Reaction device suitable for aldol reaction

A reaction device and reaction technology, applied in the preparation of organic compounds, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as no use value, achieve low cost, convenient separation, simple and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

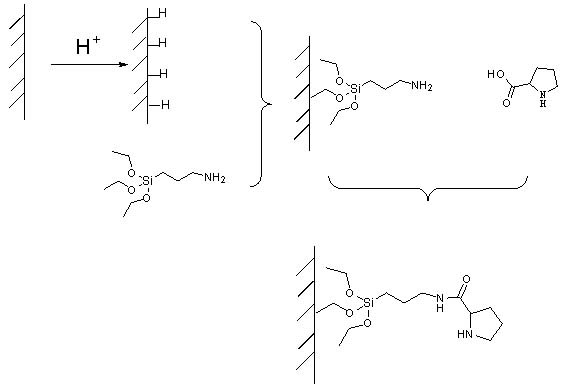

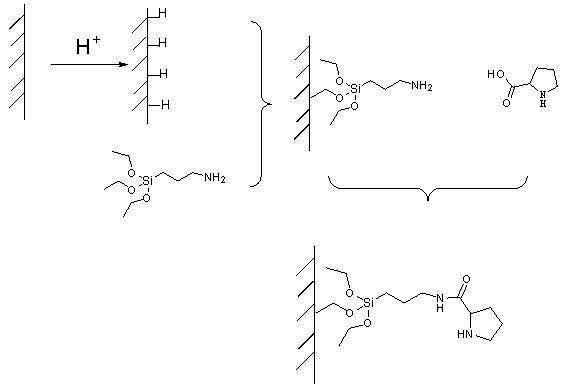

[0028] Embodiment one: see figure 1 , Preparation of proline-loaded silica catalyst

[0029] Disperse 100ml, 300-400 mesh silica gel powder in acidic solution, stir at 60-70°C for 12h, then cool, treat, then disperse in solvent, add 7mL 3-aminopropyl at 40-60°C Triethoxysilane, stirred steadily for 12h, then added 2g of proline into the solution, kept stirring for 4-8h.

Embodiment 2

[0030] Embodiment 2: Construction of catalytic device

[0031] Synthesize the silica gel powder connected with proline according to the claim, put the silica gel powder into the chromatographic column, and then pressurize the silica gel to overfill evenly, then add a sufficient amount of ethanol to remove the proline that is not connected to the silica gel Rinse it down and set aside.

Embodiment 3

[0032] Example 3: Catalyzing different aldehyde and ketone compounds for Aldol reaction experiments

[0033] Operation process: Pour the aldehyde and ketone mixed solution (raw material 1 and raw material 2) mixed in a certain proportion into the chromatography column, rely on gravity to flow down naturally, and after the liquid is completely flowed out, pour the collected solution into the obtained solution in Example 2 Chromatographic column, repeated three times. Then take a sample and carry out GC to measure the composition and the productive rate of the reactant, and the results are shown in Table 1.

[0034] The test instrument is a gas chromatograph with a hydrogen flame detector, and the sample gas is the cylinder standard gas.

[0035] Chromatography conditions: host: GC-2014 gas chromatograph; column: 5A molecular sieve packed column; column temperature: 100°C, detector temperature: 300°C.

[0036] Table 1 Aldol reaction results of different raw materials

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com