Analytical method of small-size impurities in steel

An analysis method and technology of inclusions, applied in the direction of analysis of materials, instruments, etc., can solve the problems that are not suitable for detection and analysis of inclusions in clean steel products, incomplete retention of large inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

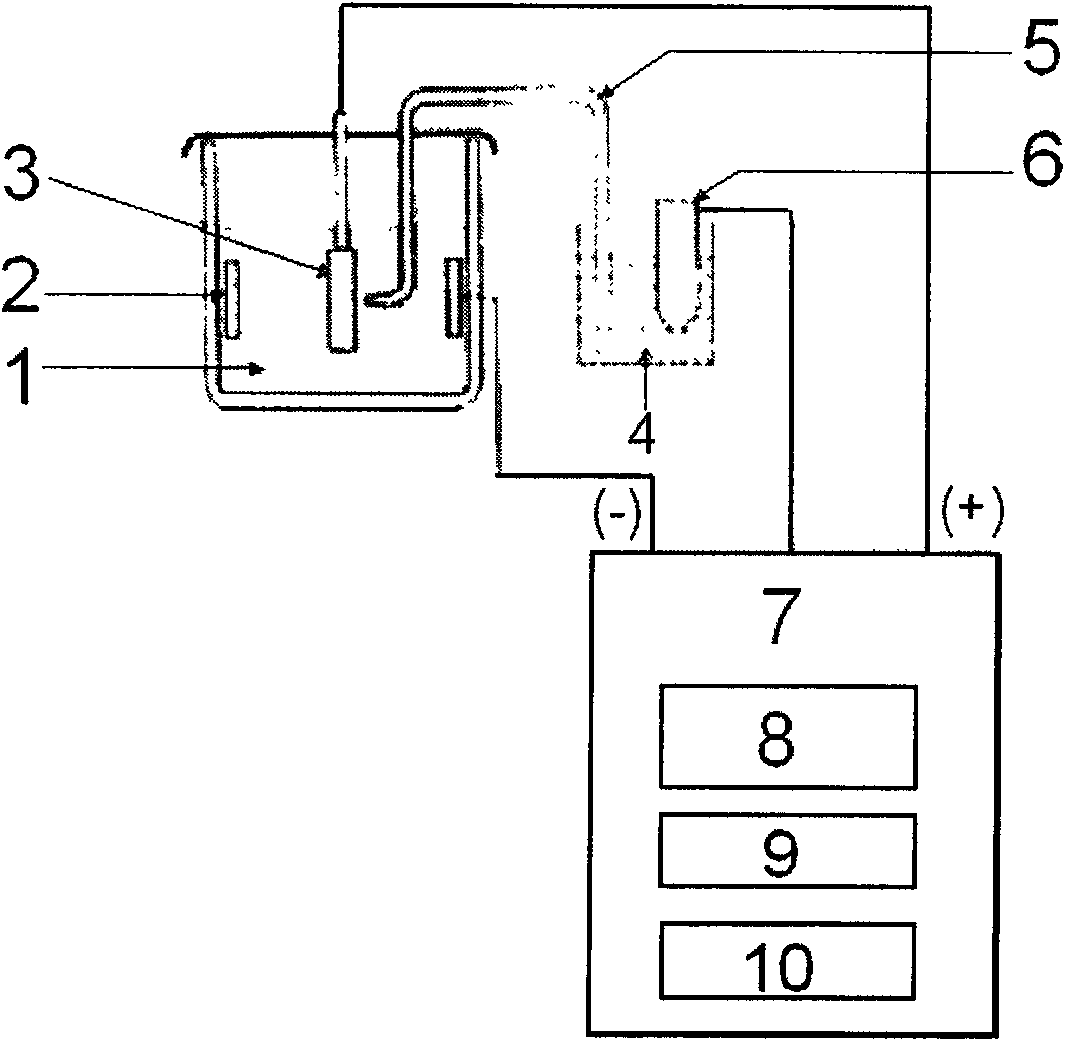

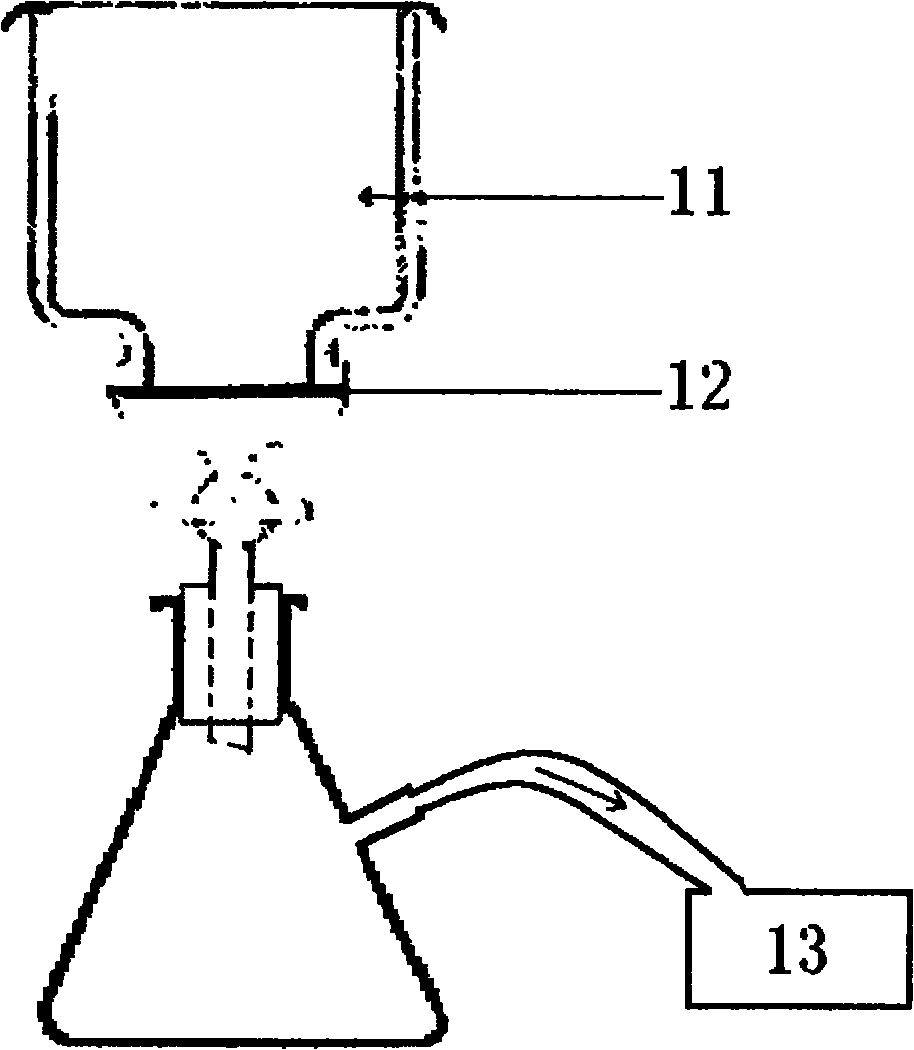

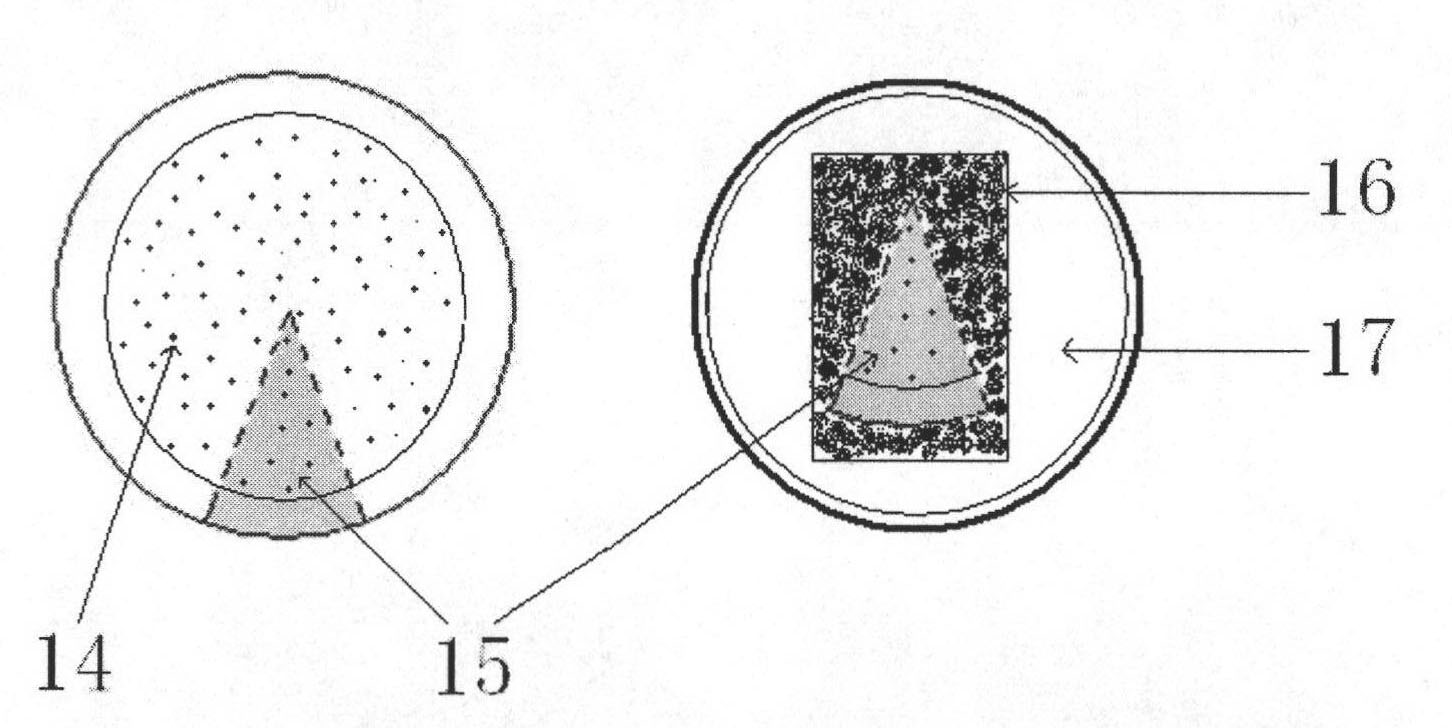

[0028] The specific implementation of the present invention will be described below with reference to the accompanying drawings, taking the statistical analysis of inclusions in a certain low-carbon steel as an example.

[0029] The analysis and research of small inclusions in steel includes several steps such as pre-experiment preparation, electrolytic extraction experiment, scanning electron microscope particle analysis, and data statistical analysis, as follows:

[0030] ① Preparation before experiment

[0031] First prepare the electrolytic bridge, configure the electrolyte 1, and the proportioning scheme is shown in Table 1:

[0032] Table 1 Proportion scheme of electrolyte

[0033] Matching plan

Acetylacetone / ml

Tetramethylamine chloride / g

Total methanol solution / ml

A

8

0.9

100

B

10

1

100

C

13

1.2

100

[0034] In the analysis of this example, the electrolyte solution 1 is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com