Cable with composite carbon fiber stranded wire reinforced core for power transmission line and manufacturing method thereof

A composite stranded wire and transmission line technology, applied in power cables, cable/conductor manufacturing, circuits, etc., can solve the problems of low comprehensive strength and difficult manufacturing, and achieve simple and easy methods, low slip, and low line loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

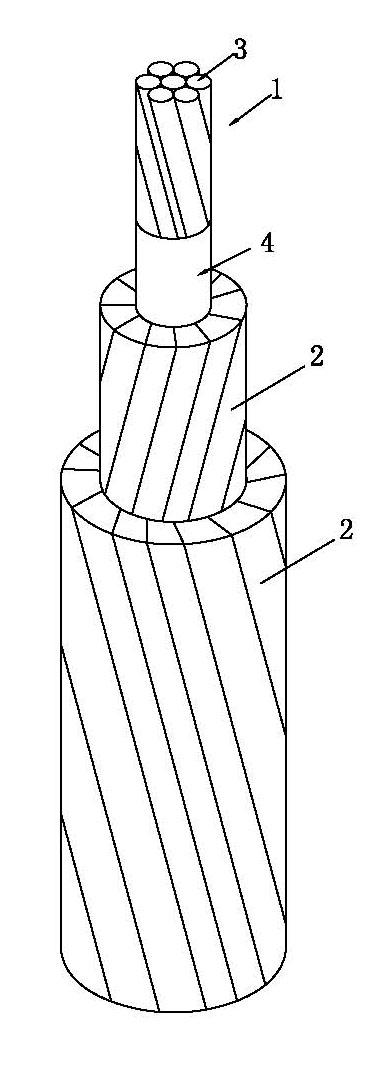

[0030] Such as figure 1 shown.

[0031] A carbon fiber composite stranded wire reinforced core cable for transmission lines, which is composed of a core wire 1 acting as a load bearing and at least one layer (two layers in the figure) of a conductive metal wire 2. The core wire 1 is wrapped in a metal In the conducting wire 2, the core wire 1 is composed of a plurality of carbon fiber composite cores 3, and each strand of the carbon fiber composite core is obliquely twisted and bonded into one body. Between the surface of the carbon fiber composite stranded wire core and the aluminum conductor, there is a protective layer 4 of glass fiber tape for insulation. The core wire 1 is composed of at least seven carbon fiber composite cores 3 with a diameter of not less than 1 mm; the angle between each carbon fiber composite core 3 and the axis is not greater than 10 degrees. The metal wire 2 is an aluminum wire, which is obliquely extruded and wrapped around the core wire 1 by a p...

Embodiment 2

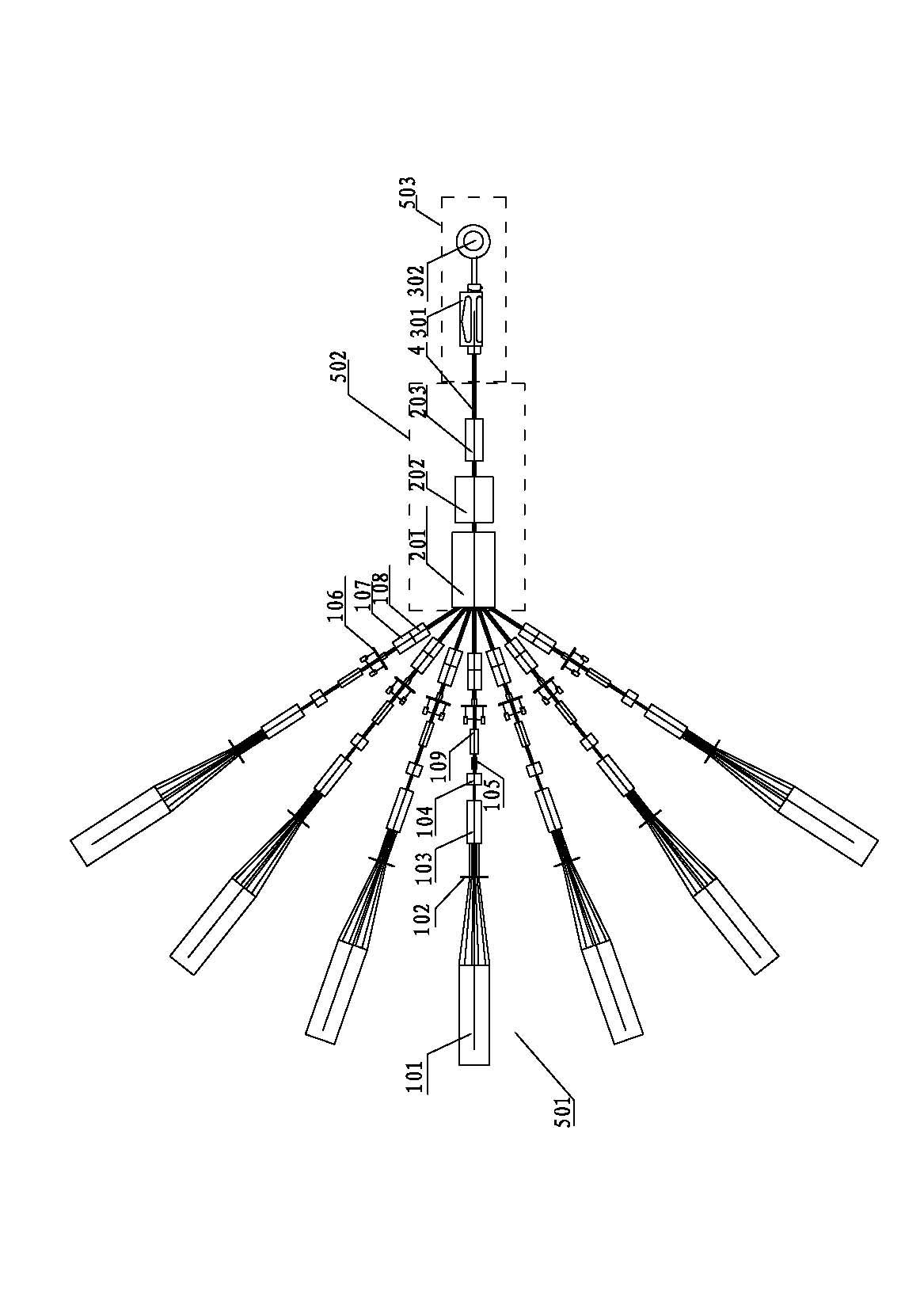

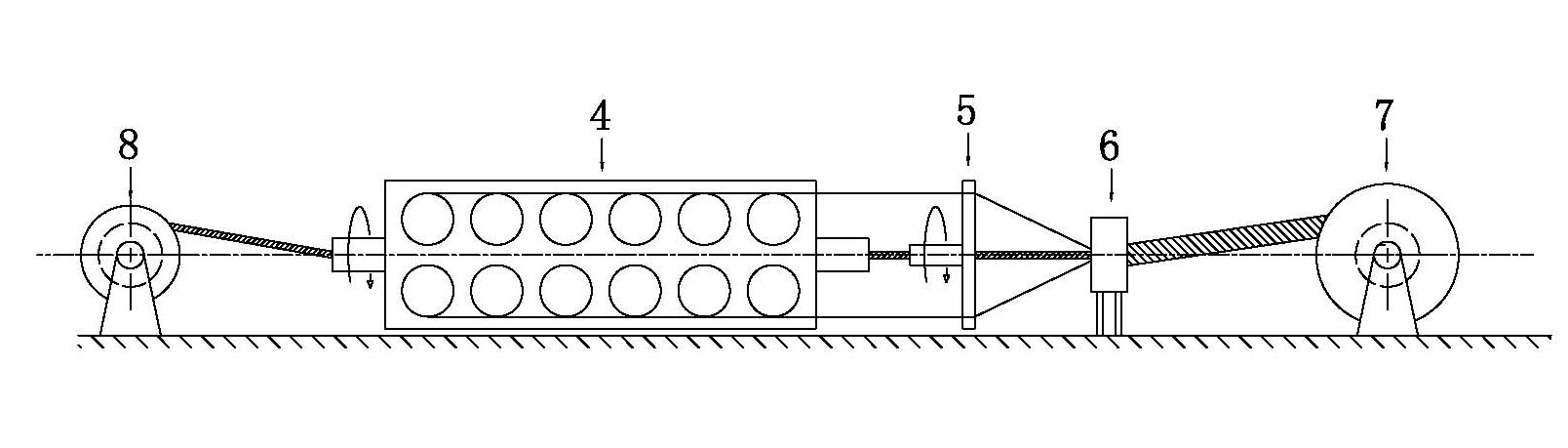

[0033] A method for preparing a carbon fiber composite stranded wire reinforced core cable for transmission lines, comprising the following steps:

[0034] First, set the tension creel equal to the number of strands of the composite stranded wire, pull the carbon fiber out at a constant speed from each tension creel with tension display and centralized control of tension, and control the tension at 1~5kN;

[0035] Secondly, the carbon fiber on each tension creel is led out, the yarn is collected by the yarn collector to form a fiber bundle, and then introduced into a cycle oven to remove broken fibers floating on the surface of the fiber bundle to increase the volume ratio of continuous carbon fiber in the product and remove the fiber The moisture content in the fiber should be controlled to less than 3%, and the temperature of the cycle oven should be controlled at 400°C~500°C;

[0036] The third step is to send the dehumidified carbon fiber into the corresponding constant te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com