Micro solenoid radio frequency coil for microfluid nuclear magnetic resonance detection and manufacturing method thereof

A nuclear magnetic resonance and radio frequency coil technology, which is applied in the direction of using nuclear magnetic resonance for analysis, magnetic resonance measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

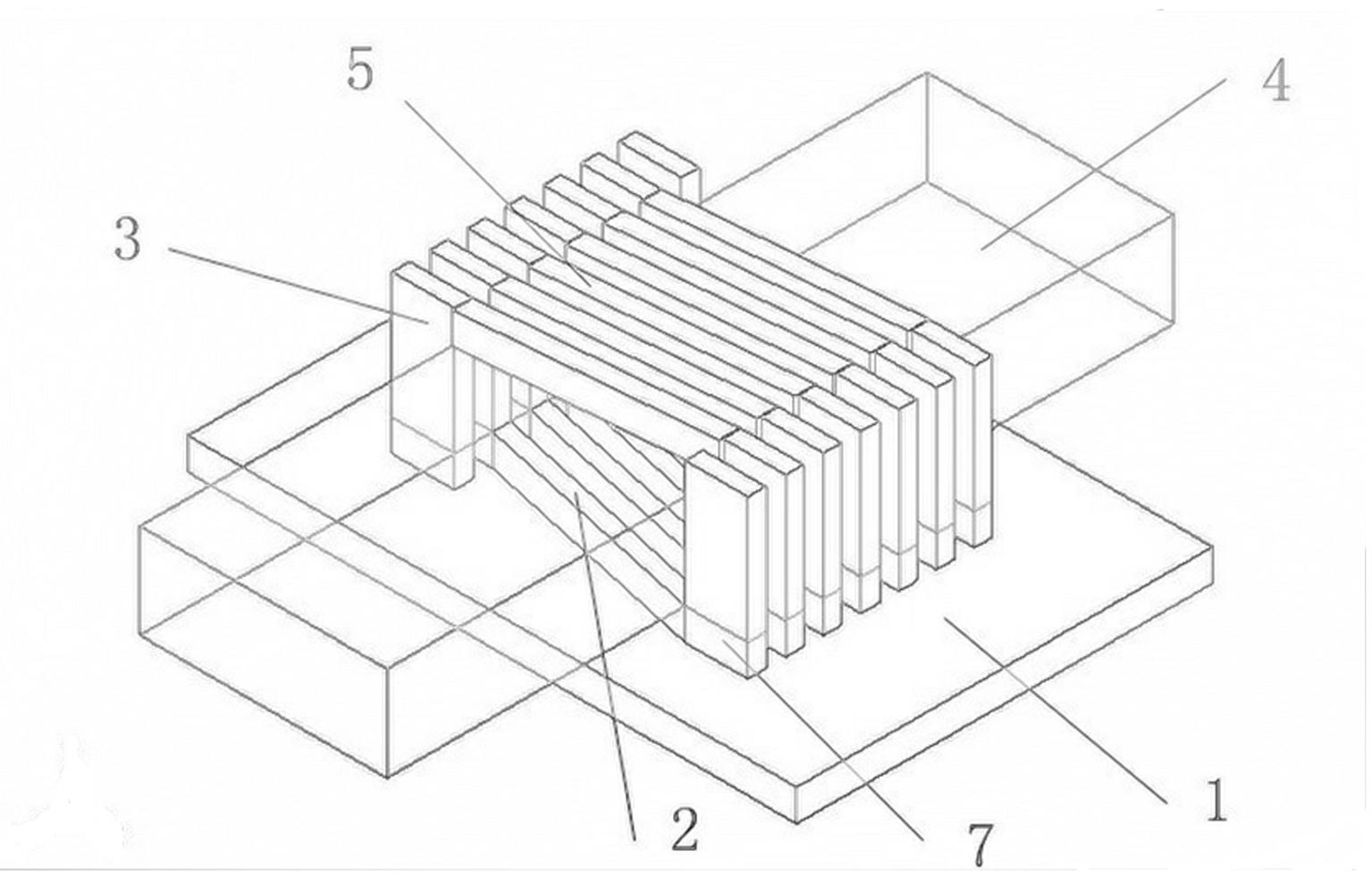

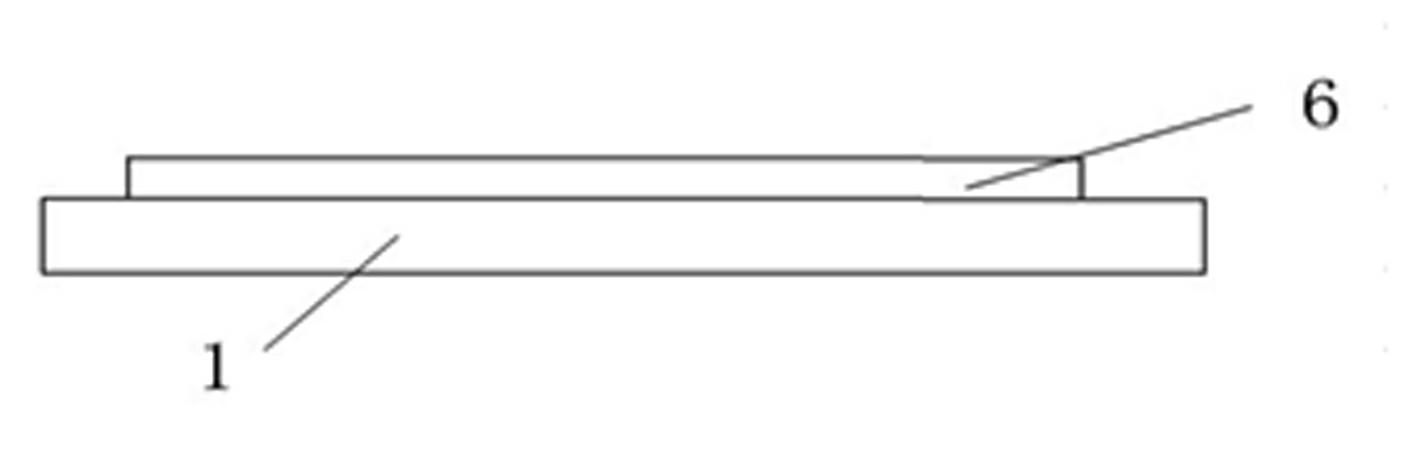

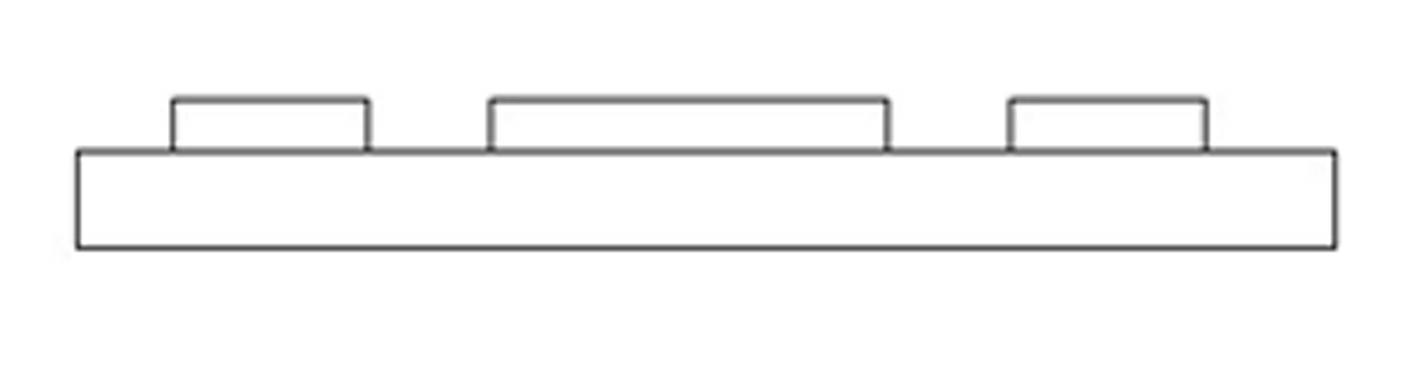

[0037] see figure 1 , the insulating substrate (1) of this embodiment is a rectangular thin plate made of heat-resistant glass, the microfluidic channel (4) for placing the sample to be tested is a square capillary glass tube, and the left and right rows of bottom coils (7) each There are 7 rows, and correspondingly there are 7 cylindrical coils (3) arranged on the top of the bottom coils (7) in each row, connecting the bottom oblique strip coils (2) of the two rows of bottom coils (7) and connecting the two rows There are 6 oblique strip coils (5) on the top layer of the cylindrical coils (3), and the inclination directions of the oblique strip coils (2) on the bottom layer and the oblique strip coils (5) on the top layer are opposite. The above-mentioned coils are made of copper, and are connected to each other to form a solenoid coil with six turns.

[0038] see Figure 2a --2i, the manufacturing method of the present embodiment is as follows:

[0039] 1. Deposit SU-8 ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com