Large arc casting calibrating method

A calibration method and an arc-shaped technology are applied in the field of calibration of large arc-shaped castings, which can solve the problems of complex tooling equipment, potential safety hazards, and difficult tooling, etc., and achieve the effects of low cost, no potential safety hazards, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

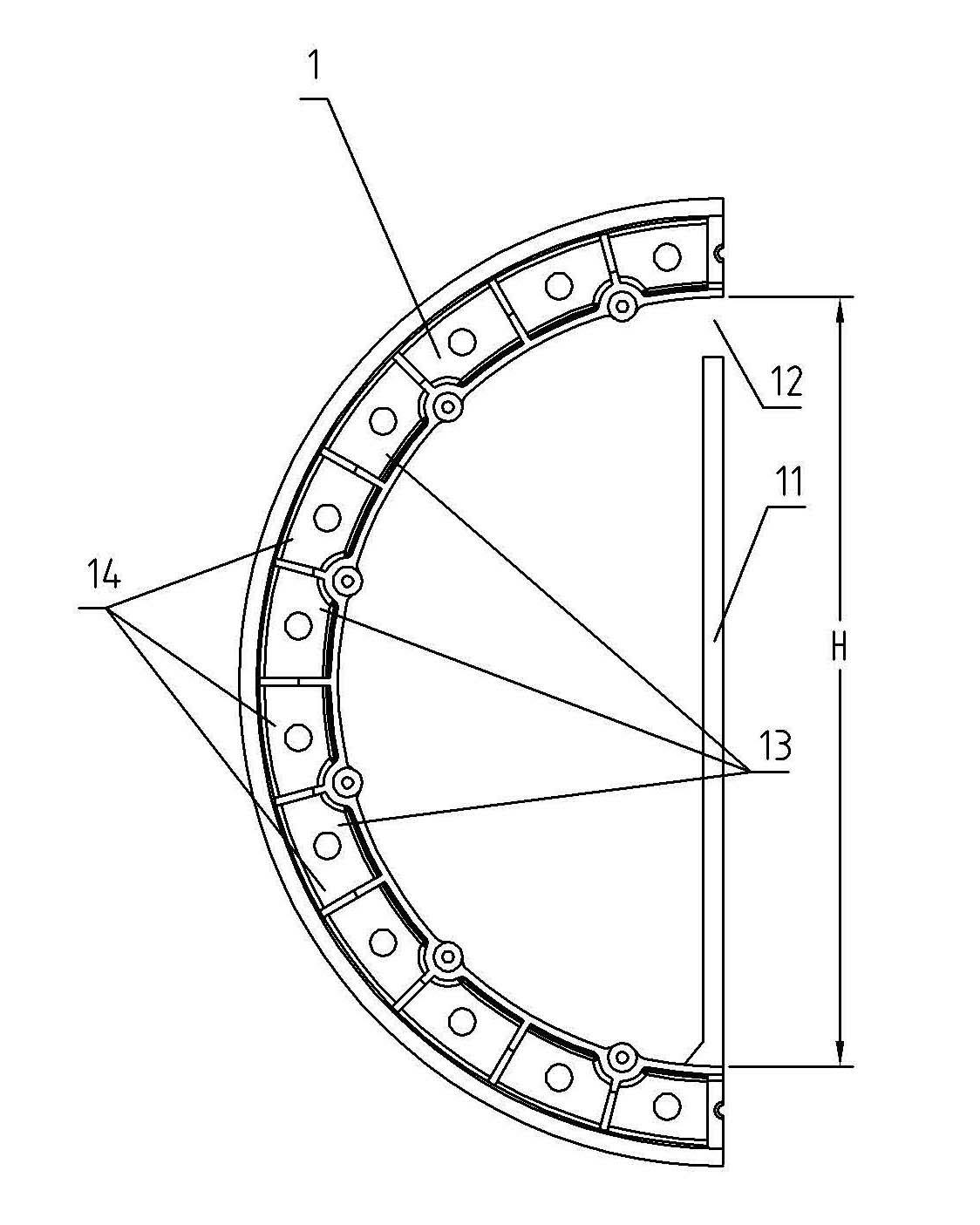

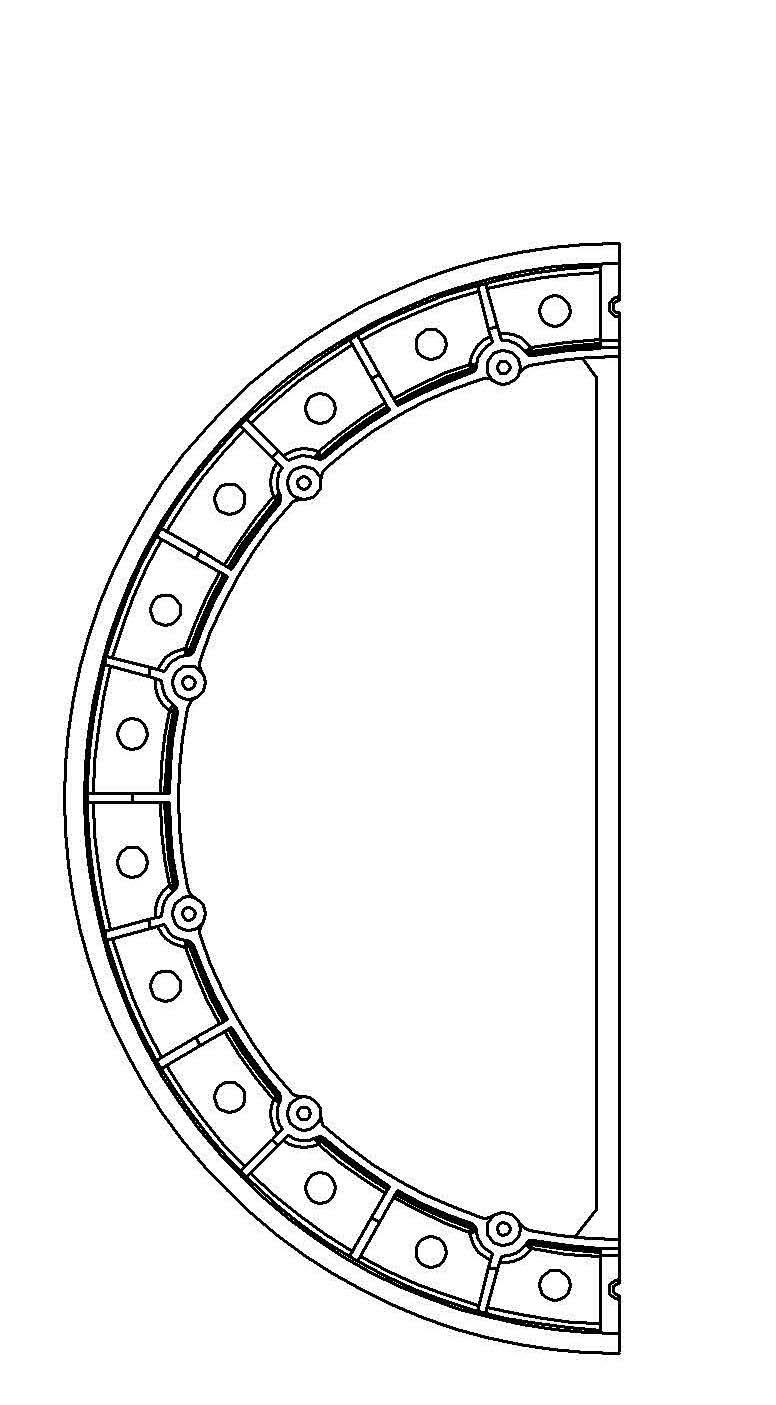

[0038] Such as Figure 1-2 As shown, a kind of rotary kiln half gear casting, material ZG35SiMn, blank weight 20500kg, surface hardness requirement is HB190~230, inner circle size Φ7220mm, wheel flange thickness 190mm, the design requires that the wheel flange thickness should be uniform after processing, and its opening deviation should not be allowed If it exceeds 5% of the design size on the drawing, it is found that the opening size is about 30mm away from the cross-line measurement and needs to be corrected.

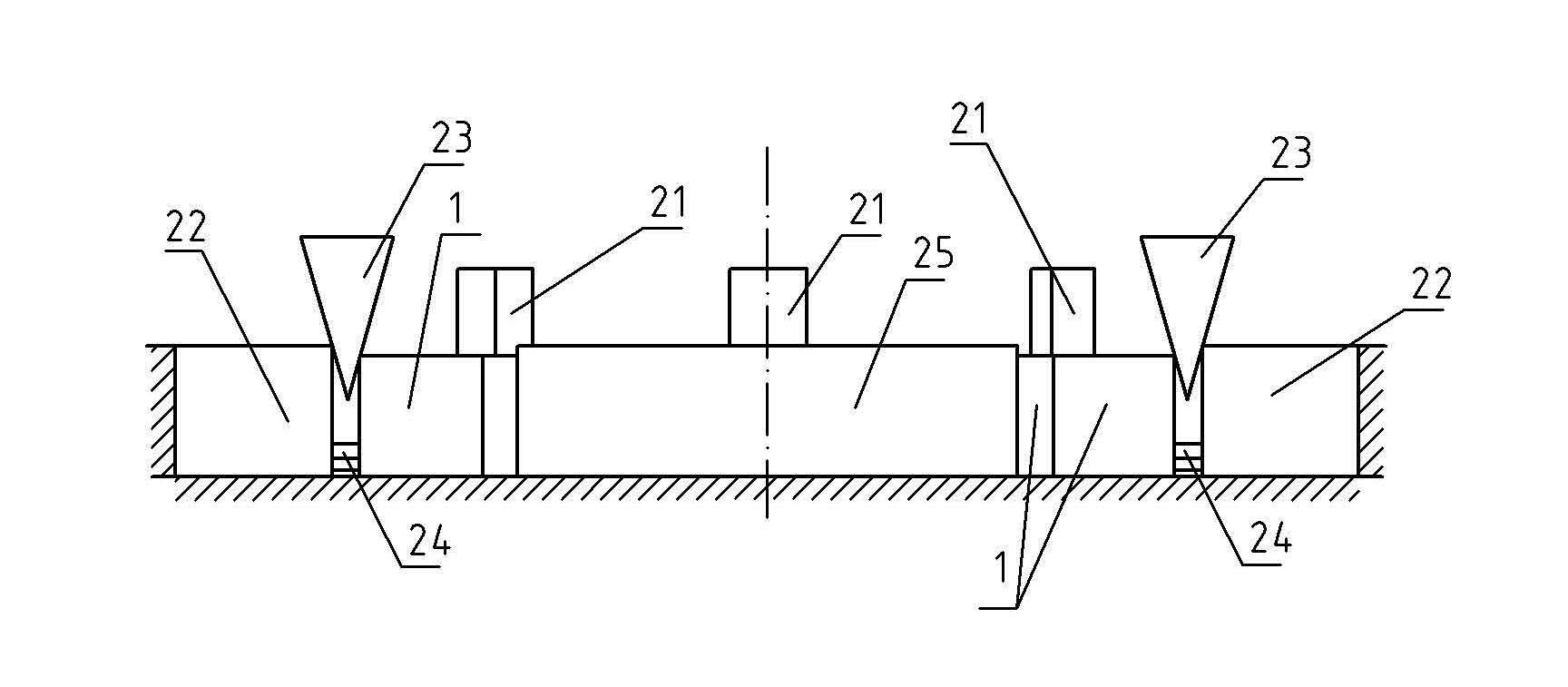

[0039] First cut one end of the brace 11, leaving a gap of 50-60mm. The whole is heated to 500-550℃ for 8h, then it is quickly hung out of the furnace and placed on a flat plate. figure 1 The shown inner zone 13 is evenly blown and cooled, and the size of the opening is measured to find that the size is shrinking (that is, the size becomes smaller). When the size is reduced to about 38mm (including the linear expansion size), the gap 12 is filled with wedge iron or thin...

Embodiment 2

[0041] Such as Figure 1-2 As shown, a rotary kiln half gear casting is made of ZG42CrMo, the rough weight is 20500kg, the surface hardness is required to be above HB200, the outer circle size is Φ7600mm, and the rim thickness is 180mm. The design requires that the thickness of the rim after processing should be uniform, and the opening deviation should not be allowed. It is more than 5% of the size shown in the figure; the opening size of the rotary kiln half-gear castings is found to be shrunk by about 60mm after the crossed measurement, and correction is needed.

[0042] First cut one end of the lacing bar 11, heat the whole into the furnace and heat it to 500~550℃ for 8.5h and then hung it off quickly. At the same time, put a pile of coke on the flat ground and ignite it with an oxygen-propane flame, insert a duct for ventilation to keep burning ;will figure 1 The inner zone 13 shown is placed flat on the burning coke and heated, and the movable air pipe pair is held manually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com