Processing visual device for light-emitting diode (LED) laser cutting-up machine

A technology of light emitting diodes and visual devices, applied in the field of visual devices, can solve the problems of inability to meet the requirements of rough wafer dicing and high price, and achieve the effects of compact structure, low cost and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

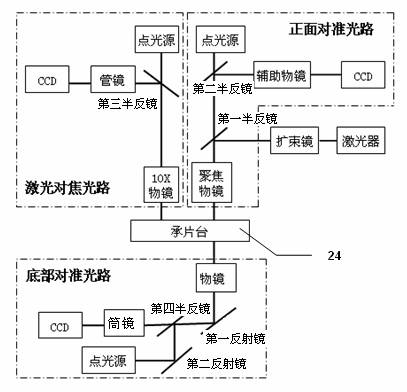

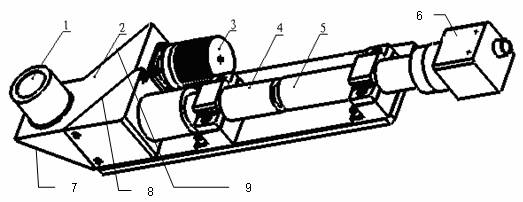

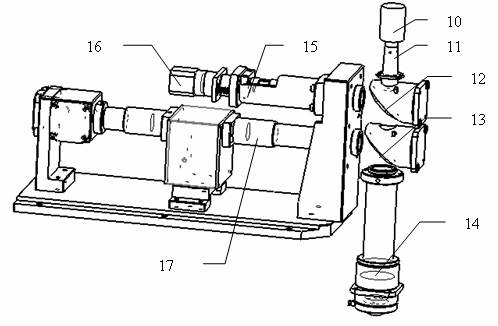

[0021] Embodiment 1: see figure 1 ~Figure 7, the LED (light-emitting diode) laser scribing machine processing visual device has a front alignment optical path coaxial with the laser processing optical path, which is used for the backside identification and positioning of transparent wafers and real-time monitoring of processing, and the front alignment optical path The focusing objective lens (14), the first half mirror (13), the second half mirror (12), the auxiliary objective lens (15) and the CCD camera (16) are installed sequentially from bottom to top, and the laser beam passes through the first half mirror The mirror (13) is coaxially coupled into the front alignment optical path; a bottom alignment optical path coaxial with the laser processing optical path is used for front identification and positioning of special roughened wafers, and the bottom alignment optical path is sequentially installed with objective lenses from top to bottom (1), the first mirror (7), the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com