Method for treating ABS (acrylonitrile-butadiene-styrenecopolymer) resin production wastewater

A treatment method and technology for producing wastewater, which is applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of failure to meet discharge requirements, unsatisfactory treatment effect, and large amount of flocculant used and other issues, to achieve the effect of low cost, improved biodegradability, and small usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

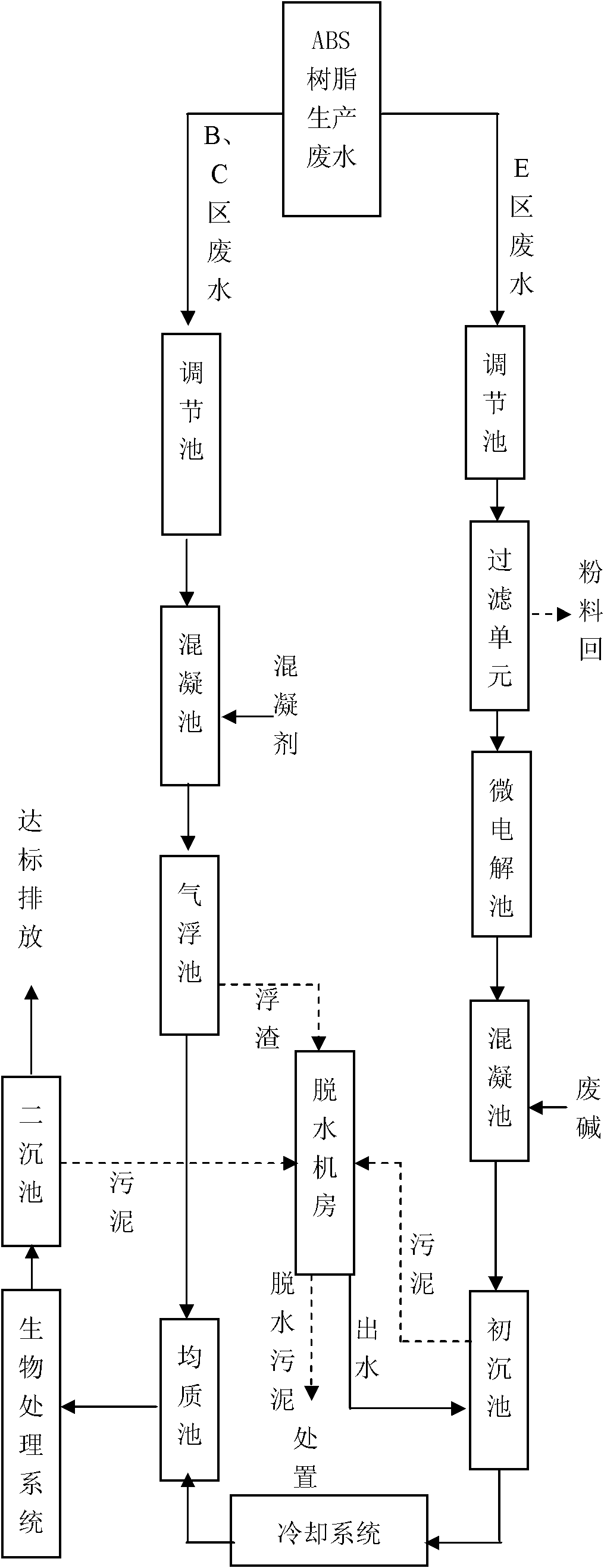

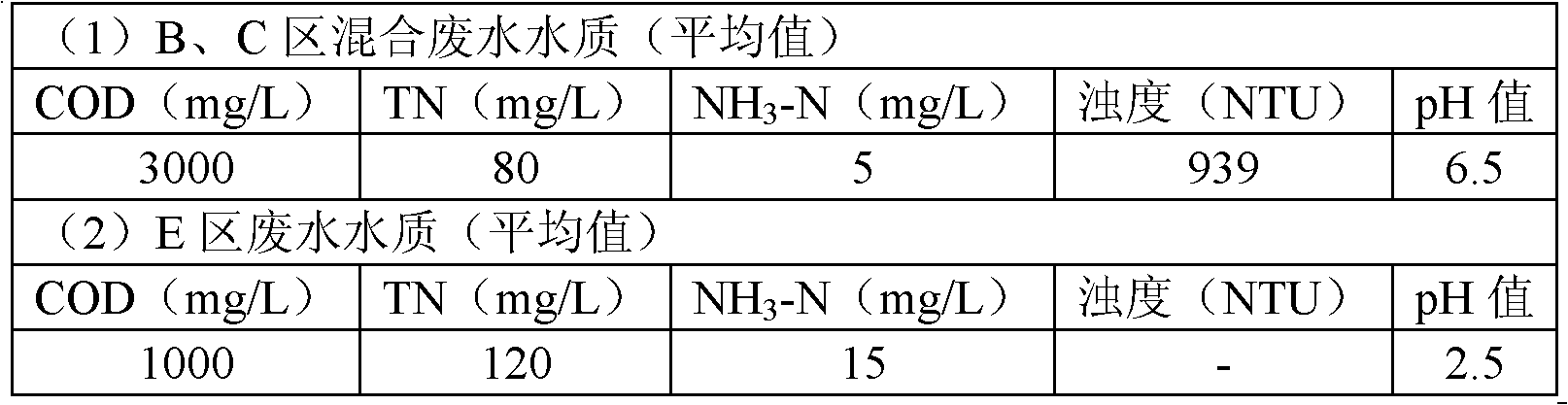

[0014] The flow chart of the ABS resin production wastewater treatment method of the present invention is as follows figure 1 According to the water quality characteristics of wastewater in districts B, C and E, it carries out qualitative treatment.

[0015] The wastewater from Zone B and C is mixed in any proportion and then enters the adjustment tank. The pH value of the adjusted wastewater is 6.0-8.0; the effluent from the adjustment tank enters the coagulation tank, and coagulant is added for coagulation reaction. The coagulant is polyaluminum and polypropylene. For amide, the amount of polyaluminum and polyacrylamide added per ton of wastewater (calculated by dry weight) is 0.25~1.0kg and 1.0~3.0g respectively; the effluent from the coagulation tank enters the air flotation tank and adopts pressurized air flotation. Air flotation scum enters the dehydration machine room, and the effluent from the air flotation pool enters the homogenization pool;

[0016] The wastewater in Zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com