Method for improving photoetching critical dimension in groove process

A trench and lithography technology, applied in the photoengraving process, optics, optomechanical equipment and other directions of the pattern surface, which can solve the problems of BARC thickness and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

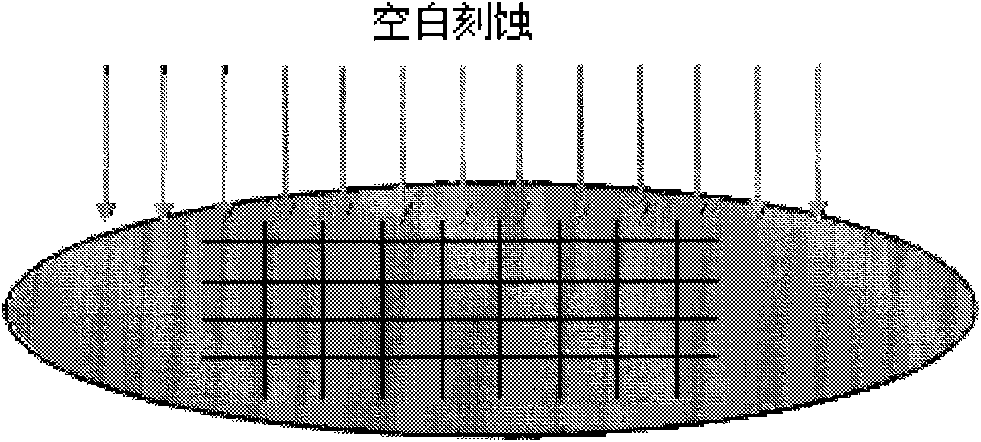

[0014] In an embodiment of the present invention, the method for improving the critical dimension of photolithography in the trench process is to planarize the silicon wafer with steps after the trench is formed and before the photoresist is coated. These include a photolithography and a BARC spin coating. Specifically include the following steps:

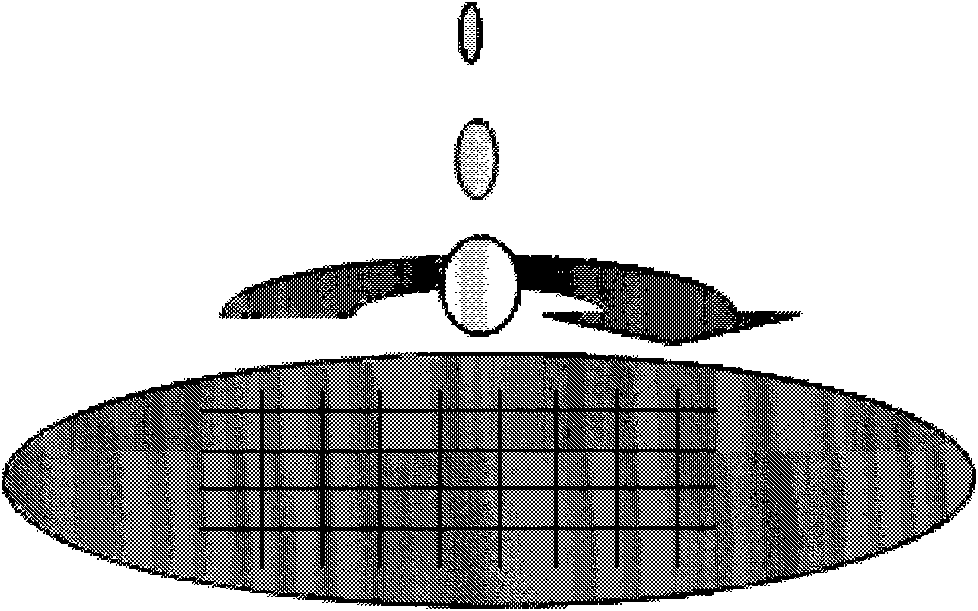

[0015] Step one, combine Figure 7 As shown, the negative photoresist was spin-coated and baked. Spin-coat negative-tone photoresist on the surface of the trench and silicon wafer, and then bake. The negative photoresist refers to a photoresist whose polarity is opposite to that of traditional trench lithography. If negative resist is used in trench lithography, positive resist is spin-coated, and so on. The negative photoresist can be G-line, I-line, KrF, ArF or even a photoresist suitable for shorter wavelengths, and its thickness is not limited.

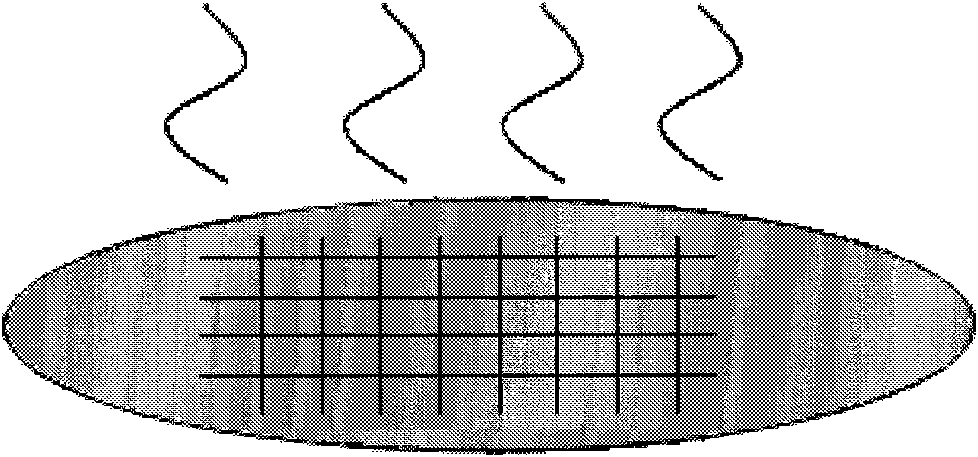

[0016] Step two, combine Figure 8 As shown, use the mask plate with the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com