Photosensitive resin composition and preparation method thereof

A technology of photosensitive resin and composition, applied in optomechanical equipment, photosensitive materials for optomechanical equipment, optics, etc., can solve the problems of low utilization rate of ultraviolet light and high exposure energy of ultraviolet light, and achieve the improvement of utilization rate and reduction of Exposure energy, the effect of reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

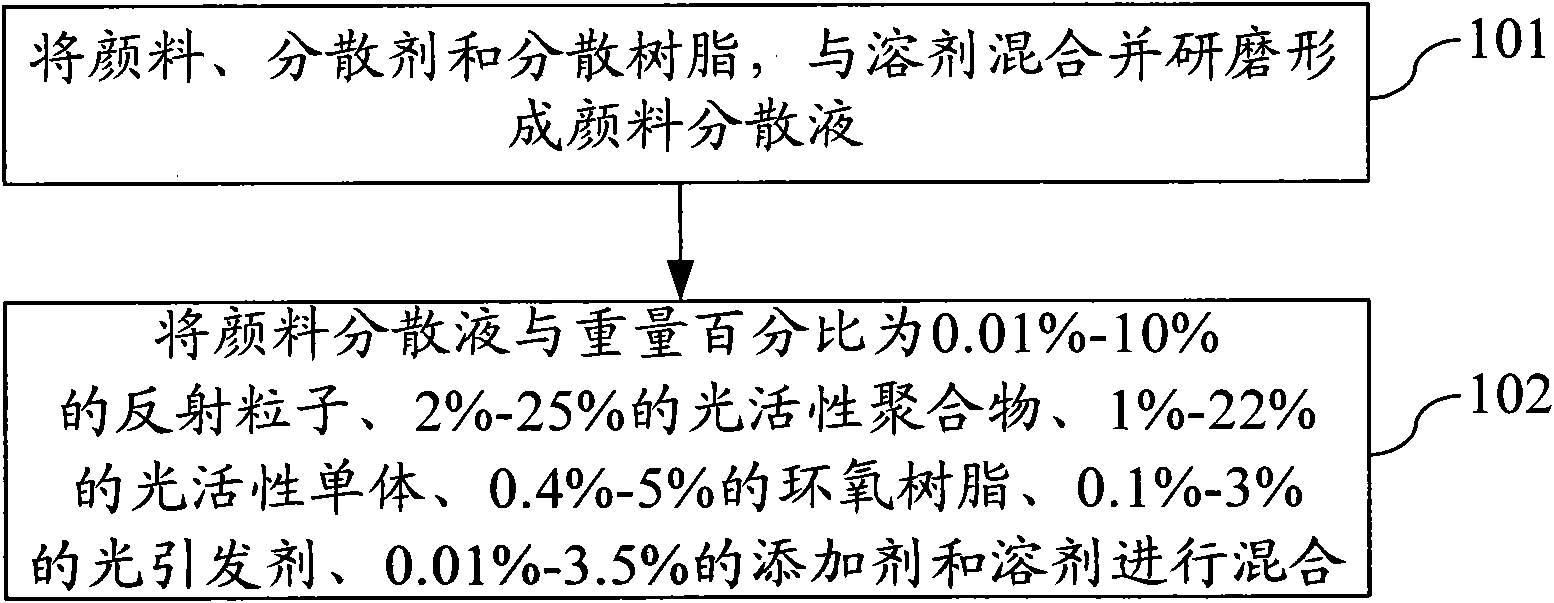

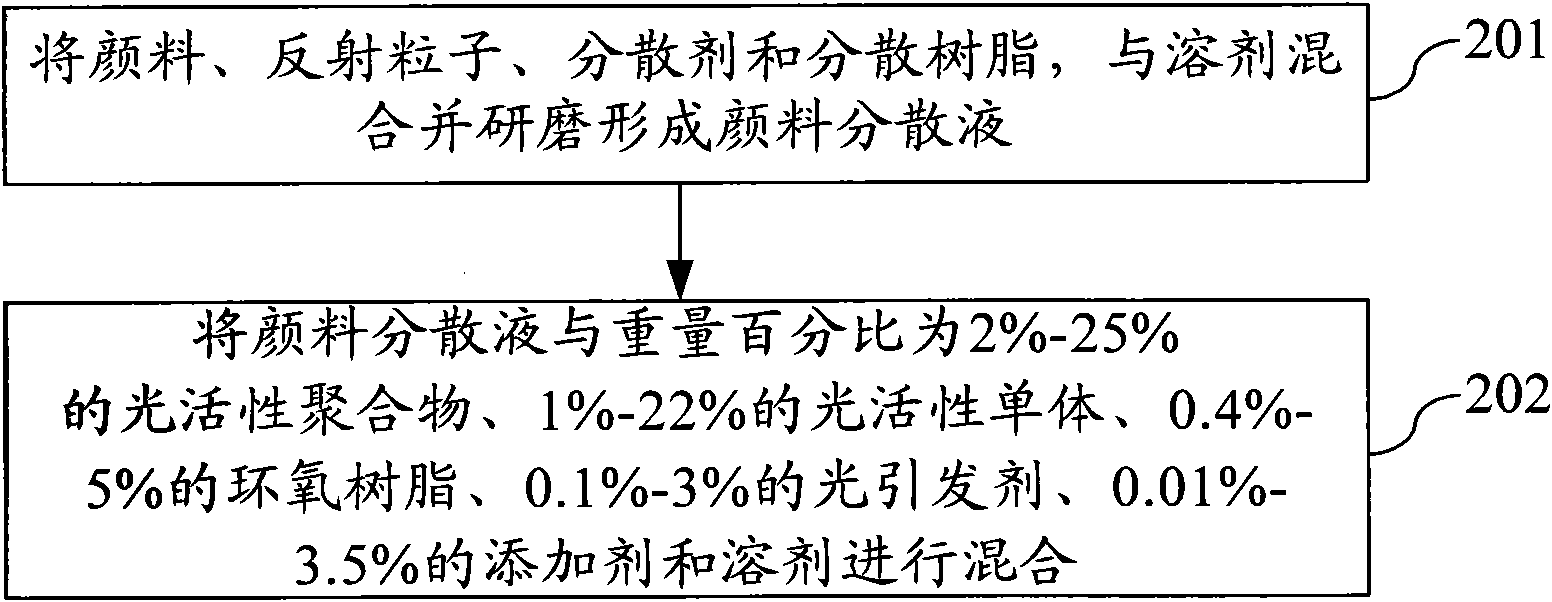

Method used

Image

Examples

Embodiment 2

[0050] The components of the photosensitive resin composition of this embodiment refer to the data of Example 2 in Table 1, specifically: 6% of pigment, 2.5% of dispersant, 2% of dispersed resin, 1% of reflective particles, 67.4% of solvent, photoactive polymerization 10% of compound, 8% of photoactive monomer, 2.5% of epoxy resin, 0.45% of photoinitiator, and 0.15% of additive, wherein the above percentages are all percentages by weight.

Embodiment 3

[0052] The components of the photosensitive resin composition of this embodiment refer to the data of Example 3 in Table 1, specifically: 8% of pigment, 4% of dispersant, 2.4% of dispersed resin, 1.5% of reflective particles, 60.07% of solvent, photoactive polymerization 12% of compound, 8% of photoactive monomer, 1.8% of epoxy resin, 2% of photoinitiator, and 0.23% of additive, wherein the above-mentioned percentages are all percentages by weight.

[0053] Embodiment 4 of the photosensitive resin composition of the present invention

[0054] The components of the photosensitive resin composition of this embodiment refer to the data of Example 4 in Table 1, specifically: 8% of pigment, 4% of dispersant, 2.4% of dispersed resin, 2% of reflective particles, 55.65% of solvent, photoactive polymerization 15% of compound, 8% of photoactive monomer, 2.5% of epoxy resin, 2% of photoinitiator, 0.45% of additive, wherein the above-mentioned percentages are all percentages by weight.

...

Embodiment 7

[0093] The content of pigment in the photosensitive resin composition of embodiment 7 and embodiment 8 is greater than the content of pigment in embodiment 5 and embodiment 6, but because the content of reflective particles in embodiment 7 and embodiment 8 is much greater than embodiment 5 and embodiment The content of reflective particles in Example 6, so the ultraviolet light exposure energy required by the photosensitive resin composition of Example 7 and Example 8 is less than that required by Example 5 and Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com