Concrete composite additive and preparation method and use thereof

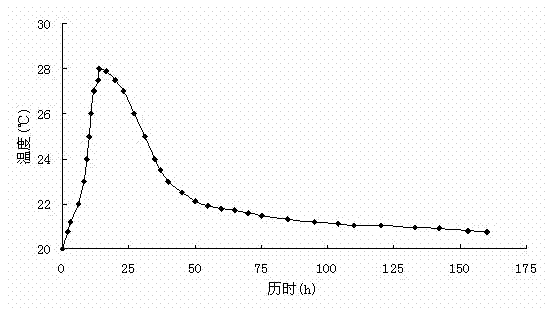

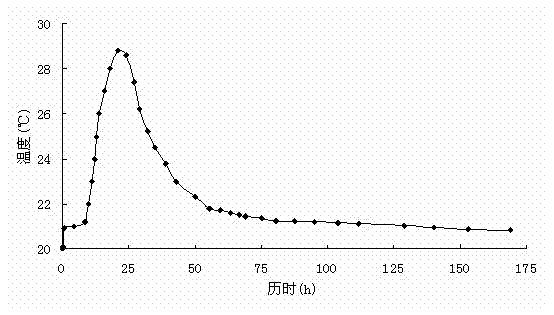

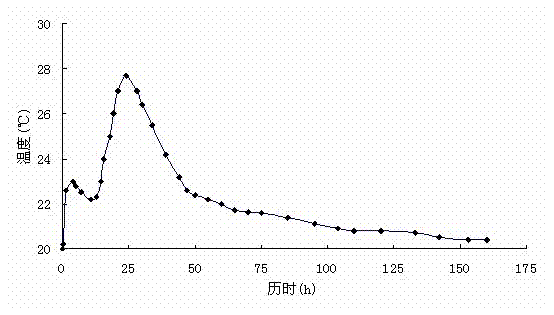

A composite admixture and concrete technology, applied in the field of concrete, can solve the problems of hydration exotherm curve to be improved, and achieve the effects of engineering temperature control and crack prevention, good cooling effect, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 65kg naphthalene sulfonate formaldehyde condensate (NaSO 4 The content is less than 5wt%), 15kg calcium lignosulfonate, 10kg sodium gluconate, and 10kg sucrose were successively placed in a spiral stirring pot; stirred for 10-15 minutes to make the ingredients evenly distributed; using a packaging tape with a moisture-proof film inside Pack in time; obtain the powder product of the present invention.

Embodiment 2

[0034] 75kg naphthalene sulfonate formaldehyde condensate (NaSO 4 The content is less than 5wt%), 9kg calcium lignosulfonate, 8kg sodium gluconate, and 8kg sucrose are successively placed in a spiral stirring pot; stir for 10-15 minutes to make the ingredients evenly distributed; use a packaging tape with a moisture-proof film inside Pack in time; obtain the powder product of the present invention.

Embodiment 3

[0036] 70kg naphthalene sulfonate formaldehyde condensate (NaSO 4 content of less than 5wt%), 12kg calcium lignosulfonate, 8kg sodium gluconate, and 10kg sucrose were successively placed in a spiral stirring pot; stirred for 10-15 minutes to make the ingredients evenly distributed; using a packaging tape with a moisture-proof film inside Pack in time; obtain the powder product of the present invention.

[0037] The admixture of the present invention and its concrete performance test are carried out according to national standards and industry norms. The following tests used the concrete composite admixture powder product prepared in Example 3, naphthalene sulfonate superplasticizer (FDN), P.O 42.5 medium heat cement, secondary ordinary fly ash, river sand (medium sand), river sand pebble.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com