Thermostatic expansion valve

A technology of thermal expansion valve and valve body, applied in the field of thermal expansion valve, can solve the problems of short working life, affecting the service life of the valve, leakage of the refrigeration system, etc. The effect of adjusting the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

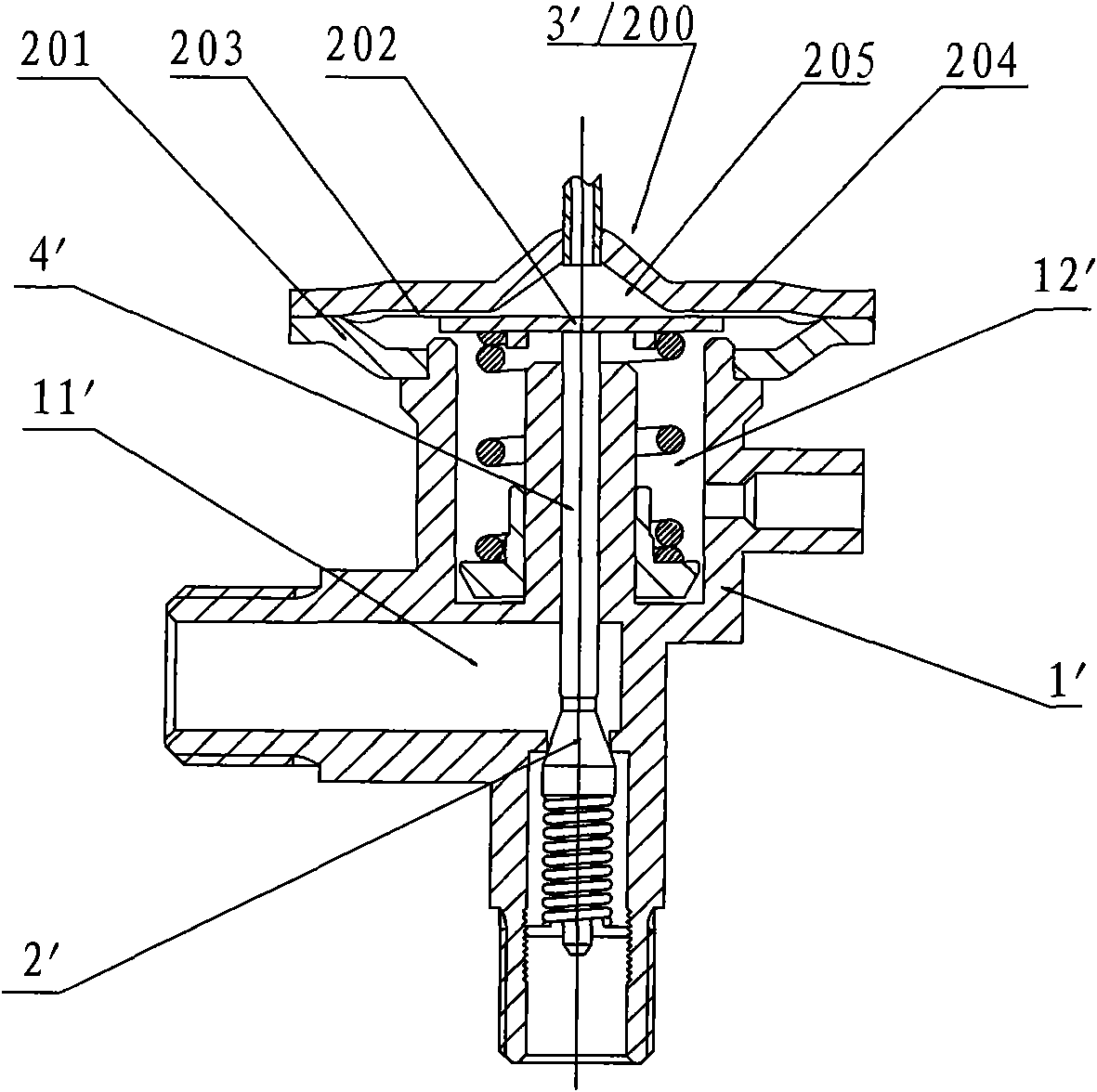

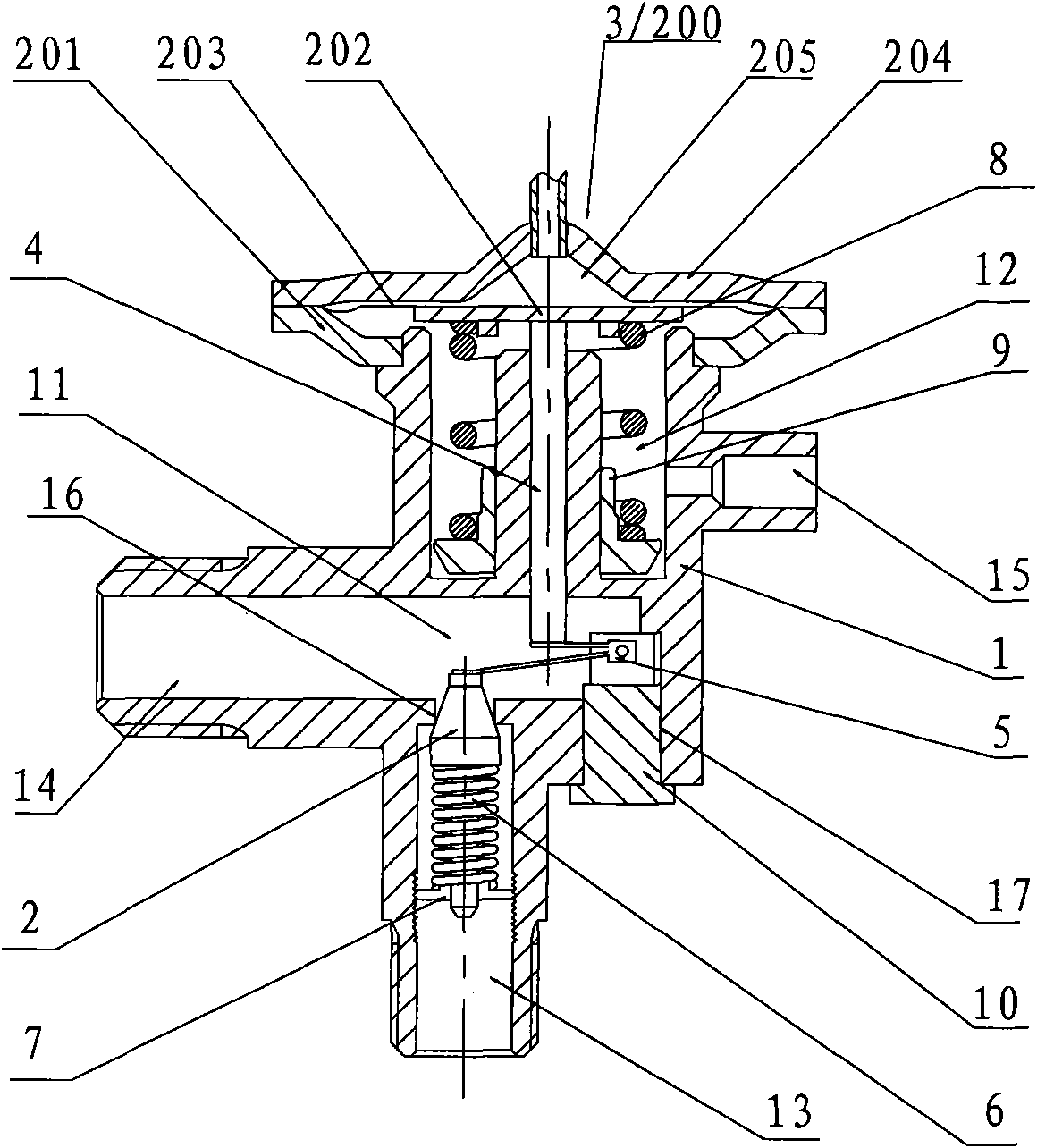

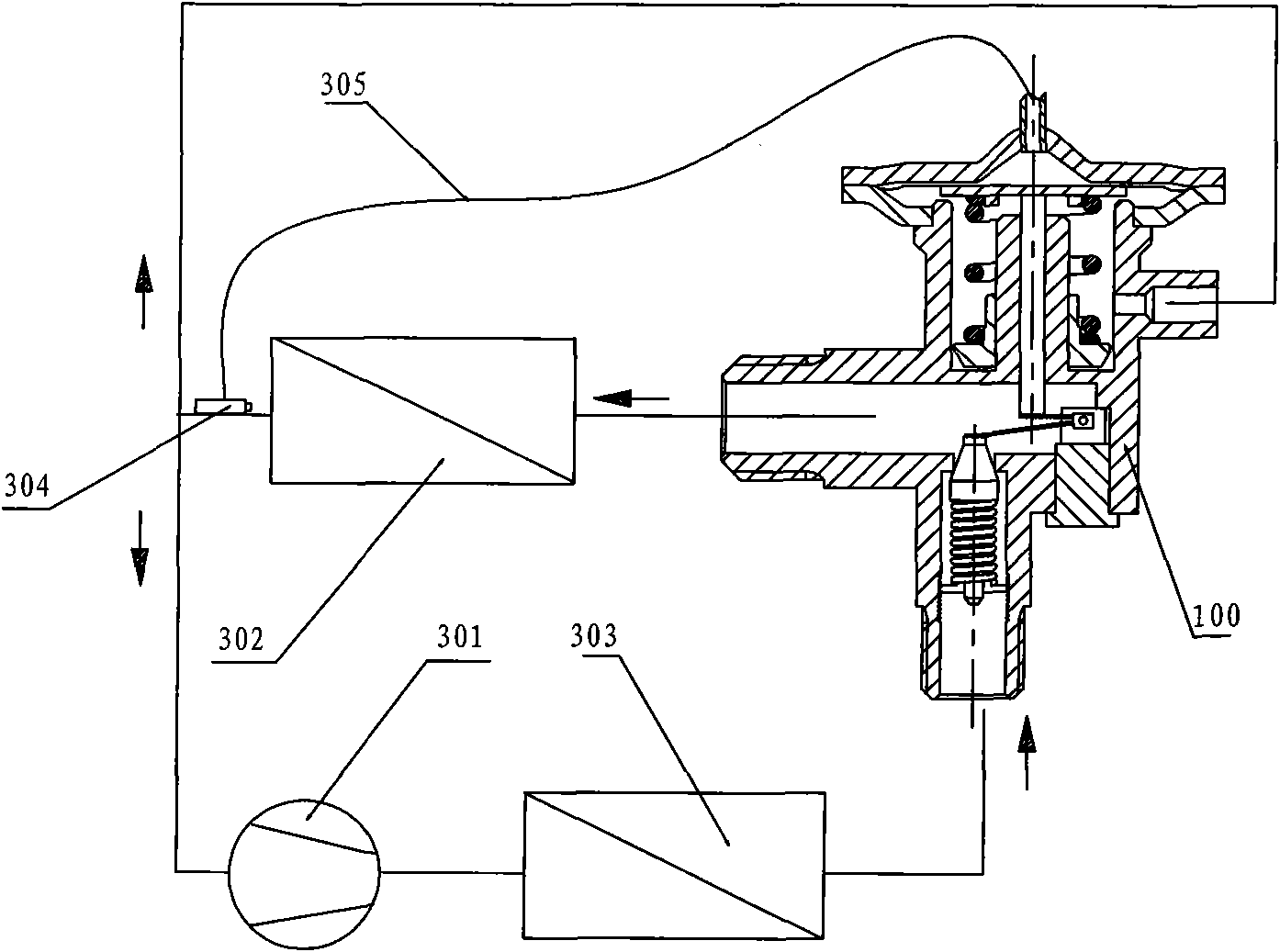

[0047] figure 2 It is a schematic diagram of one of the embodiments of the thermal expansion valve provided by the idea of the present invention; Figure 2A for figure 2 Schematic diagram of the thermostatic expansion valve applied in the refrigeration system.

[0048] Such as figure 2 and Figure 2A As shown, the expansion valve 100 mainly includes a valve body 1 with a throttling chamber 11 and a balance chamber 12, and a spring seat 7 is arranged in the throttling chamber 11, and the valve core adjustment spring 6 on the spring seat 7 adjusts the valve The core 2 abuts against the valve port 16 in the throttling chamber 11 . As the air box head 200 of the temperature sensing component 3, it is airtightly installed at one end of the balance chamber 12 of the valve body 1, the balance channel 15 of the valve body 1 communicates with the balance chamber 12, and the inlet of the throttle chamber 11 of the valve body 1 The channel 13 and the outlet channel 14 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com