Oily solid-form cosmetic

A solid-state, cosmetic technology, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as poor compatibility, reduced viscosity of preparations, thickening effect or insufficient gelling ability, etc., to achieve less sticky feeling, The effect of excellent finger pick-up or spreading, and excellent moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

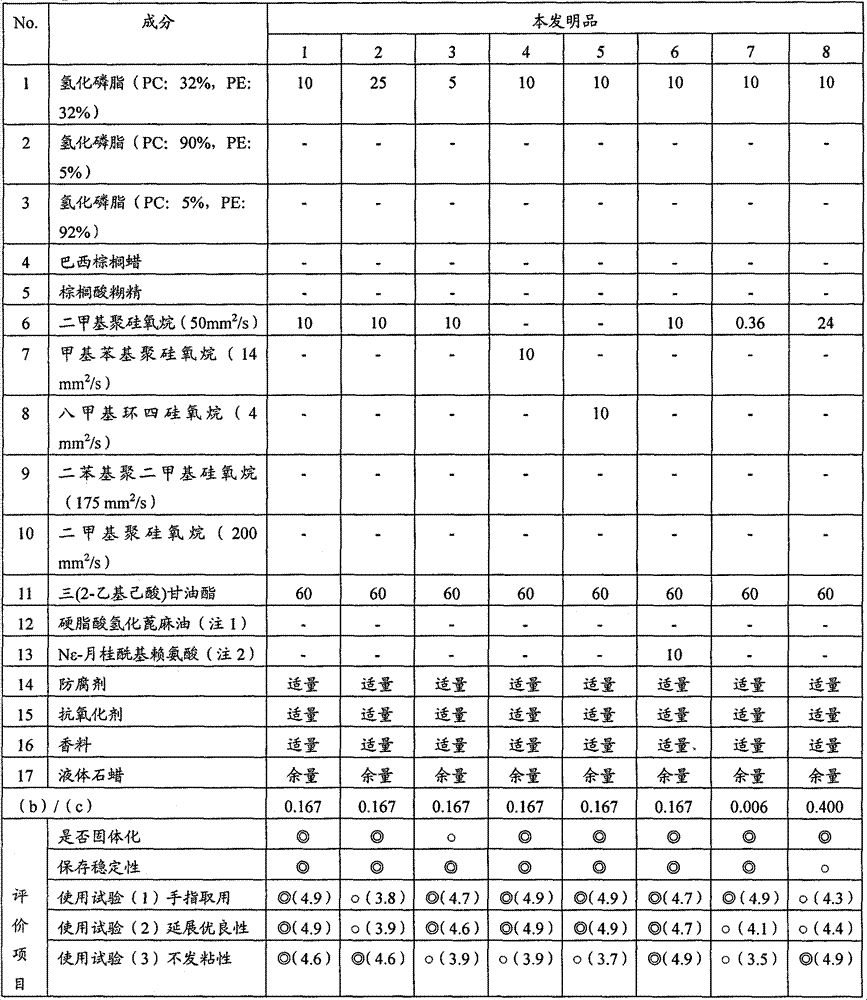

[0054] Invention products 1-8 and comparative products 1-11: solid paste

[0055] Prepare a solid paste according to the composition shown in Table 1 and Table 2 and the following production method. As an evaluation of the feeling of use, sensory evaluations were performed by panelists on (1) finger pick-up, (2) spreadability, and (3) non-stickiness. The storage stability of the solid paste was left to stand in a thermostat at 50° C. for one month, and changes in appearance (separation, drainage) were evaluated with the naked eye. The results are shown in Table 1 and Table 2 together.

[0056] [Table 1]

[0057]

[0058] The kinematic viscosities of components No. 6 to 10 are values at 25°C.

[0059] (Note 1) Castolide MS (manufactured by National Misatsu Corporation)

[0060] (Note 2) Amihope LL (manufactured by Ajinomoto Co., Ltd.)

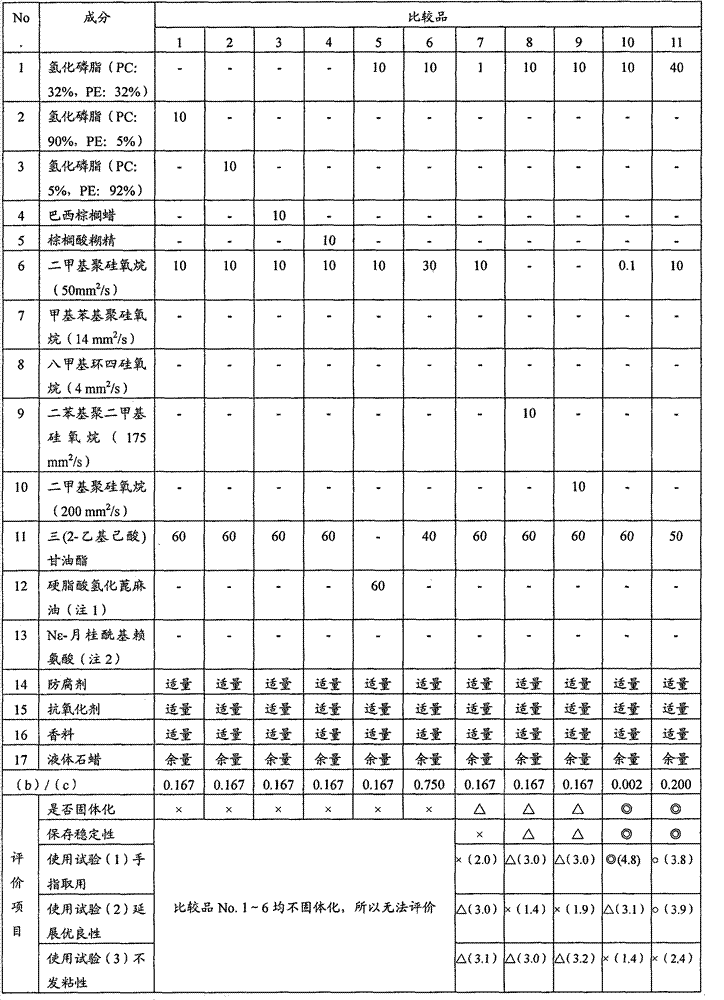

[0061] [Table 2]

[0062]

[0063] The kinematic viscosities of components No. 6 to 10 are values at 25°C.

[0064] (Note 1)...

Embodiment 2

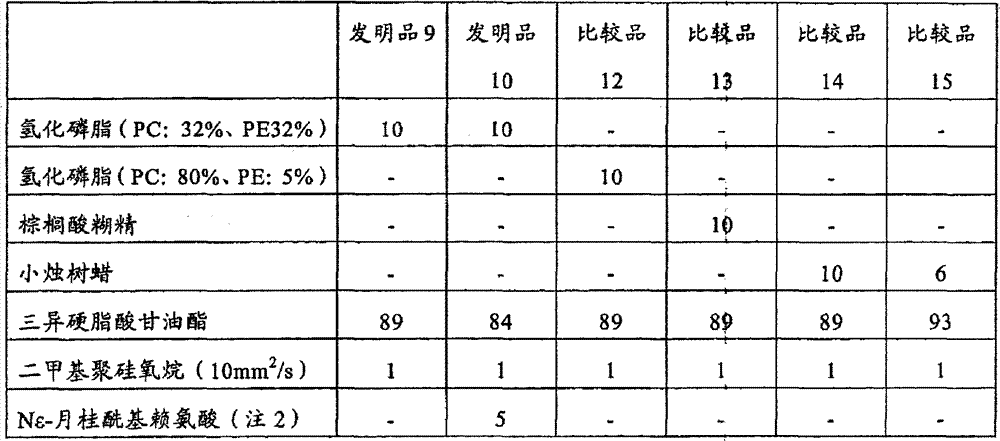

[0110] Invention products 9-10 and comparative products 12-15: solid paste

[0111] A solid paste was prepared according to the composition shown in Table 3 and the following production method. The water permeation rate and shear stress of the obtained solid paste were measured, and sensory evaluation ((a) spreading, (b) tingling feeling after application, (c) moisturizing effect) was performed.

[0112] [table 3]

[0113]

[0114] (Manufacturing method)

[0115] A: Heat the ingredients to 80°C.

[0116] B: Mix and stir A with a disperser mixer.

[0117] C: B (80° C.) was filled in a container, cooled to room temperature, and a solid paste was obtained.

[0118] (Moisture evaporation rate test)

[0119] The occlusive properties of the solid pastes of Invention Product 9 and Comparative Products 12 to 14 were examined. This solid paste was uniformly coated on the polyvinylidene chloride membrane of a Franz-type diffusion cell with a 0.9% NaCl aqueous solution using a...

Embodiment 3

[0150] Embodiment 3: solid massaging material

[0151] The solid massaging material of the following prescription was prepared by the following manufacturing method.

[0152]

[0153] 4. Ethyl oleate 0.1

[0154] 5. Glyceryl tri-2-ethylhexanoate 32.0

[0155] 6. Nylon powder 7.0

[0156] 7. Nε-lauroyl lysine (Note 2) 8.0

[0157] 8. The balance of liquid paraffin

[0158] 9. Antioxidant 0.1

[0159] 10. Appropriate amount of preservatives

[0160]11. Appropriate amount of spices

[0161] (Note 3) Phospholipid composition PC: 28%, PE: 28%

[0162] (Note 4) Kinematic viscosity 20mm 2 / s(25℃)

[0163] (Production method)

[0164] A: Components (1) to (11) were heated to 80°C.

[0165] B: Mix and stir with a disperser mixer.

[0166] C: B (80 degreeC) was filled in the container, it cooled to room temperature, and the solid massaging material was obtained.

[0167] The solid massaging material of Example 3 has a penetration load value of 120 g at 35° C., and is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com