Temperature sensing medium for all-liquid type temperature meter and filling method thereof

A thermometer and medium technology, applied in thermometers, thermometers based on material expansion/contraction, measuring devices, etc., can solve the problems of low flash point, chronic leakage, corrosion of parts, etc., and achieve non-volatile and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

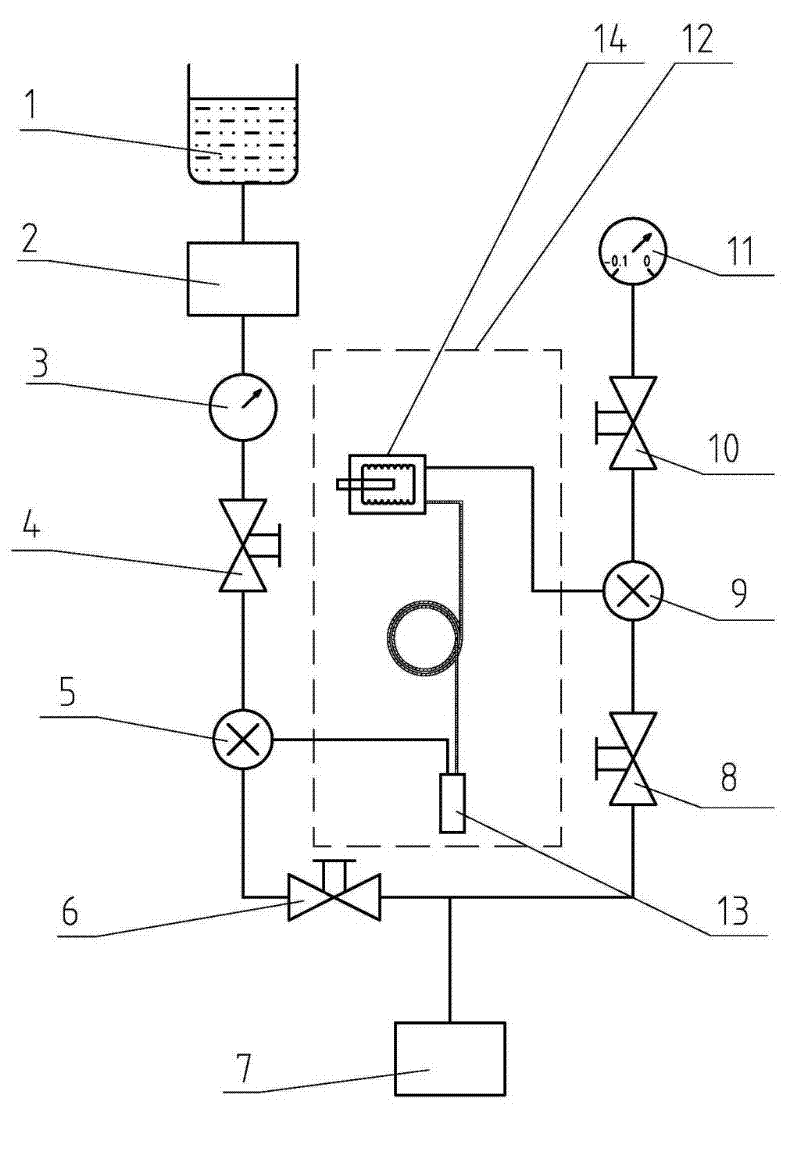

Image

Examples

Embodiment 1

[0018] Add a mixture of octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM) at a molar ratio of 1:1, add 3% concentrated sulfuric acid of the total mass of the material as a catalyst, and heat at 30°C After stirring for 3 hours, add distilled water and stir for 30 minutes, raise the temperature to 65°C, continue stirring for 30 minutes, keep the layers, take the oil layer, neutralize the residual sulfuric acid with 6% sodium carbonate aqueous solution, wash with water until neutral, and filter Remove low boilers, decolorize with activated carbon after cooling, and obtain colorless and transparent liquid silicone oil. The amount of activated carbon added is 3% of the total mass of the oil layer.

Embodiment 2

[0020] Add a mixture of octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM) at a molar ratio of 1:2, and add concentrated sulfuric acid with 5% of the total mass of the material as a catalyst. After stirring for 3 hours, add distilled water and stir for 30 minutes, raise the temperature to 70°C and continue to stir for 30 minutes, then separate the layers, take the oil layer, neutralize the residual sulfuric acid with 5% sodium carbonate aqueous solution, wash with water until neutral, and filter Remove low boilers, decolorize with activated carbon after cooling, and obtain colorless and transparent liquid silicone oil. The amount of activated carbon added is 2% of the total mass of the oil layer.

Embodiment 3

[0022] Add a mixture of octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM) at a molar ratio of 1:1, and add concentrated sulfuric acid with 4% of the total mass of the material as a catalyst. After stirring for 3 hours, add distilled water and stir for 30 minutes, raise the temperature to 70°C and continue to stir for 30 minutes, then separate the layers, take the oil layer, neutralize the residual sulfuric acid with 5% sodium carbonate aqueous solution, wash with water until neutral, and filter Remove low boilers, decolorize with activated carbon after cooling, and obtain colorless and transparent liquid silicone oil. The amount of activated carbon added is 2% of the total mass of the oil layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com