Speed control system and method of titanium welded pipe production line

A speed control, production line technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of actual speed difference of line speed units, reduce production efficiency, unqualified titanium tube, etc., achieve consistent speed, reduce errors, and avoid superficial The effect of indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

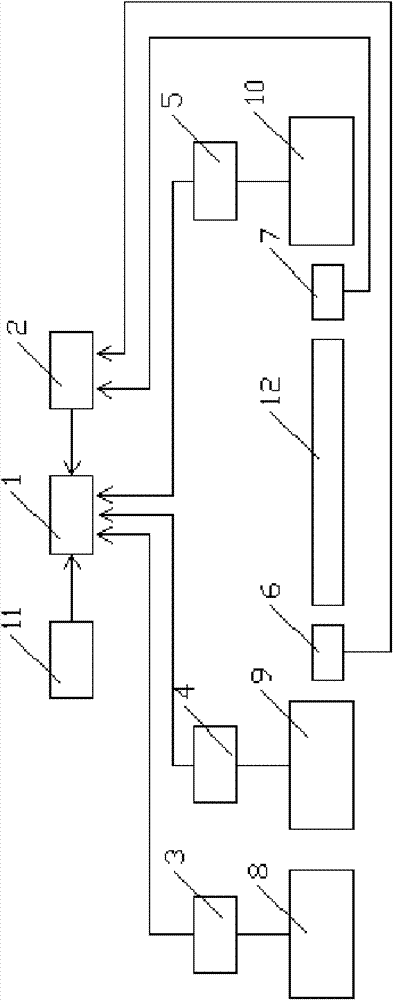

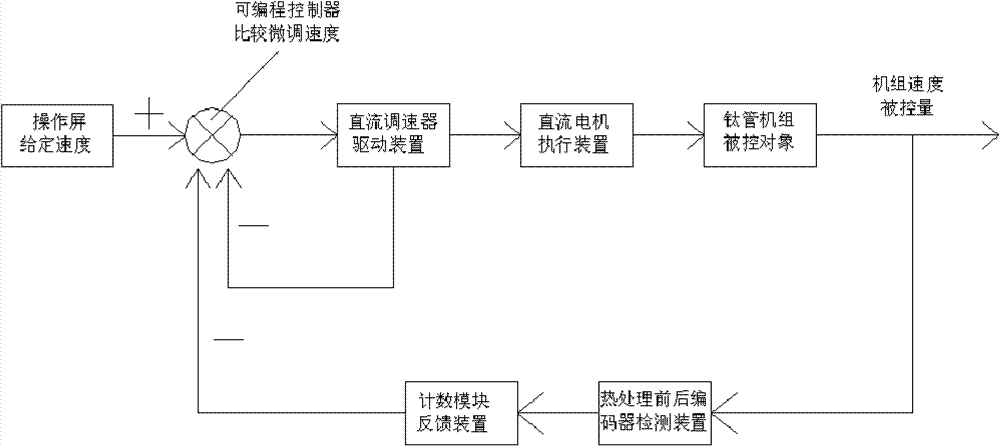

[0021] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a speed control system for a titanium welded pipe production line includes a programmable controller 1, a counting module 2, a DC speed controller 3 for a forming unit, a DC speed controller 4 for a sizing unit, a DC speed controller 5 for a pulling unit, and an operation Screen 11, the programmable controller 1 is respectively connected with the DC speed governor 3 of the forming unit, the DC speed governor 4 of the sizing unit, the DC speed governor 5 of the pulling unit and the operation panel 11 through the Profibus DP bus network; The counting module 2 described above is respectively connected with the encoder 6 before heat treatment and the encoder 7 after heat treatment, the encoder 6 before heat treatment is located between the sizing unit 9 and the heat treatment equipment 12, the encoder 7 after heat treatment is located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com