Core column component of winding type pasted electronic element and manufacturing method thereof

A technology of electronic components and manufacturing methods, applied in the direction of electrical components, inductor/transformer/magnet manufacturing, transformer/inductor magnetic core, etc., can solve the problems of limited applicable wire diameter, increase the overall height of the product, etc., to facilitate surface mount , Improve product reliability, good coplanarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

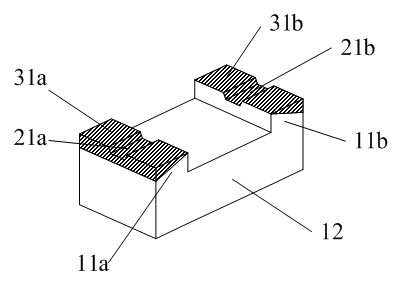

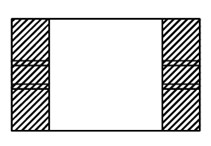

[0030] like Figure 1 to Figure 2c As shown, a stem part of a wire-wound mounted electronic component includes a stem and external electrodes 31a, 31b. The stem main body 12 of the right end protrusion 11b; the left end protrusion 11a is provided with a groove 21a, and the right end protrusion 11b is provided with a groove 21b; the external electrode 31a continuously covers the upper surface of the left end protrusion 11a and the groove 21a On the surface of the outer electrode 31b, the outer electrode 31b is continuously covered on the upper surface of the right end protrusion 11b and the surface of the groove 21b. In order to make the stem component more stable after mounting and increase the contact area between the outer electrode and the installation motherboard, this specific implementation Part of the side surfaces of the left end protrusion 11a and the right end protrusion 11b of the stem member of the above method are also covered with the external electrode layer.

...

specific Embodiment approach 2

[0033] like Figure 3 to Figure 4c As shown, the stem part of the wire-wound mount electronic component in this specific embodiment is a magnetic core part, including a stem and an external electrode, and its overall structure is the same as that of the wire-wound mount electronic component in Embodiment 1. The components of the core column are the same, the difference is that the core column in this specific embodiment adopts a magnetic core made of ferrite.

[0034] like Figures 5 to 6 As shown, the manufacturing process flow of the stem component of the wire-wound mounted electronic component in this specific embodiment is as follows:

[0035] Step S1: a mold preparation process, that is, a process of prefabricating the mold required for forming the magnetic core. As an example, high-hardness, wear-resistant tungsten steel can be processed into the shape of the magnetic core shell by a lathe to form the mold protrusion required for making the magnetic core groove, and th...

specific Embodiment approach 3

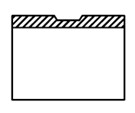

[0045] like Figure 7 As shown, the difference between this specific embodiment and the stem part of the wire-wound SMT electronic component in Embodiment 1 is that the grooves 21a and 21b of this specific embodiment are respectively located in the middle of the left end protrusions 11a and 11b, and Intersects the electrode plane at an acute angle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com