Hydrogen energy boiler

A hydrogen energy and boiler technology, applied in the field of high-efficiency heat-exchanging hydrogen energy boilers, can solve the problems of low hydrogen production efficiency and water vapor not meeting the conditions for thermal cracking hydrogen production, so as to increase the amount of hydrogen released and overcome hydrogen production The effect of low efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

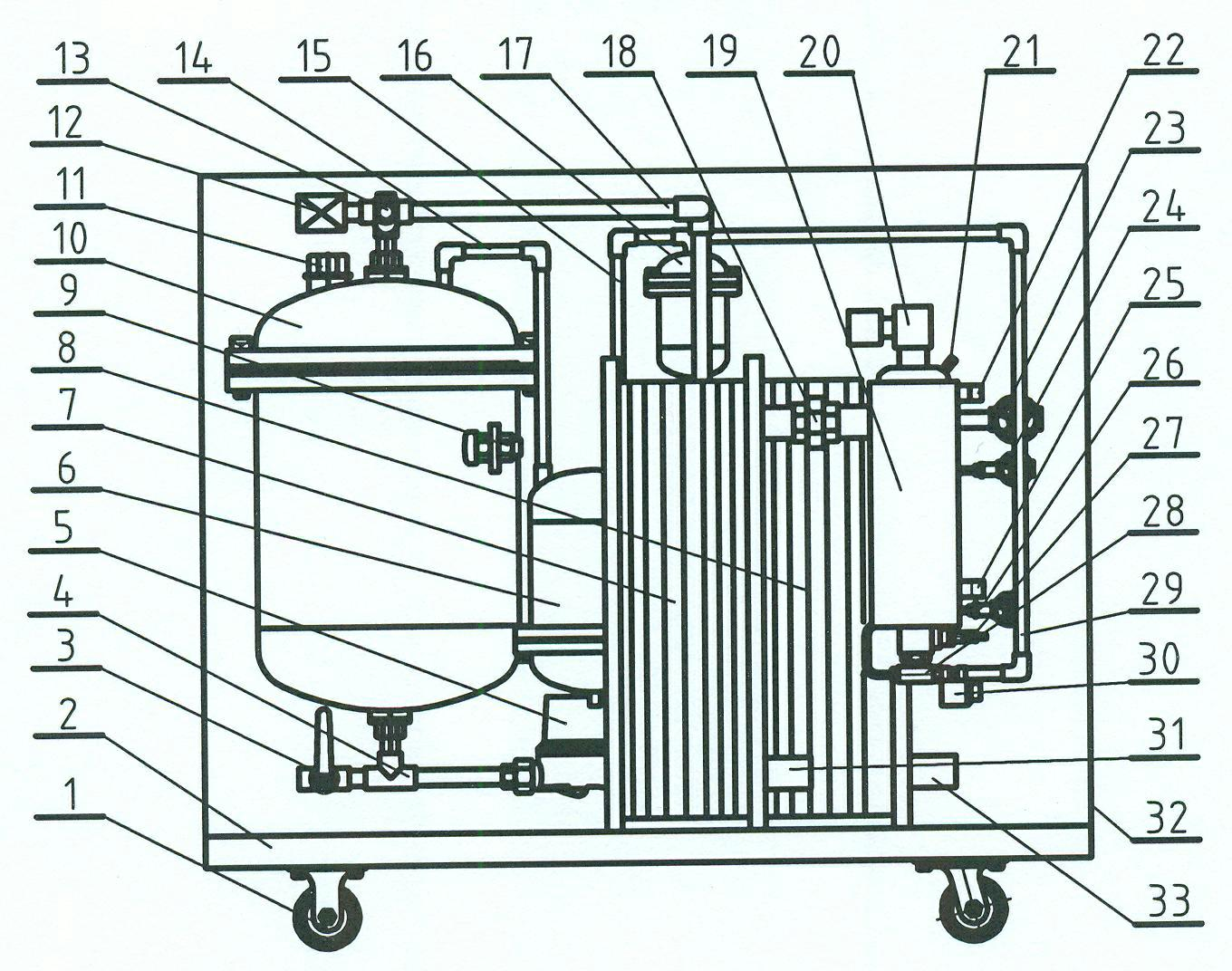

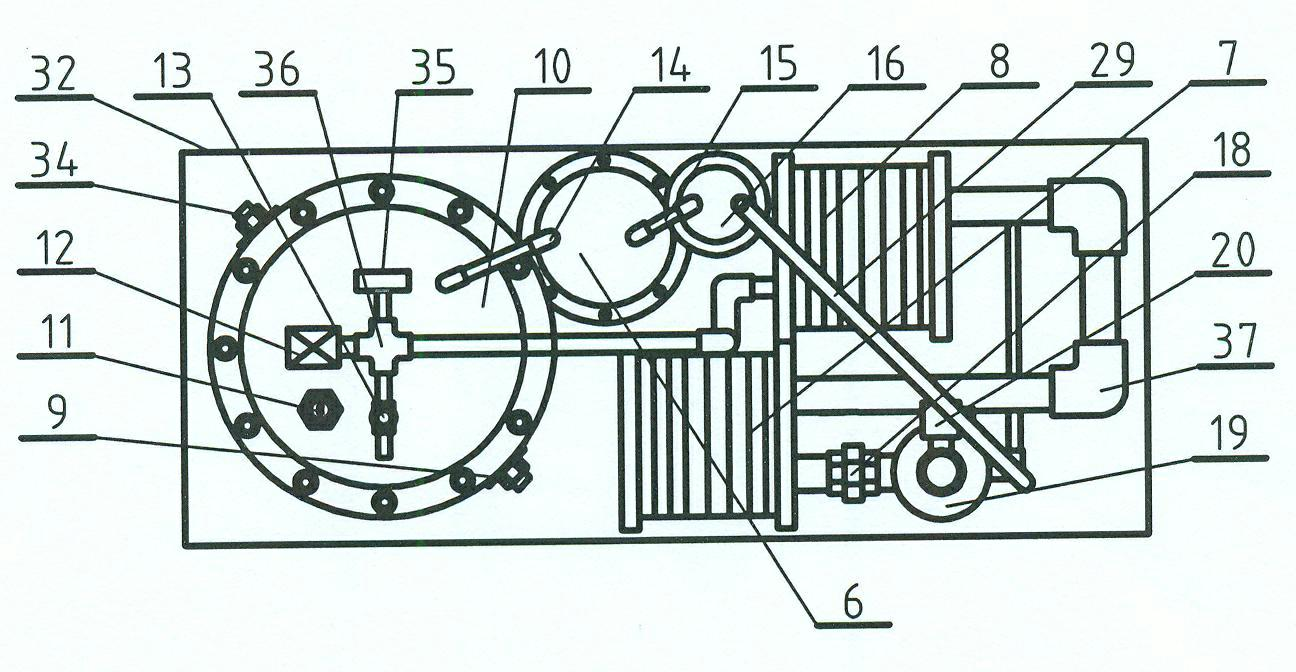

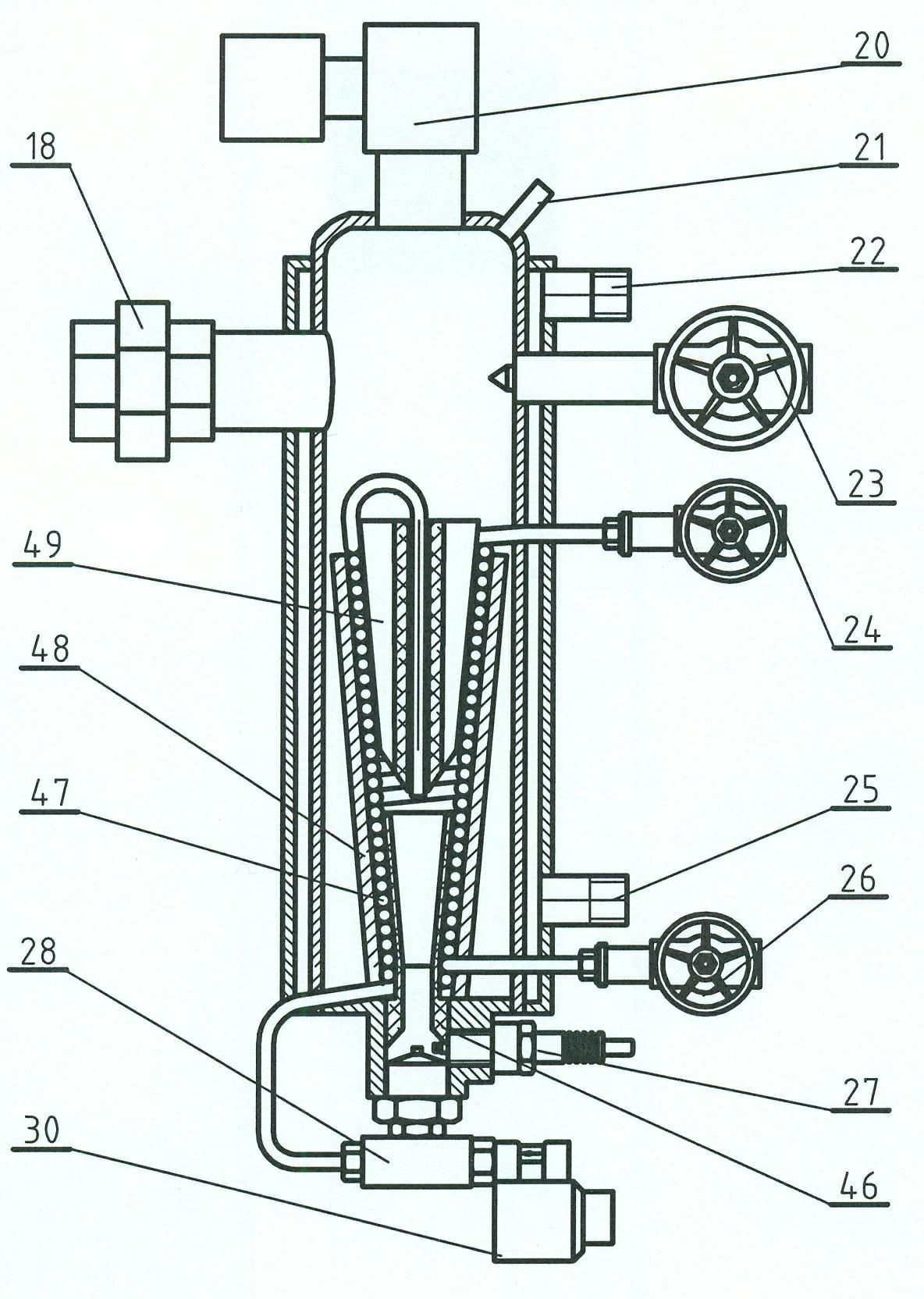

[0025] Combine below Figure 1-9 The specific structure of the present invention will be further described. This hydrogen energy boiler includes a base 2 with a casing 32 and casters 1, a hydrogen and oxygen fuel burner 19 assembled on the base, a float level gauge 11, a water replenishment check valve 13 and a safety valve 12. Hydrogen and oxygen generating tank 10, circulating water pump 5, high and low temperature heat exchangers 7 and 8, and high-frequency DC pulse power supply connected by wires, wherein the burner adopts a heat-induced hydrogen-producing burner, and a heat-induced hydrogen-producing burner has 19 shells A spiral heating tube 47 with a sheath 48 and a heat-resistant ceramic bushing 46 is arranged in the body, a heat-resistant ceramic heat island 49 assembled in the coil center of the spiral heating tube 47 and a gas nozzle 28 fixed on the base of the housing; 10. The oxygen generation tank passes through the gas-liquid separation tank 6 and the anti-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com