Preparation method and catalysis application of acidic-basic functionalized mesoporous material by using solid-state ionic migration method

A mesoporous material and ion migration technology, which is applied in molecular sieve catalysts, organic carbonate preparation, physical/chemical process catalysts, etc., can solve the problems of difficult to meet raw material requirements and relatively high raw material requirements, and achieve good hydrothermal stability, The preparation process is simple and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

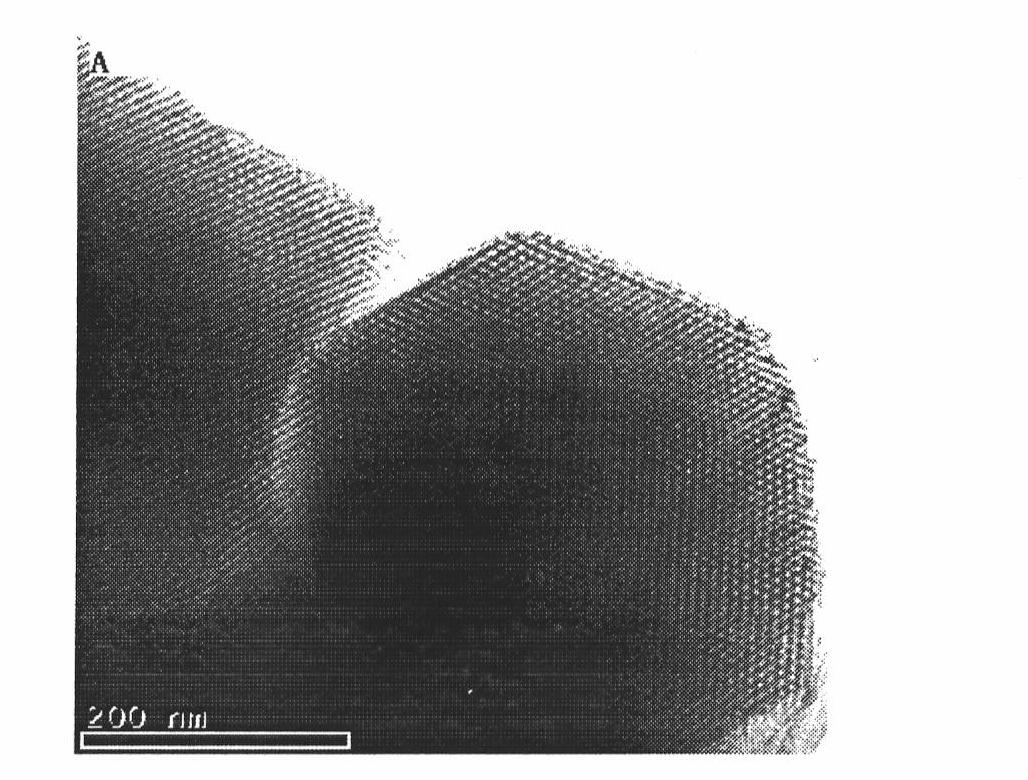

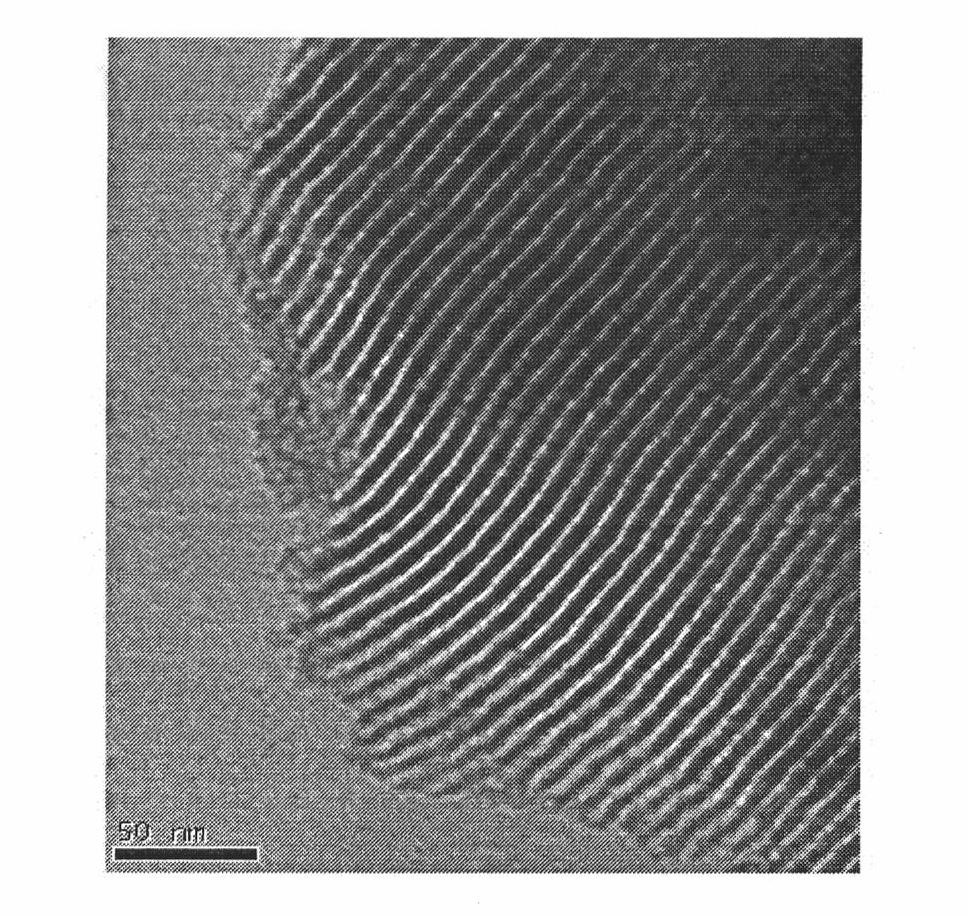

[0032] 2.0 grams of triblock copolymer surfactant polyoxyethylene-polyoxypropylene-polyoxyethylene EO 20 -PO 70 -EO 20 (P123) was dissolved in 60.2g of 2M hydrochloric acid and 15mL of deionized water, and stirred evenly until a transparent solution was formed. The solution was placed in a water bath at 40°C, and then 4.25 grams of tetraethyl orthosilicate was slowly added dropwise to the surface active solution, stirred at 40°C for 20 hours, and then hydrothermally treated at 80°C for 24 hours. Finally, after filtering, washing with deionized water, and drying at room temperature, the mesoporous material SBA-15 was prepared for future use.

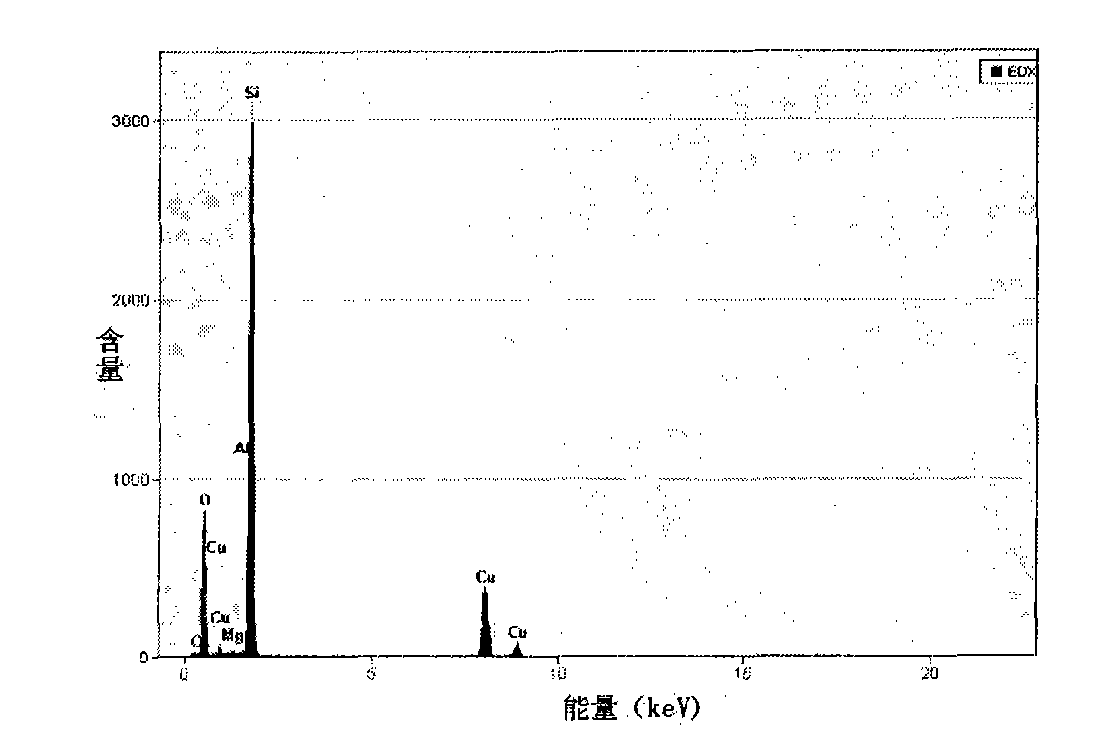

[0033] Take 0.36g precursor Mg(NO 3 ) 2 ·6H 2 O and 0.52g precursor Al(NO 3 ) 3 9H 2 O was mixed with 1.0 g of the above-prepared SBA-15 mesoporous material matrix (i.e. the molar ratio of Si:Mg and Si:Al was 12), mechanically ground for 30 min, and then heated at a rate of 1 °C / min in a roasting furnace. The room temperature was...

Embodiment 2

[0035] The preparation method is the same as in Example 1, only changing the amount of the precursor, that is, getting 0.71g of the precursor Mg(NO 3 ) 2 ·6H 2 O and 1.04g precursor Al(NO 3 ) 3 9H 2 O was mixed with 1.0 g of the SBA-15 mesoporous material precursor prepared in Example 1 (Si: Mg and Si: Al molar ratio was 6), mechanically ground for 30 min, and then heated at a rate of 1 °C / min in a roasting furnace , from room temperature to 500°C, and calcined for 6 hours to obtain an acid-base functionalized mesoporous material.

Embodiment 3

[0037] The preparation method is the same as in Example 1, only changing the amount of the precursor, i.e. getting 1.07g of the precursor Mg(NO 3 ) 2 ·6H 2 O and 1.56g precursor Al(NO 3 ) 3 9H 2 O was mixed with 1.0 g of the SBA-15 mesoporous material precursor prepared in Example 1 (Si: Mg and Si: Al molar ratio was 4), mechanically ground for 30 min, and then heated at a rate of 1 °C / min in a roasting furnace , from room temperature to 500°C, and calcined for 6 hours to obtain an acid-base functionalized mesoporous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com