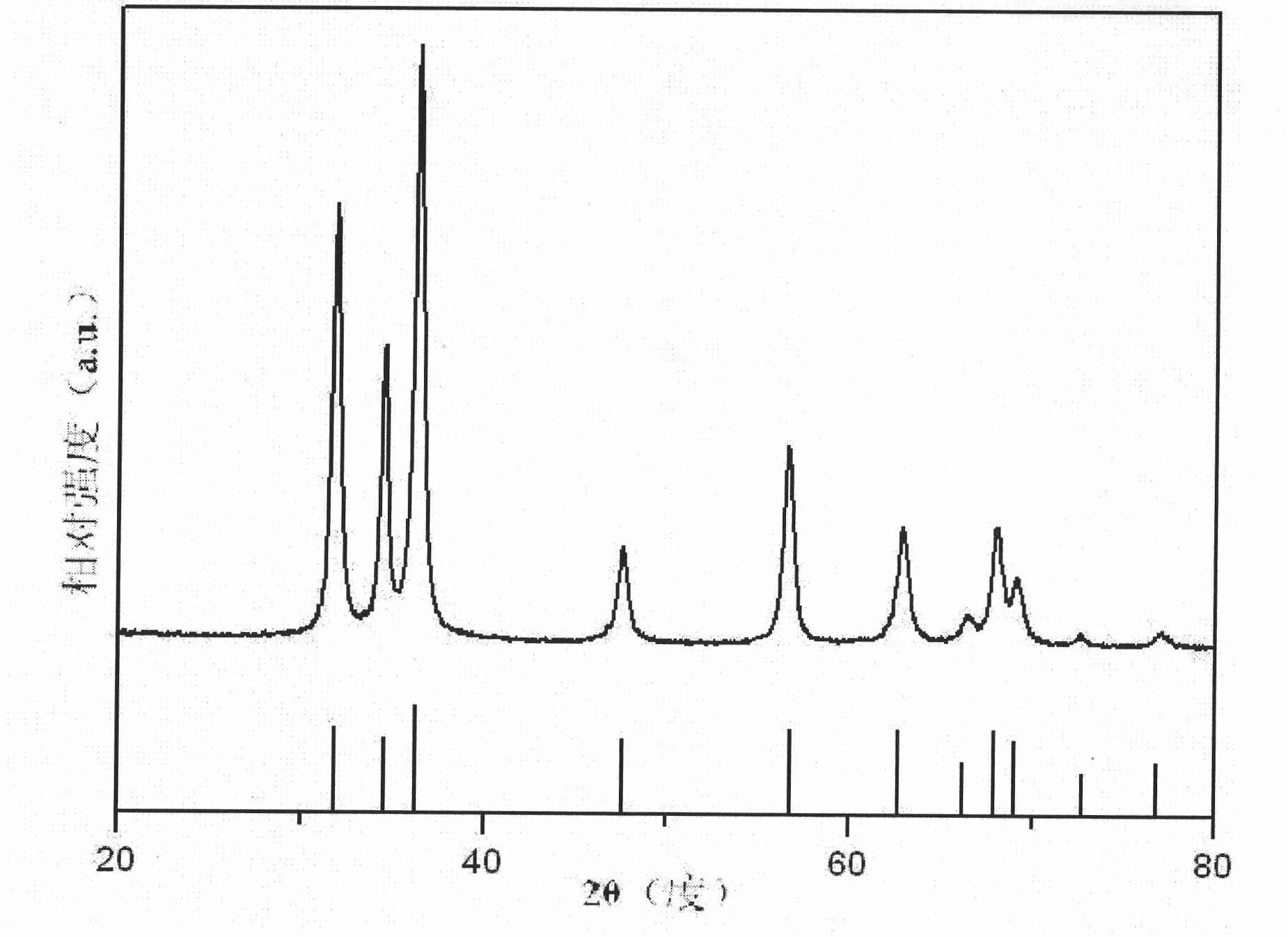

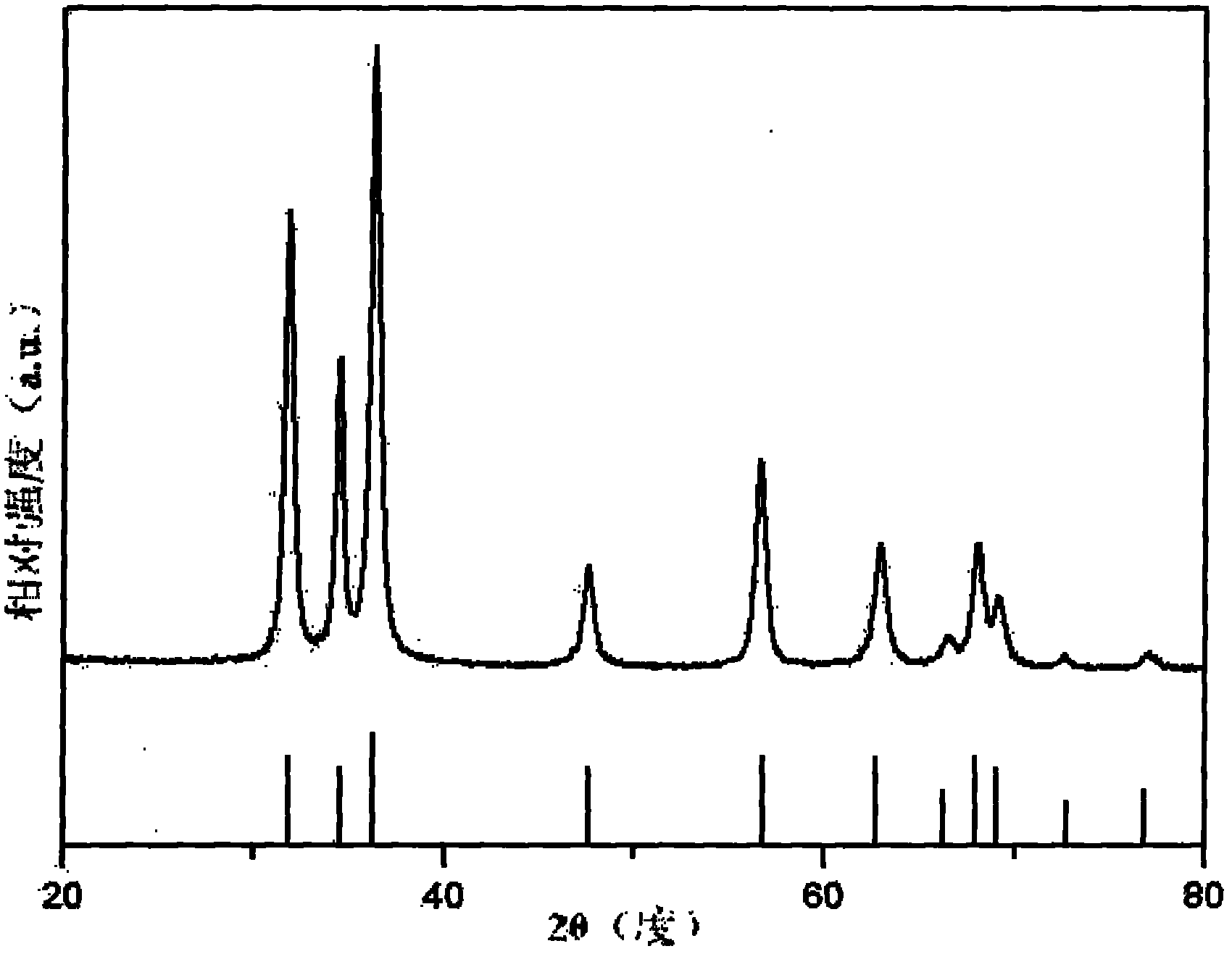

[0017] From figure 1 As can be seen in , the precursor has been completely converted to hexagonal wurtzite ZnO, and no diffraction peaks associated with zinc and carbonaceous nanoparticles appear. According to the Shcerer formula, it can be estimated that the size of ZnO nanopa...

Embodiment 2

[0018] Example 2, using high-purity water as a solvent, configure 0.2mol / L zinc acetate and 0.4mol / L urea solution respectively 50mL; drop the prepared zinc acetate solution into the urea solution, and keep stirring during this process; The mixture was stirred and refluxed at 70°C for 2 hours to obtain a white precipitate; the white precipitate was filtered and washed with deionized water and absolute ethanol several times, and then dried in a vacuum oven; the dried white precipitate was annealed in an air atmosphere For treatment, the temperature was raised to 500° C. at a rate of 3° C. / min and kept at a temperature of 3 hours to obtain a three-dimensional multilayer porous ZnO microstructure.

Embodiment 3

[0019] Example 3, using high-purity water as a solvent, respectively configure 50 mL of 0.3 mol / L zinc acetate solution and 0.8 mol / L urea solution; drip the prepared zinc acetate solution into the urea solution, and keep stirring during this process; The mixture was stirred and refluxed at 80°C for 3 hours to obtain a white precipitate; the white precipitate was filtered and washed with deionized water and absolute ethanol several times, and then dried in a vacuum oven; the dried white precipitate was dried in an air atmosphere After annealing, the temperature was raised to 400° C. at a rate of 3° C. / min and kept at a temperature of 4 hours to obtain a three-dimensional multilayer porous ZnO microstructure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com