Intermittent energy-saving wire winding system of copper upcasting continuous casting machine

A continuous casting machine and intermittent technology, which is applied in the field of intermittent energy-saving winding system of copper upward leading continuous casting machine, can solve the problems of bending damage of casting copper materials, large traction force of copper materials, and low automation level, etc. Achieve the effect of avoiding surface indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

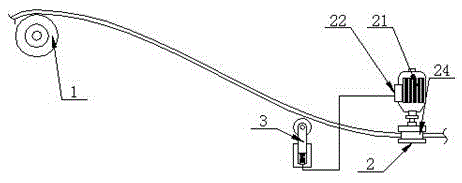

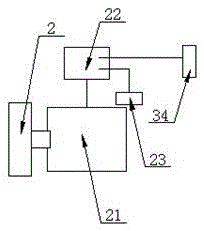

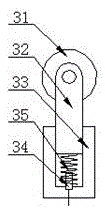

[0015] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0016] Such as Figure 1 to Figure 3 As shown in the figure, an intermittent energy-saving winding system for continuous casting machine with copper materials, including the top traction guide wheel 1 of the continuous casting machine and the winding push wheel 2 of the continuous casting machine, the height of the traction guide wheel 1 at the top of the continuous casting machine is Higher than the winding push wheel 2 of the continuous casting machine, and the axis of the traction guide wheel 1 on the top layer of the continuous casting machine is set horizontally, the axis of the winding pushing wheel 2 of the continuous casting machine is vertically set, and the continuous casting machine The winding push wheel 2 is coaxially provided with a continuous casting machine winding driving motor 21 that drives the continuous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com