Vehicle rotating motor

A technology for rotating electrical machines and vehicles. It is used in the manufacture of motor generators, electromechanical devices, and electrical components. It can solve problems such as excessive temperature rise, and achieve the advantages of shortening length, suppressing excessive temperature rise, and suppressing resistance and copper loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

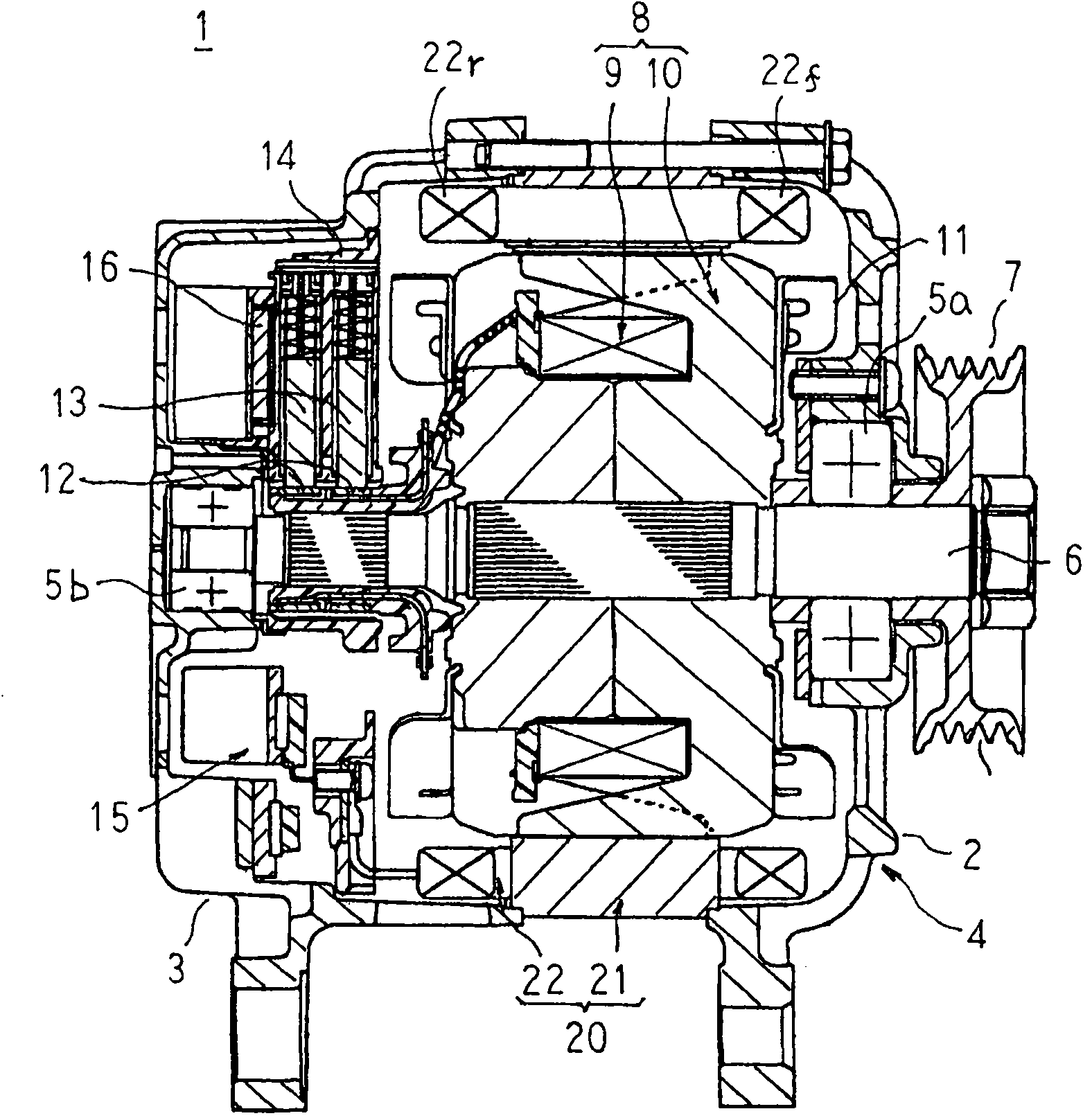

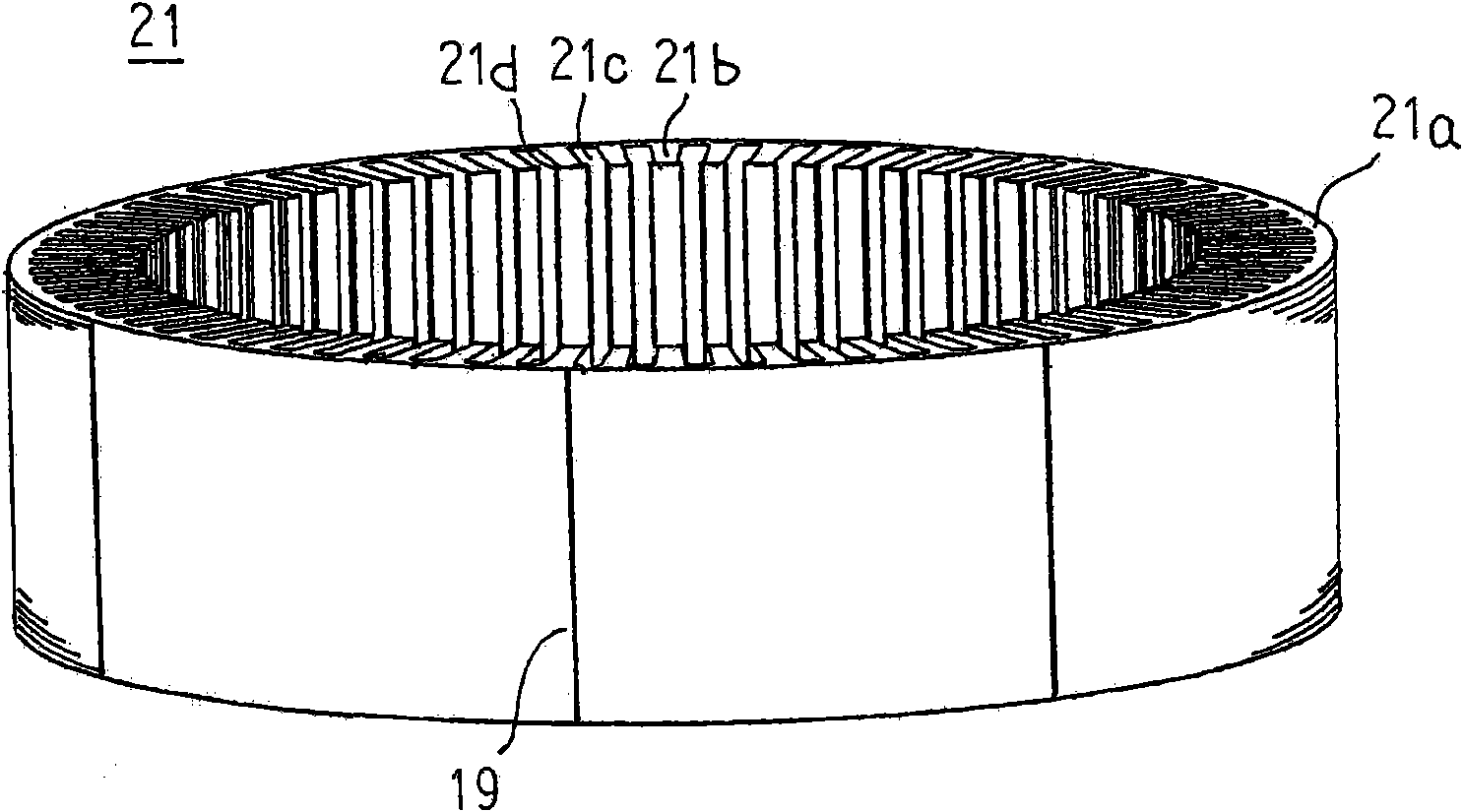

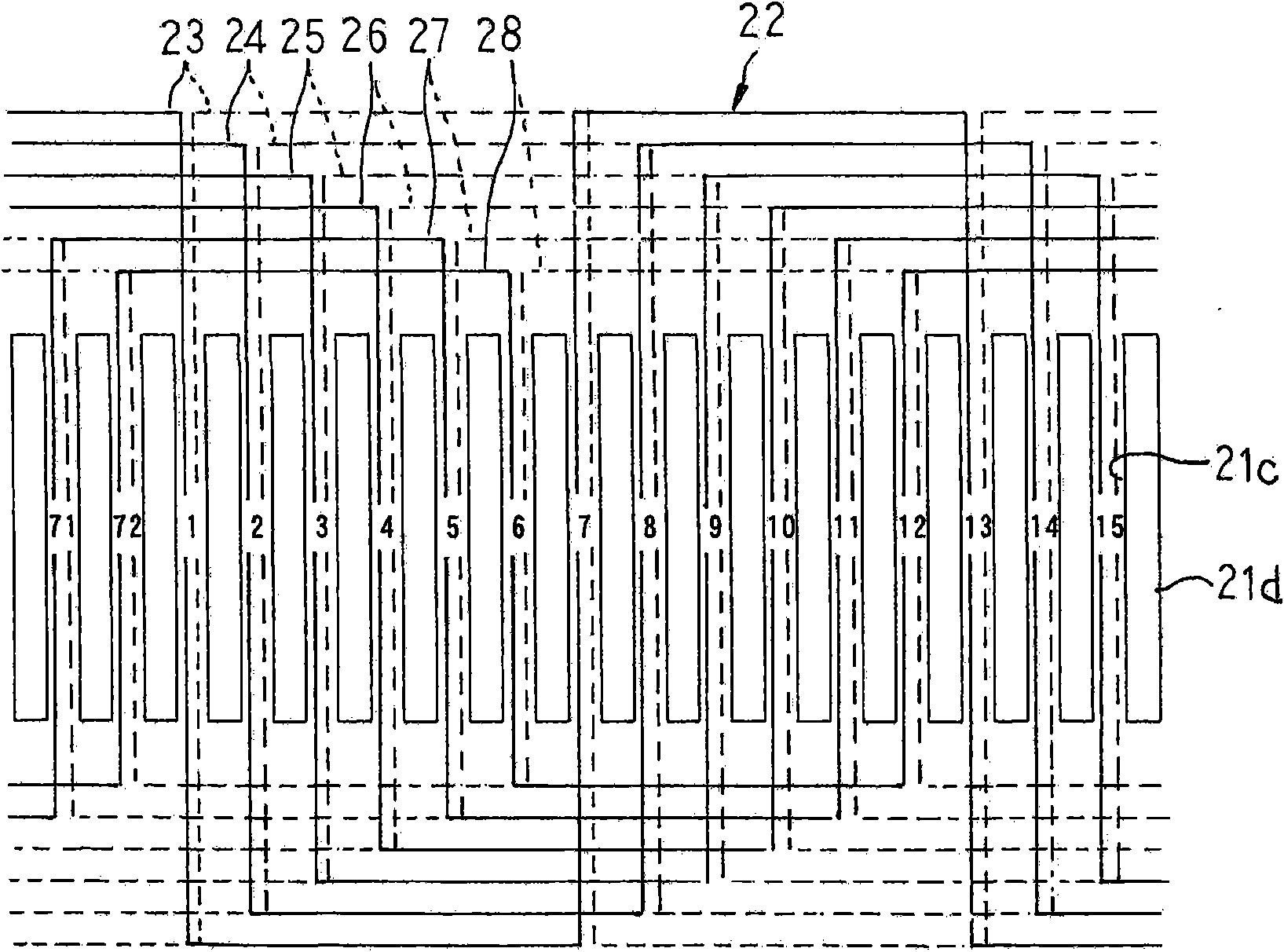

[0063] figure 1 is a longitudinal sectional view showing the automotive alternator according to Embodiment 1 of the present invention, figure 2 It is a perspective view showing a stator core of the automotive alternator according to Embodiment 1 of the present invention. image 3 It is a schematic view explaining the winding state of the stator winding of the automotive alternator according to Embodiment 1 of the present invention, and is a view of the front end of the T-shaped core portion of the stator core viewed from the radially inner side. Figure 4 It is a schematic diagram illustrating the winding state of the stator winding of the automotive alternator according to Embodiment 1 of the present invention, and is a view of one axial end surface of the stator core viewed from the axially outer side. Figure 5 It is a perspective view illustrating the structure of the a-phase winding constituting the stator winding of the automotive alternator according to Embodiment 1 o...

Embodiment approach 2

[0101] Figure 12 It is a sectional view showing a stator of an automotive alternator according to Embodiment 2 of the present invention.

[0102] Figure 12 Among them, the coil end portion 32 of the distribution winding wound on the outer peripheral side of the slot 21c is bent radially inward, and is located on the axially outer side of the coil end portion 32 of the distribution winding wound on the inner peripheral side of the slot 21c. s position.

[0103] In addition, other structures are the same as those of the first embodiment described above.

[0104] Therefore, also in this second embodiment, the same effect as that of the above-mentioned first embodiment can be achieved.

[0105] According to Embodiment 2, since the coil end portion 32 of the distribution winding wound on the outer peripheral side of the slot 21c is bent radially inward, it is located close to the coil end portion of the distribution winding wound on the inner peripheral side of the slot 21c. ...

Embodiment approach 3

[0107] In the third embodiment, the varnish is permeated into the front coil end group 22f and the rear coil end group 22r, and the coil ends 32 are fixed to each other.

[0108] In addition, other configurations are the same as those of Embodiment 1 and Embodiment 2 above.

[0109] According to the third embodiment, since the varnish is permeated into the front coil end group 22f and the rear coil end group 22r, and the coil ends 32 are fixed to each other, the front coil end group 22f and the rear coil end group can be improved. The rigidity of the end group 22r. Therefore, it is possible to prevent the front coil end group 22f and the rear coil end group 22r from coming into contact with the front holder 2 and the rear holder 3 due to vibrations and damaging the insulating coating.

[0110] Here, in the third embodiment, the varnish is impregnated into the front coil end group 22f and the rear coil end group 22r, but the impregnating resin is not limited to the varnish, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com