Method for preparing tea polyphenol rich in methylated catechin

A technology of methylated catechin tea and methylated catechin, which is applied in the direction of organic chemistry, can solve the problems of many by-products, poor specificity, unsuitable, etc., and achieve good regeneration performance, environmental friendliness, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

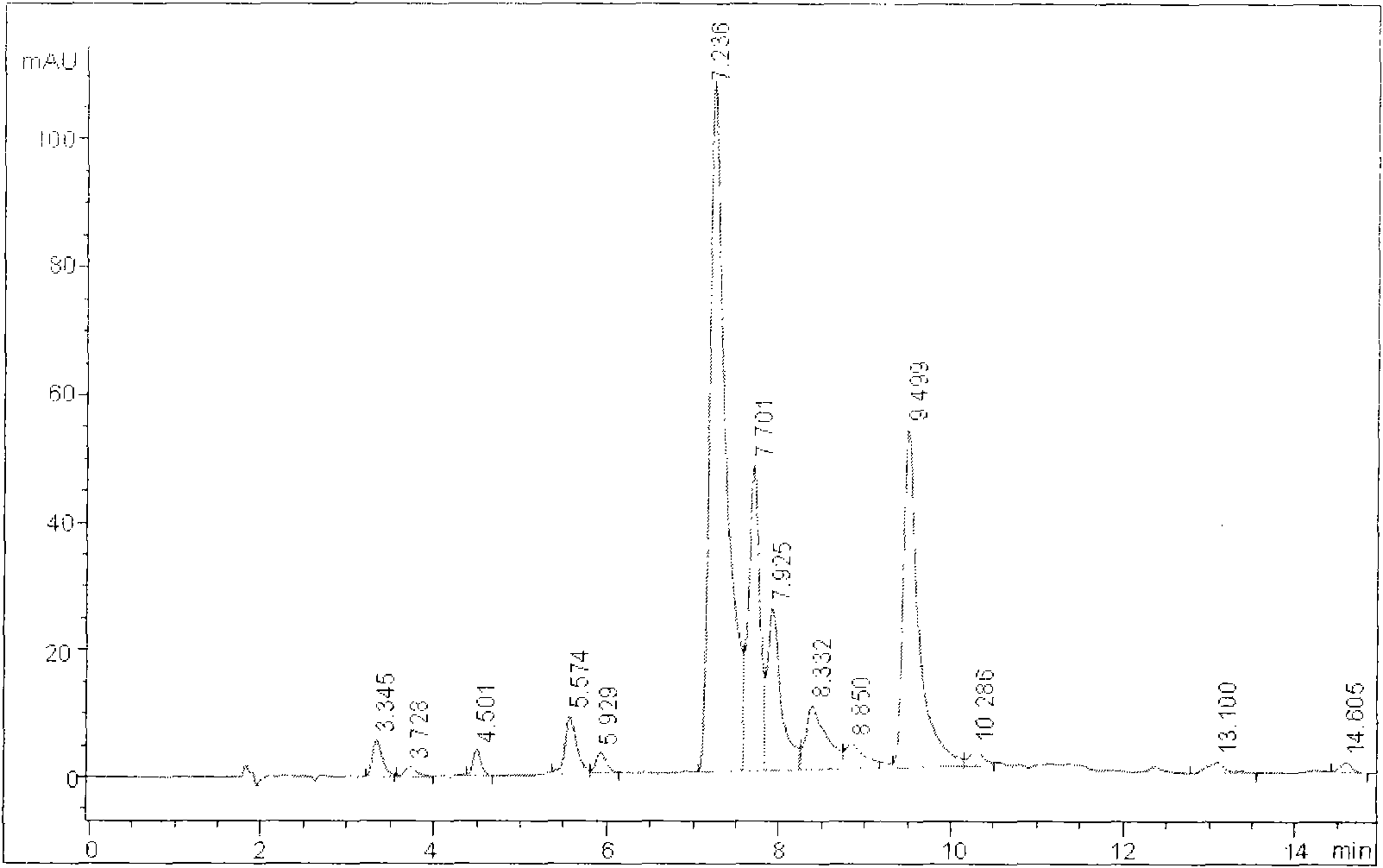

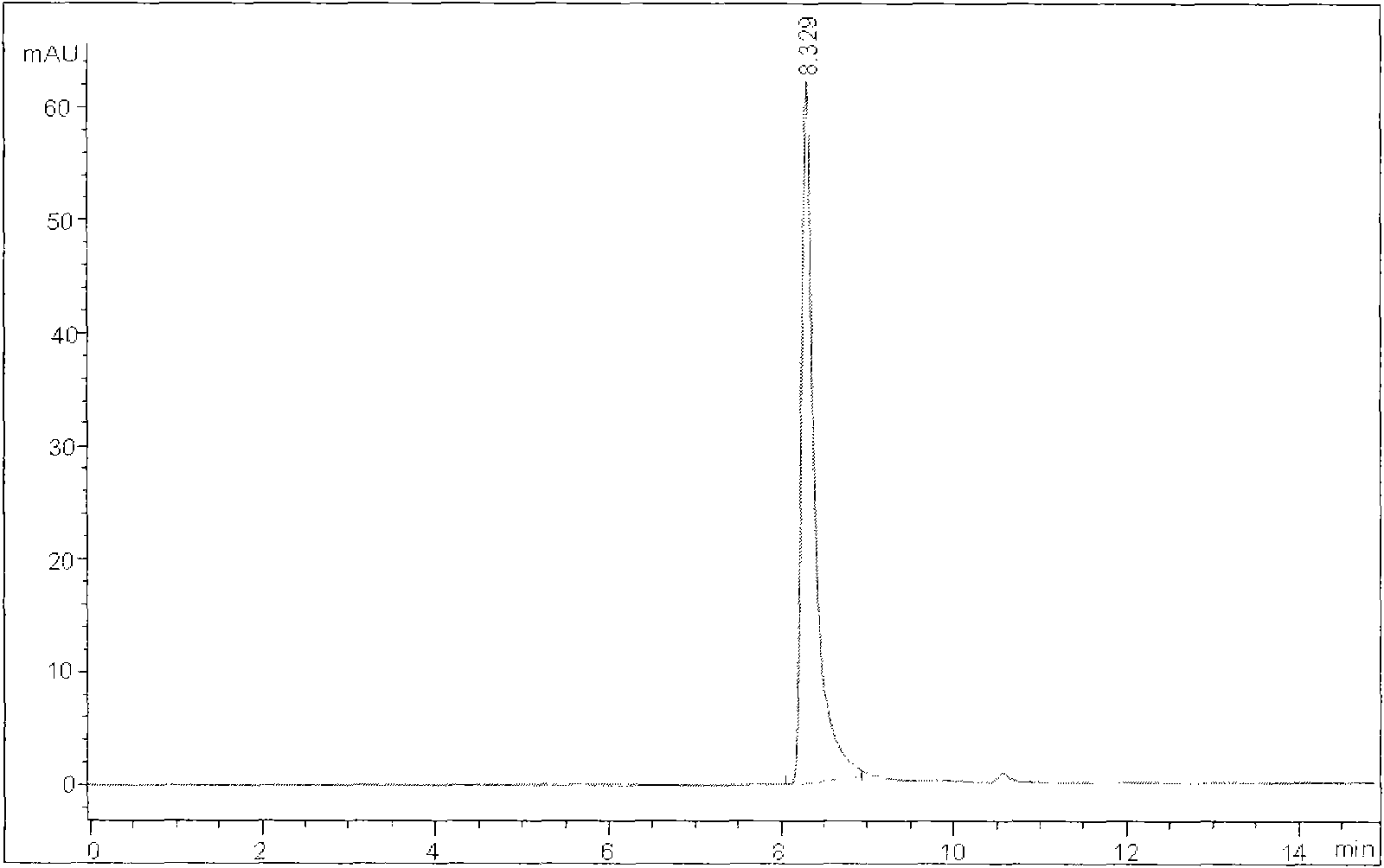

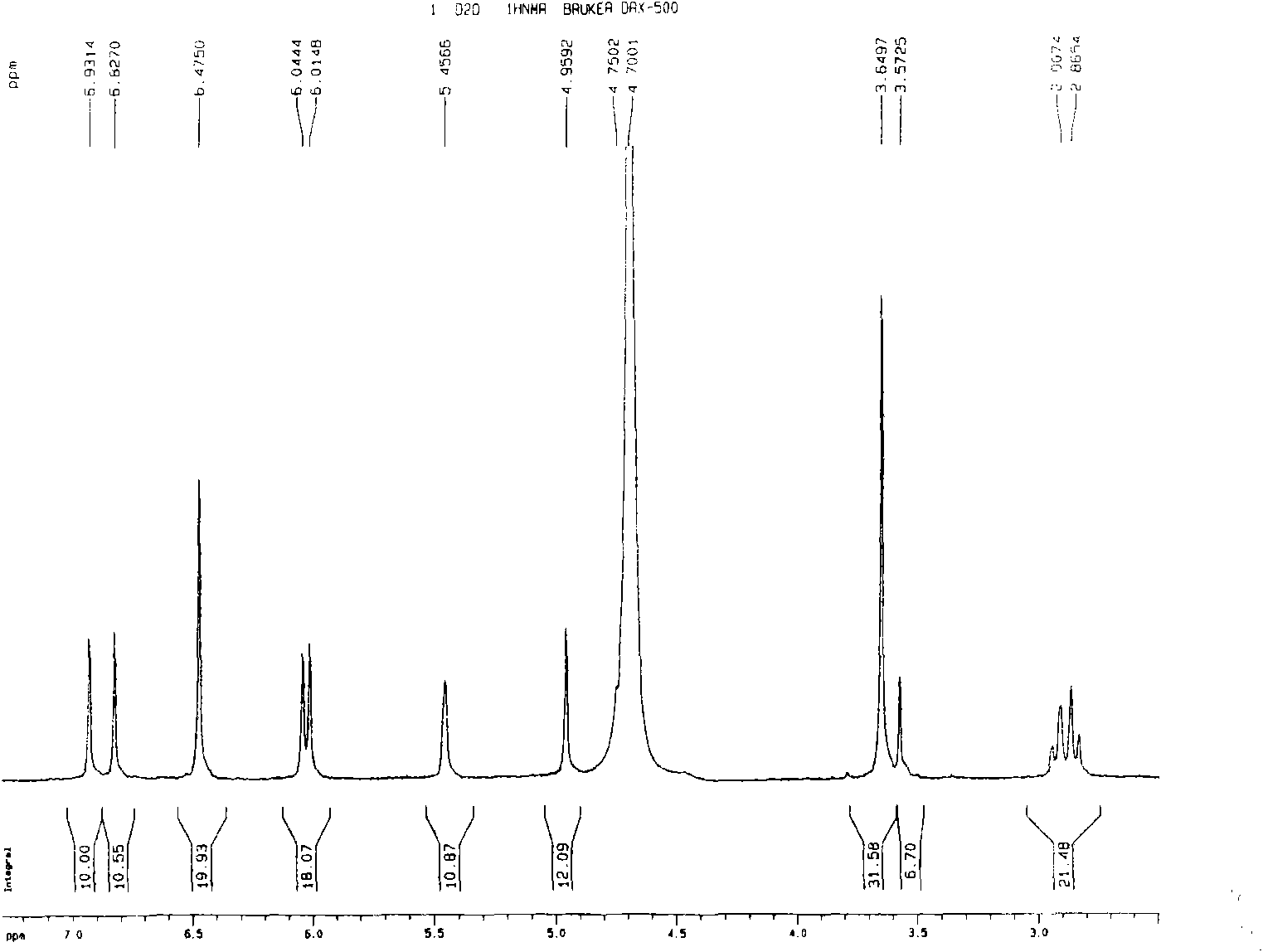

Image

Examples

Embodiment Construction

[0018] 1) Crude tea polyphenols extract: tea leaves were extracted in a hot water bath for 30 minutes, the ratio of solid to liquid was 1:20, the temperature of the water bath was 80°C, and concentrated under reduced pressure at 40°C after extraction;

[0019] 2) Macroporous resin A treatment: select macroporous resin A, balance it with pH3.0 buffer, adjust the sample solution to the same pH, fully elute with water after sample loading, and the elution flow rate of water is 2 per hour column bed volume;

[0020] 3) Tea polyphenol component I rich in methylated catechins: use 80% ethanol solution to elute the macroporous resin A, the flow rate is 1 column bed volume per hour, collect the eluate, and store it at 50° C. Concentrate under reduced pressure;

[0021] 4) Toyopearl HW-40S resin treatment: select Toyopearl HW-40S resin, use 40% concentration of ethanol solution to elute the resin after loading the tea polyphenol component I rich in methylated catechins, and the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com