Method for cutting LED chip

A technology of LED chips and cutting methods, which is applied to fine working devices, electrical components, circuits, etc., can solve the problems of destroying the light-emitting area, reducing the area of the light-emitting area, affecting product quality, etc., and achieves the goal of simple process and increased chip production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

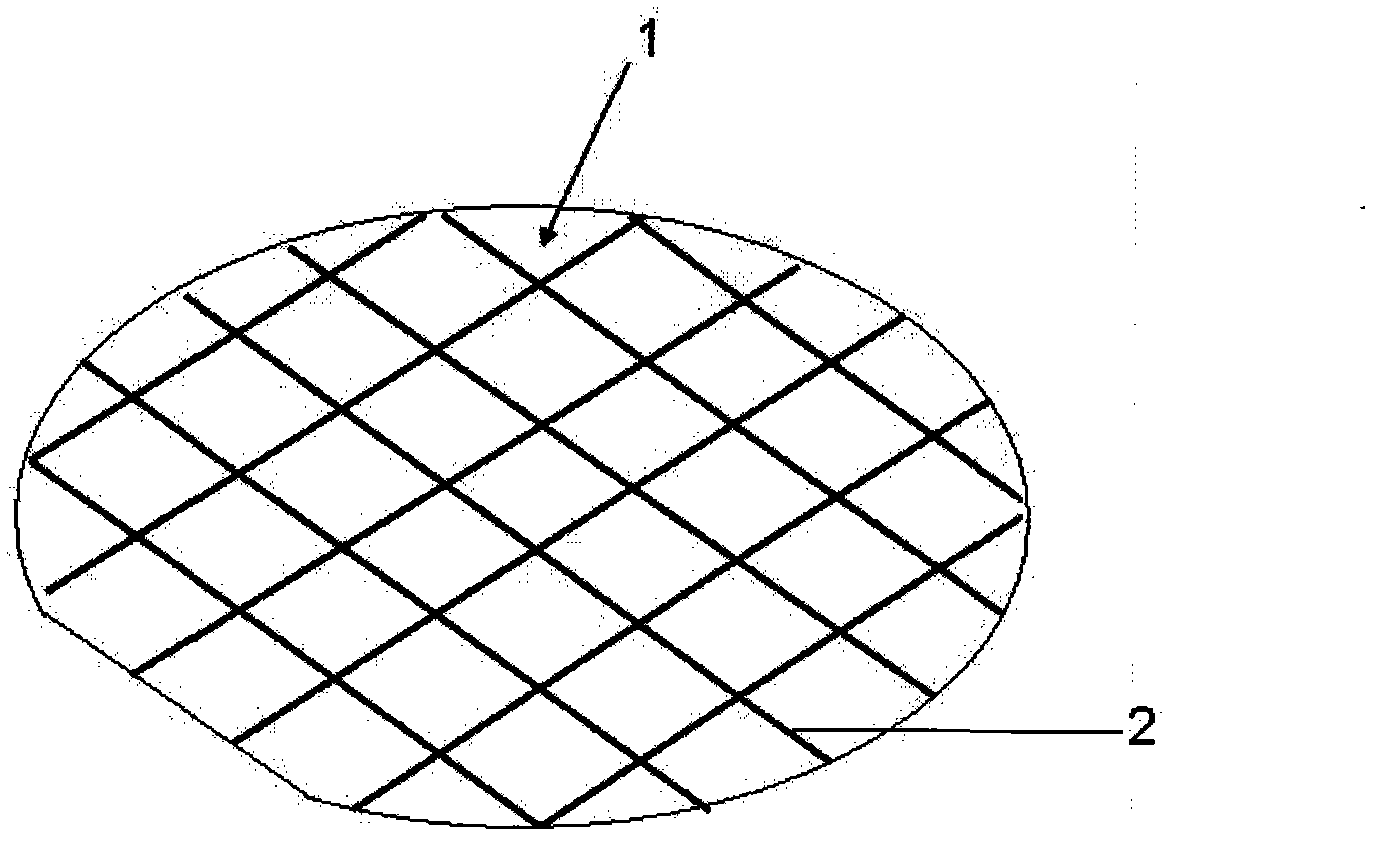

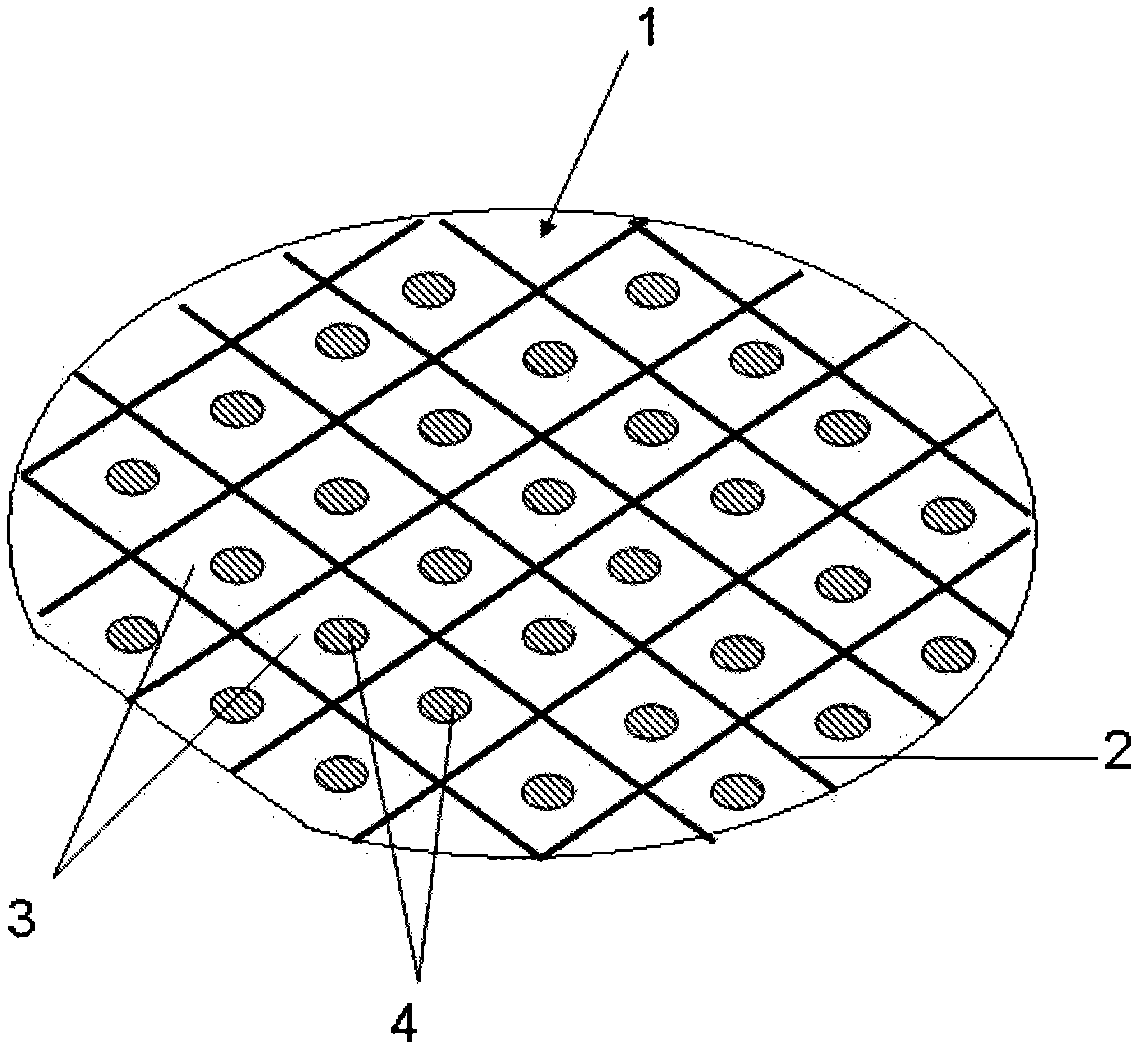

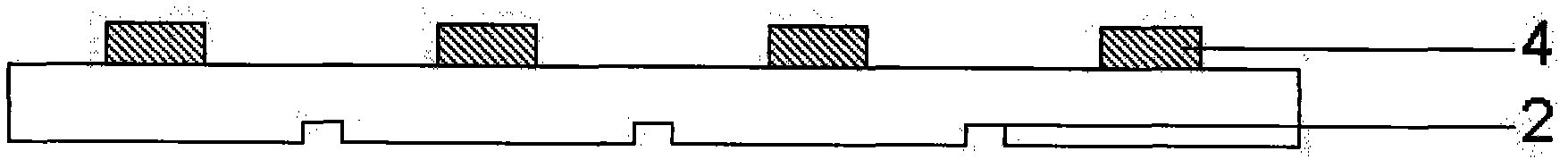

[0017] The LED chip cutting method of the present invention will be described in detail below with reference to the accompanying drawings, taking gallium arsenide LED chip cutting as an example.

[0018] 1 SMT: Paste the front side (P side) of the gallium arsenide chip 1 on a piece of blue film so that the back side (N side) faces up, and then put the chip together with the blue film on the saw blade carrier On the platform, it is fixed by suction pump;

[0019] 2. Saw blade: After setting the cutting range, cutting depth, cutting speed and chip size and other parameters, start sawing the blade. The saw blade is performed on the back (N side) of the gallium arsenide chip 1, and the cutting depth is set at 1% of the chip thickness. / 6--2 / 3. In this embodiment, the gallium arsenide chip 1 has a thickness of 100 μm, a single chip size of 203 μm, a cutting depth of 40 μm, a cutting period of 203 μm, and a cutting position in the middle of the electrodes. Gallium arsenide chip 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com