Preparation and purification of iodixanol

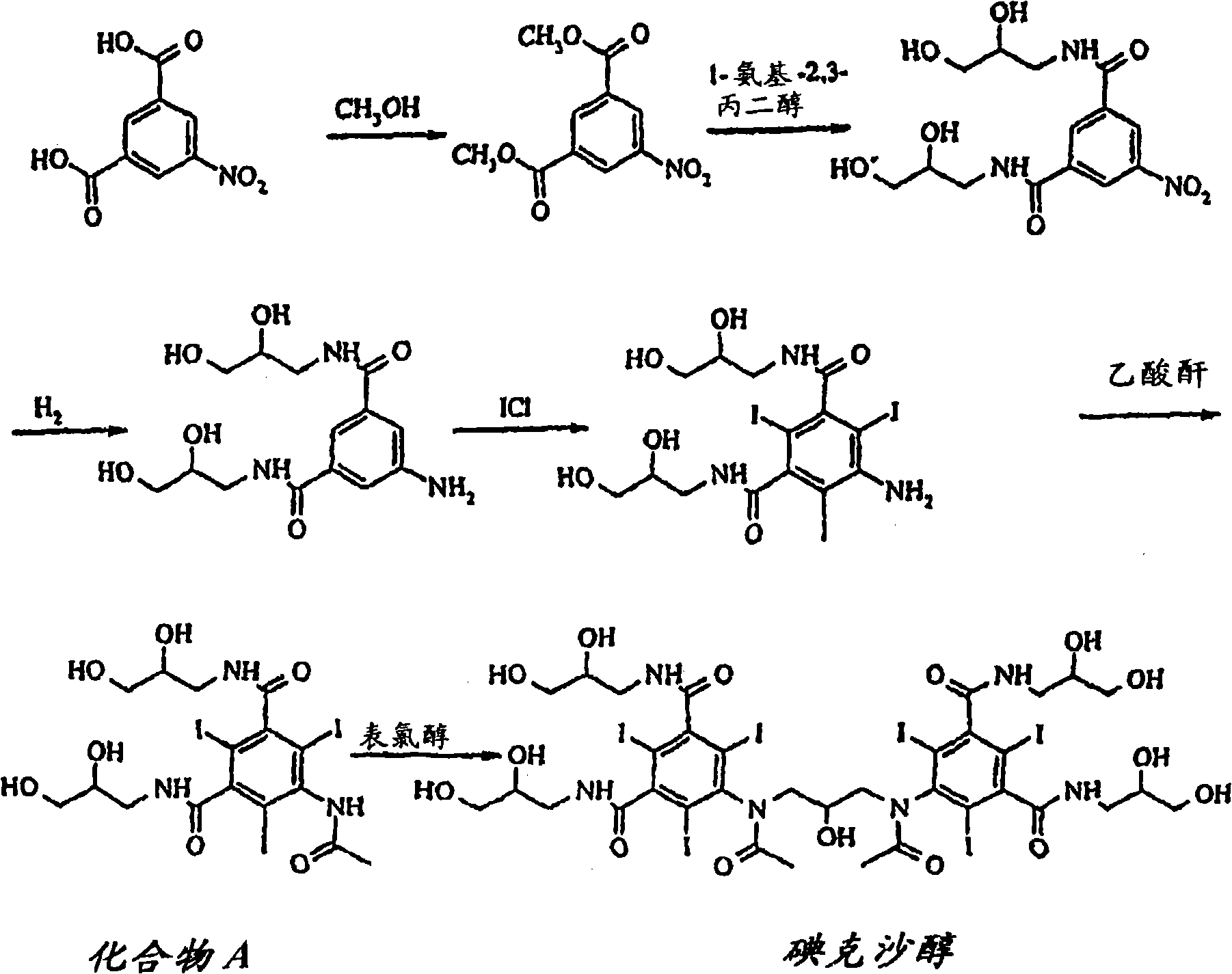

A technology for iodixanol and iohexol is applied in the preparation of organic compounds, preparation of carboxylic acid amides, separation/purification of carboxylic acid amides, etc., and can solve the problems of difficult production, lack of preparation efficiency and economy, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Compound A (1120.5kg, 1.50kmol) was dissolved in an aqueous solution (water 1232.6kg) containing KOH (140.0kg, 2.25kmol) at 20°C, when all solids were dissolved, the temperature dropped below 20°C, and boric acid was added evenly in portions (64.9kg, 1.05kmol), then added dropwise hydrochloric acid (30.4kg, 0.30kmol), and then added dropwise epichlorohydrin (83.3kg, 0.90kmol). The pH during the reaction was 10-11. When the HPLC monitors that the compound A≤5, the reaction is completed, water (1232.6 kg) is added, the pH value is adjusted to 5-6 with 18% hydrochloric acid, and the activated carbon is decolorized.

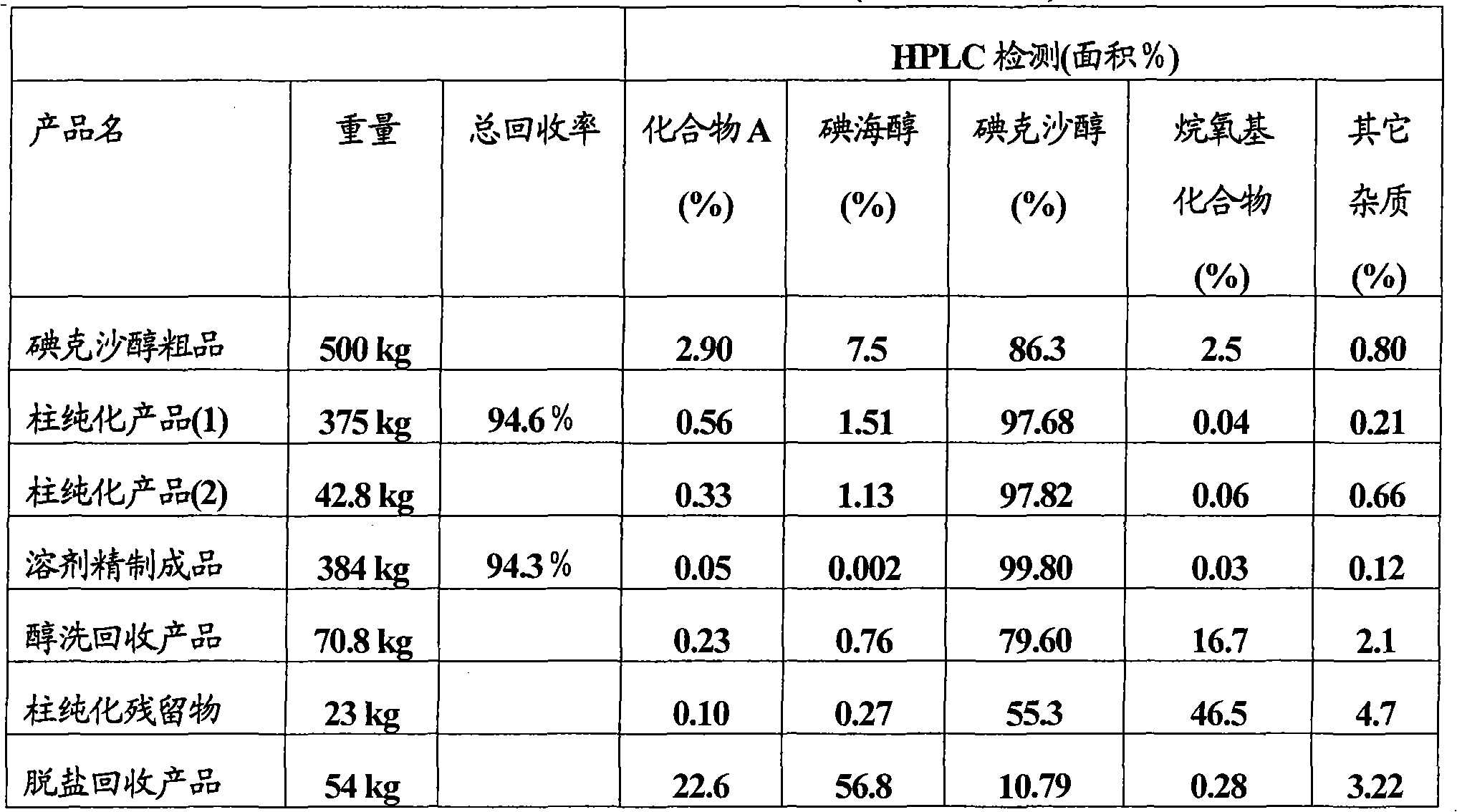

[0089] According to HPLC analysis, the filtrate contained 86.3% iodixanol, 7.5% iohexol, 2.9% compound A, 2.7% alkoxy compounds and other minor impurities.

Embodiment 2

[0091] Compound A (1120.5kg, 1.50kmol) was dissolved in an aqueous solution (1232.6kg) containing NaOH (78.0kg, 1.95kmol) at 20°C. After all the solids were dissolved, the temperature dropped below 20°C, and boric acid ( 51.0kg, 0.83kmol), then hydrochloric acid (23.3kg, 0.23kmol) was added dropwise, and then epichlorohydrin (83.3kg, 0.90kmol) was added dropwise. The pH during the reaction was 10-11. When HPLC monitors compound A≤5, the reaction ends, add water (1232.6kg), adjust the pH value to 5-6 with 18% hydrochloric acid, remove inorganic ions with anion and cation exchange resins, decolorize with activated carbon, evaporate to dryness, and obtain iodine Kexanol crude product 1163.0kg.

[0092] According to HPLC analysis, it contained 85.0% iodixanol, 7.1% iohexol, 3.0% compound A, 2.9% alkoxy compounds and other minor impurities.

Embodiment 3

[0094] Compound A (11.2kg, 15.0mol) was dissolved in 2-methoxyethanol solution (12.3kg) containing NaOH (0.96kg, 24.0mol) at 20°C, when all solids were dissolved, the temperature dropped below 20°C, Boric acid (0.65kg, 10.5mol) was uniformly added in portions, then hydrochloric acid (0.55kg, 5.4mol) was added dropwise, and then epichlorohydrin (0.75kg, 8.1mol) was added dropwise. The pH during the reaction was 10-11. When the HPLC monitors that the compound A≤5, the reaction is completed, water (12.3 kg) is added, the pH value is adjusted to 5-6 with 18% hydrochloric acid, and the activated carbon is decolorized.

[0095] According to HPLC analysis, the filtrate contained 84.2% iodixanol, 5.1% iohexol, 4.8% compound A, 2.5% alkoxy compounds and other minor impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com