Connection method for thin-wall stainless steel pipes, its special tubular joint and its production method

A technology of stainless steel pipes and connection methods, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc., which can solve the problems of poorly adjusted connection installation, weak connection, and easy influence on water quality, etc., to achieve It is not easy to loosen or leak, save materials, and have the effect of flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

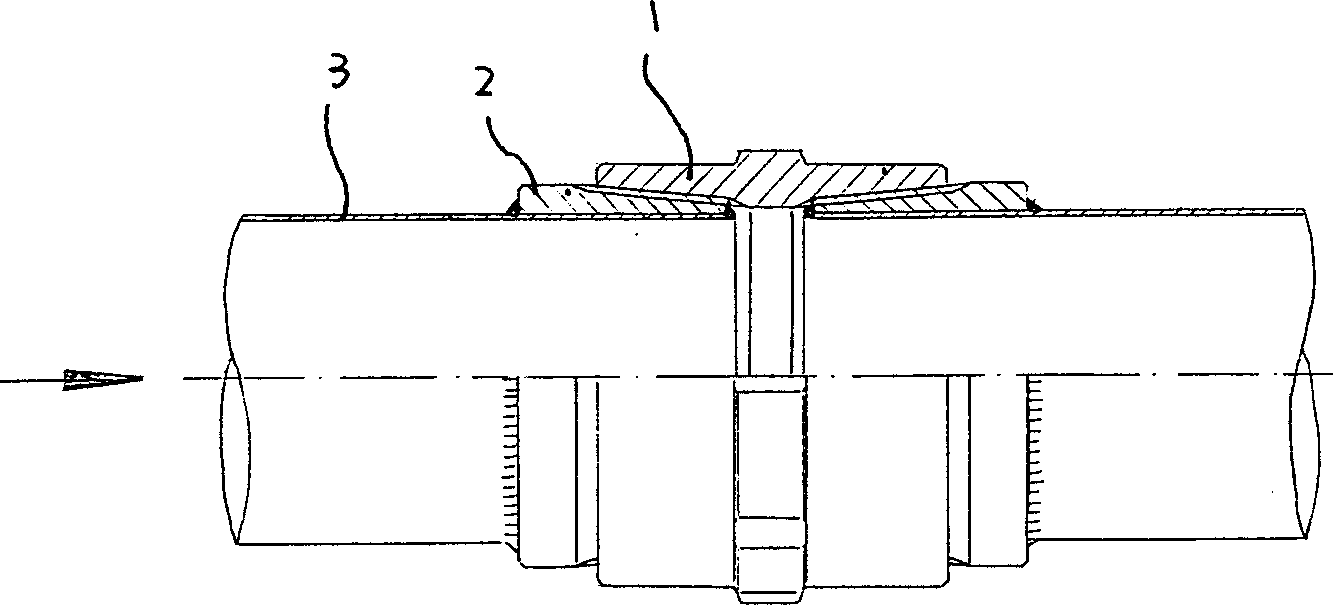

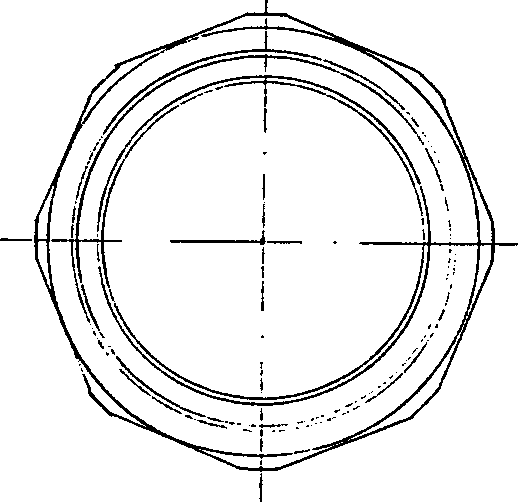

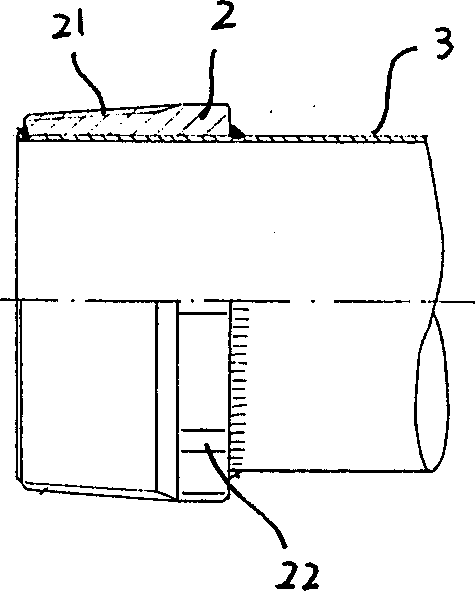

[0021] Example 1, such as Figure 1-3 As shown, the pipe joint is a straight-through structure, with a screw sleeve 2 with an external thread, and a tapered thread 21 is manufactured from the end of the screw sleeve to the middle surface, generally with a specification of 55°, at a position 6-12 mm away from the outer mouth. A position structure 22 for wrench engagement is made on the top, which can be a spline structure or a polygonal structure, such as hexagonal, octagonal, etc. The inner diameter of the screw sleeve matches the thin-walled stainless steel pipe 3, and the front end and / or tail end are also welded. Then insert the thin-walled stainless steel pipe into the screw sleeve, and connect them with argon arc welding at the front and / or rear ends, and another pipe joint 1, made of seamless steel pipe, with a position for the wrench to bite in the middle Structures, such as splines or polygons, are made with internal threads inside the mouth, which are also 55°, and th...

Embodiment 2

[0022] Example 2, such as Figure 4-5 As shown, the pipe joint is a straight-through structure, with a screw sleeve 2 with an external thread, and a tapered thread 21 is manufactured from the end of the screw sleeve to the middle surface, generally with a specification of 55°, at a position 6-12 mm away from the outer mouth. A position structure 22 for wrench engagement is made on the top, which can be a spline structure or a polygonal structure, such as hexagonal, octagonal, etc. The inner diameter of the screw sleeve matches the thin-walled stainless steel pipe 3, and then the thin-walled stainless steel pipe is inserted into the screw. In the sleeve, there is a welding cavity 23 between their contact surfaces, and they are connected by brazing, and a pipe joint 1 is made of seamless steel pipe, and there is a position structure for a wrench to engage in the middle, such as a spline or Polygonal, with internal threads inside the mouth, also 55°, and then connected by threads...

Embodiment 3

[0023] Example 3, such as Figure 6-7 As shown, the pipe joint is a three-way structure. The screw sleeve of the external thread is processed by No. 304 or No. 316 seamless steel pipe. The inner surface of the end to the middle of the screw sleeve is made with a tapered thread, generally 55°. A position structure for wrench engagement is made at the tail position, which can be a spline structure or a polygonal structure, such as hexagonal, octagonal, etc. The inner diameter of the threaded sleeve matches the thin-walled stainless steel pipe, and there is also a front end and / or tail end. Then insert the thin-walled stainless steel pipe into the screw sleeve, and connect them with argon arc welding at their front and / or rear ends. The pipe joint 1 is divided into welded connection with the pipe joint body 11 and the screw sleeve 12, and the inside of the screw sleeve Internal threads 13 are formed on the surface, which can be processed by No. 304 or No. 316 seamless steel pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com